Treatment of chlorinated solvents at a complex site with sensitive receptors

Summary

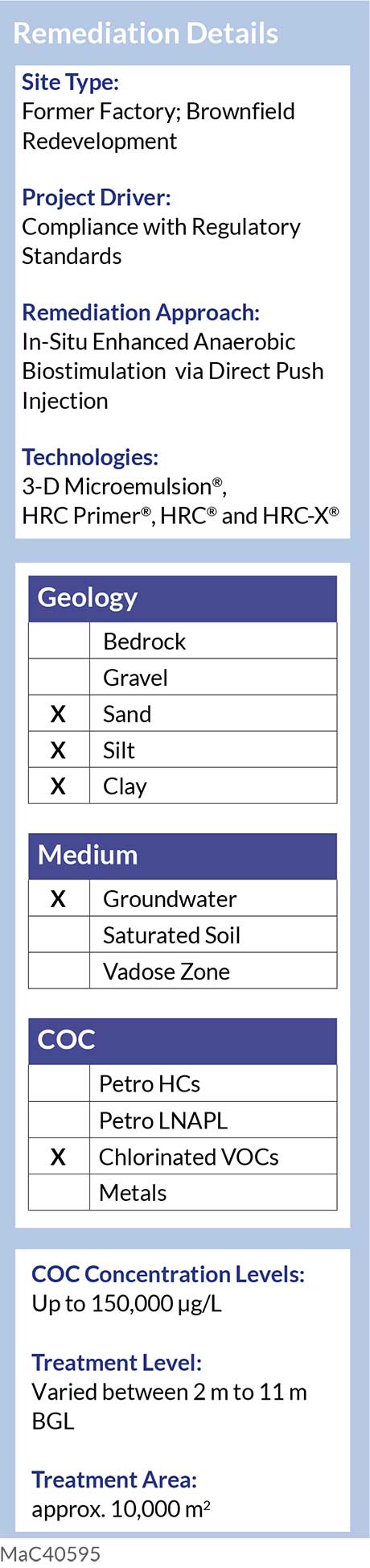

Chlorinated solvents were used for a number of years at a former manufacturing facility in Italy. This has resulted in contamination of the groundwater underlying a large proportion of this 6ha site. Groundwater concentrations of up to 155,000 μg/L TCE presented an unacceptable risk to both on- and off-site receptors and it was determined that active remediation was required. A remediation approach was designed based on targeted excavation of highly impacted soils, plume treatment through Enhanced Reductive Dechlorination (ERD) and the installation of a down-gradient treatment zone to prevent further contamination of the river beyond the site boundary.

Treatment

ERD of the chlorinated solvents was achieved through a grid of direct push injections, introducing a suite of REGENESIS products into the subsurface. The site was first divided into different areas based on the distribution of contamination and differing permeabilities. A tailored product mix and dosage was then created for each area. Our wide-distribution substrate (3DMe) was used in the up-gradient zones on a widely spaced injection grid, to minimise injection cost, while providing optimum treatment of the contamination. The down- gradient treatment zone required application very close to the river at the site boundary. A mixture of low volume, high viscosity (HRC) products were used here to prevent contaminant egress from the site for up to five years from a single injection while remediation of the source area is completed upgradient.

What’s Special?

- Over 500 direct injection points were used to apply a range of substrates across 10,000 m2 of the site;

- The on-site activities were successfully completed in only 6 months. Remediation will occur over several years, with no further site attendance or operational costs beyond validation sampling;

- Remediation is intended to reach stringent clean-up targets at both the site boundary and within the property were required by the regulator;

- The wide range of REGENESIS injectable substrates allowed for a tailored design solution. Product mix and dosages were designed for each part of the site, providing the most accurate and cost effective solution.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español