Hexavalent Chromium Barrier Treatment Protects River

Summary

w_Reg_20916_MRC_8_inj-rig_UKOn an industrial estate in Ravensthorpe, West Yorkshire, a leak from a storage tank in a chrome-plating works, had resulted in contamination of the underlying groundwater. The contamination was found to be migrating off-site, under neighbouring properties, towards a nearby river. Regenesis was employed to design and install a barrier to protect the river for a guaranteed 12 months in order to allow the building to be cleared of other tenants prior to demolition and source removal.

Design & Application

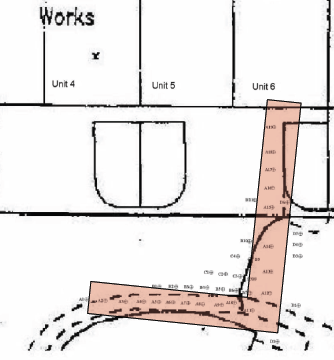

Metals Remediation Compound (MRC) was used to immobilise the contamination by reducing soluble hexavalent chromium into solid, non-hazardous trivalent chromium, which settled out of the groundwater. The MRC was injected in an ‘L’ shaped barrier through the apron and road outside of the industrial unit. The corner of the ‘L’ consisted of three rows of direct push injection locations, in order to provide a wide treatment zone where maximum contaminant influx would occur. The MRC was applied using direct push injection in gravels, from the top of the groundwater at 5 m BGL to 12 m BGL (rock-head).

What’s Special?

- Within weeks of application, the barrier prevented the movement of hexavalent chromium contamination towards the river. Concentrations of 10,000 μg/L Cr(VI) were reduced by >98% to <200 μg/L 5m downgradient of the barrier and non-detect at the river.

- Regenesis provided a warranty on the barrier for a period of 12 months after the application, however the MRC barrier would remain effective between 2 to 3 years.

- The controlled-release mechanism of MRC meant that offsite receptors were protected for an extended period from a single, low-cost injection.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español