Combined DPE System and HRC Treat TCE and Freon in Tight Soils

SUMMARY

Site investigations completed at a former manufacturing facility indicated significant amounts of volatile organic compounds (VOCs) in the vadose zone and shallow groundwater. The plume originated beneath an on-site structure with concentrations of trichloroethene (TCE) and Freon 113 as high as 3,000 parts per billion (ppb) and 220 ppb, respectively. In order to reduce the impact to groundwater from the vadose zone, a dual-phase extraction (DPE) system was installed for the initial phase of remediation. The DPE system removed a significant amount of TCE and Freon 113 from the source area and eliminated further transport to groundwater. However, the hydraulic gradient changed as a result of the DPE system and pulled in additional cross gradient Freon which increased concentrations. In order to achieve site closure, the DPE system was shutdown and the remaining residual VOCs were treated via enhanced anaerobic biodegradation using Hydrogen Release Compound (HRC®). The HRC application was expected to reduce TCE and Freon 113 concentrations in groundwater to the cleanup goals and act as a reactive barrier to inhibit migration to downgradient areas.

TREATMENT APPROACH

A subslab soil gas investigation was conducted at the site to assess the vapor concentrations of VOCs present in the soil underlying the on-site office building. Although the results of this investigation did not correlate to indoor air concentrations that would be a human health concern, a passive subslab soil gas ventilation system was installed as a further protective measure for site occupants. A total of three subslab vent ports were horizontally constructed beneath the building’s concrete foundation, with each port consisting of 6-feet long, 3-inch diameter perforated pipe wrapped in a filter sock and sealed in place (Figure 1).

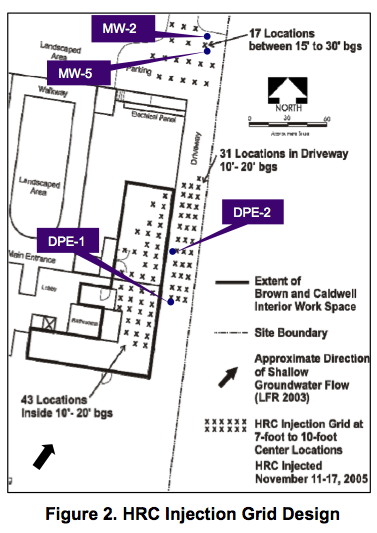

To treat the remaining groundwater contamination and bring the site to closure, an in-situ application of HRC was performed. An initial injection using HRC Primer was applied prior to HRC in order to reduce concentrations of competing electron acceptors such as nitrate and sulfate. HRC was then applied beneath the on-site structure and along the east perimeter of the building (Figure 2). An additional barrier application was injected downgradient to prevent off-site migration.

HRC APPLICATION

- Application Type: Grid & Barrier

- Product Applied: HRC®

- Quantity Applied: 600 lbs HRC Primer; 12,240 lbs HRC

- Product Cost: ~$70,000 (HRC Primer + HRC)

- Soil Type: Silt and Silty Sand

- Groundwater Velocity: Low Permeability

- Depth to Groundwater: 7-10 feet

RESULTS

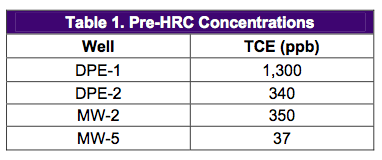

Prior to the HRC injection, TCE concentrations had been increasing over the previous 6 months (Graph 1). A high of 1,300 ppb, observed in DPE-1, indicated a flux of contamination occurring within the subsurface as a result of the DPE system shutdown. Approximately 5 months after the HRC injection, TCE declined to 7.5 ppb, a 99% reduction. Similar reducing trends were observed in monitoring wells DPE-2, MW-2 and MW-5 as concentrations were reduced to below 150 ppb in each well.

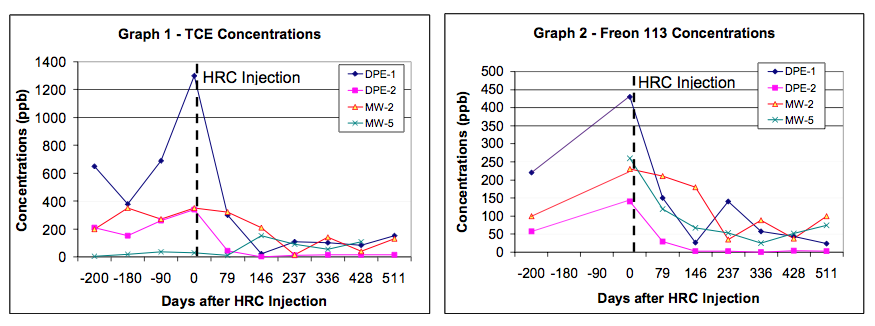

Similarly, an influx of Freon was observed in response to the DPE system shutdown just prior to the HRC injection (Graph 2). Concentrations declined rapidly over the next 6 months following the application as Freon declined from 430 ppb to 27 ppb in DPE-1. Over the next 17 months Freon was reduced by as much as 98% to below 100 ppb in all wells.

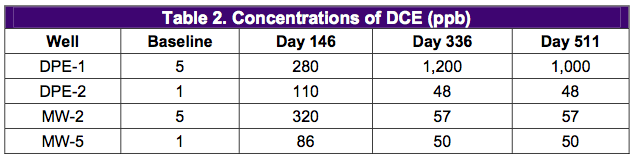

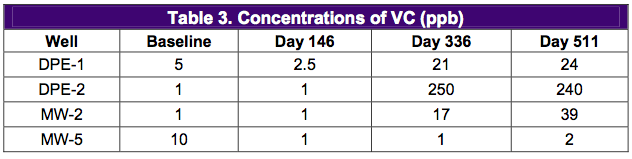

An increasing trend was also observed in total organic carbon (TOC) and metabolic acids corresponding to the decline in TCE and Freon. Concentrations of DCE, which had not been previously sampled above the detection limit, also increased (Table 2). As DCE concentrations began to decline, elevated levels of VC were observed (Table 3). Little to no ethene was detected.

A second application was applied 2 years after the initial HRC application to continue DCE and VC reduction. Approximately 6,200 pounds of HRC was applied using 91 injection points, similar to the original design in Figure 2. As monitoring continues, it is expected that the follow up application will reduce concentrations to the cleanup goals.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español