3-D Microemulsion® Bio-Barrier Rapidly Treats Cis-DCE and Vinyl Chloride Contamination and Maintains Reductive Dechlorination Over a 1,200-Day Period

CASE SUMMARY

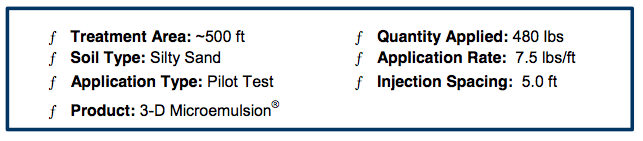

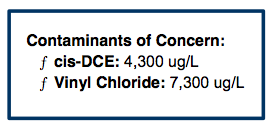

Cis-1,2-dichloroethene (cis-DCE) and vinyl chloride (VC) were migrating off-site at this commercial facility. A pilot test of enhanced anaerobic bioremediation was performed to determine if a bio-barrier using 3-D Microemulsion, a form of HRC Advanced®, could effectively reduce the cis-DCE and VC contamination before it moved off-site. The remediation design included the subsurface injection of 3-D Microemulsion upgradient of contaminated well MW-9.

TECHNOLOGY DESCRIPTION

Reductive dechlorination is a process used to degrade certain contaminants in groundwater (e.g., cis-DCE and VC) to ethene. 3-D Microemulsion is a highly effective agent to facilitate this process. 3-D Microemulsion is composed of free lactic acid, controlled-release lactic acid (polylactate), and certain fatty acid components esterified to a carbon backbone molecule of glycerin. When injected into contaminated soil and groundwater, 3DMe produces a sequential, staged release of its electron donor components. The immediately available free lactic acid is fermented rapidly while the controlled-release lactic acid is metabolized at a more gradual rate. The fatty acids are converted to hydrogen over a mid- to long-range timeline giving 3DMe an exceptionally long electron donor release profile. This staged fermentation provides an immediate, mid-term, and very long-term controlled release supply of hydrogen (electron donor) to fuel the reductive dechlorination process.

REMEDIATION APPROACH

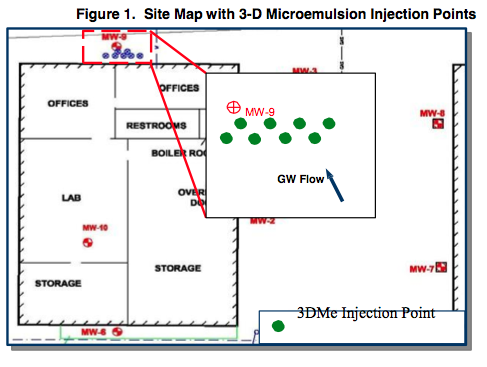

The objective at the site was to demonstrate the ability of 3-D Microemulsion to prevent the off-site migration of cis-DCE and VC by contaminant reduction. The reduction was to be achieved by the introduction of 3DMe into the subsurface through 8 injection points spaced 5 feet apart (Figure 1).

RESULTS

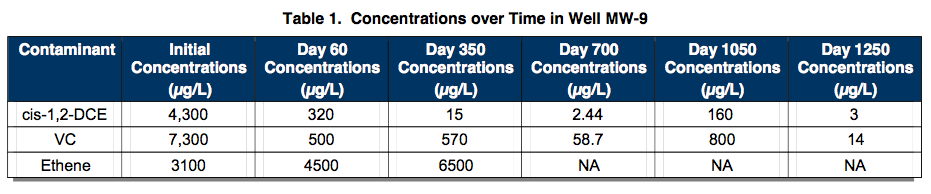

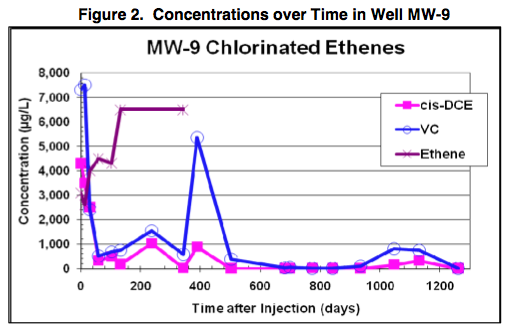

Within 60 days of the application of 3-D Microemulsion, concentrations of the target contaminants were significantly reduced (Table 1 and Figure 2). Over the 1,200-day monitoring period, cis-DCE was reduced by a magnitude of 3 from 4,300 to 3 micrograms per liter (μg/L). VC was reduced by 2 orders of magnitude from 7,300 to 24 μg/L, interrupted briefly by an anomalous spike likely to be laboratory error. As a result of this process, ethene concentrations increased by 102 percent, from 3,100 to 6,500 μg/L, after 130 days (a clear indication of complete dechlorination). Elevated levels of ethene were maintained for more than 300 days until ethene monitoring ended at Day 350 (Figure 2)

CONCLUSION

Overall, the results of this pilot test clearly show that when using 3-D Microemulsion, chlorinated ethene degradation via enhanced reductive dechlorination can be achieved both rapidly (60 days after injection) and successfully maintained over the long term.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español