Ongoing Project in France – Results to Date

Introduction

Enhanced Reductive Dechlorination (ERD) through biostimulation and redox manipulation is a well-established treatment method for chlorinated solvent contamination in groundwater. However, it is sometimes considered inappropriate where natural conditions are not already conducive to anaerobic attenuation, such as highly aerobic aquifers or fast-flowing groundwater. The use of microbial assays or PCR testing can potentially reinforce this view, when baseline sampling shows little or no evidence of the presence of dehalorespirators or active reductive dechlorination. However, ERD can be achieved in these situations through the creation and maintenance of the ideal redox conditions, coupled with a long term supply of terminal electron donors. Regenesis has successfully remediated many sites via ERD, where initial conditions appear unpromising, using Hydrogen Release Compound (HRC) and 3-D Microemulsion (3DMe) substrate technologies. This case study exemplifies this approach and presents data from a site where treatment is ongoing.

Fig. 1 Metal fabrication works

The Site

The groundwater under an active metal fabrication works in eastern France was impacted with tetrachloroethylene (also known as perchloroethylene (PCE)) following historic leaks and spillages at the facility. The underlying aquifer comprised a highly permeable sandy formation, which allowed a high groundwater seepage velocity of greater than 300 m/year. This had resulted in an extensive dissolved phase plume forming on the site. The contamination extended over 260 m, with concentrations of up to 1,300 μg/L and no obvious source, although multiple areas were suspected. The contamination also extended from the top of the groundwater at 3 m BGL to approximately 10 – 13 m BGL (chlorinated solvents, having a high specific gravity and a low viscosity, tend to move downwards through the water column). The groundwater in ux was also highly aerobic, hence very little natural biological attenuation of the PCE was occurring.

The main risk from the PCE plume was due to its migration beyond the site boundary into a nearby fishing lake. Where the contaminant concentrations could actually be measured in the lake water (32 μg/L PCE). The contamination also potentially posed a human health risk to site.

Fig. 2 Impacted nearby fishing lake

Remediation Strategy

Studio Maffezzoli and Regenesis designed, and Ortec implemented, a safe, economical and cost effective in situ ERD strategy, which was new to this part of France.

Although no site specific target values were set for the project, the intention of the remediation strategy is to prevent offsite migration of the plume, thereby mitigating the impact to the fishing lake and secondary, and to reduce the risk to human health onsite.

There are several potential spill locations at the site and as the high seepage velocity has created a large plume with low concentrations, it has proved difficult to accurately delineate the source areas. The buildings and activity on the site have also made access for site investigation, difficult in some areas. Therefore, a staged remedial strategy has been adopted, with a series of barriers used to treat as much of the plume as can be accessed in an economical manner. As monitoring continues, it may be the case that more recalcitrant areas may be observed, which will help to give better resolution on the source locations. Further site investigation during the validation period can also then be used to determine if a second locally tailored dose may then be completed in these areas.

The remedial approach was also intended to minimise the disturbance to this busy, active facility. It was therefore decided to use 3D Microemulsion (3DMe) as this stimulates ERD from a single application for up to 5 years (although it may be expected to be slightly less in a fast flowing site such as this), minimises the number of injection locations and avoids the use of any physical abstraction equipment at the site.

Fig. 3 The buildings and activity on the site made access difficult in some areas

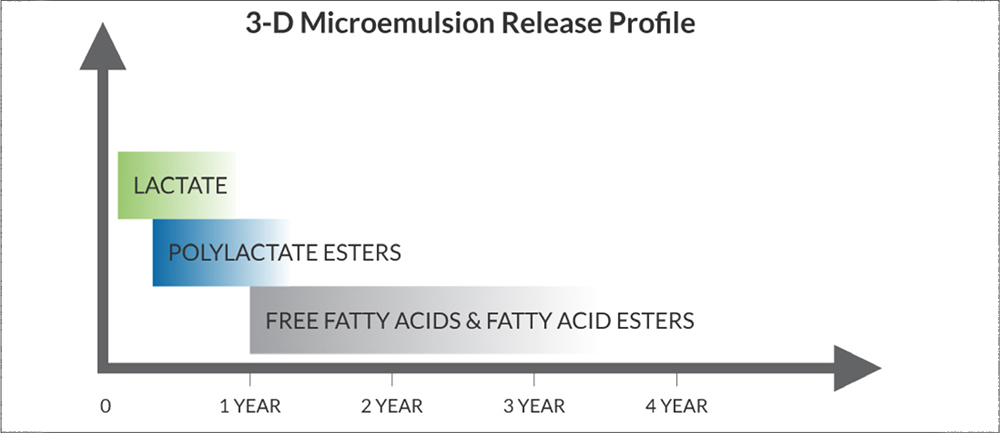

Fig. 4 3DMe Electron Donor Release Profile

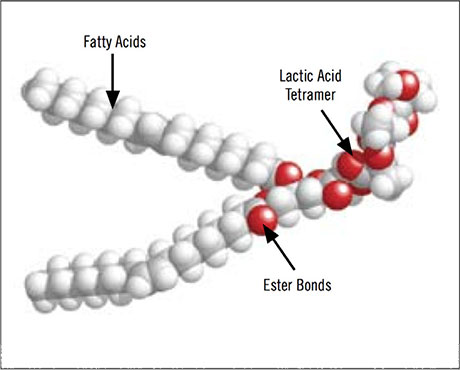

3DMe provides three stages of electron donor release from a single concentrate of specially designed polar molecules. When mixed with water on site, 3DMe forms a high-volume microemulsion, without the requirement of emulsifiers. Upon injection into the groundwater, 3DMe initially moves out into the formation and adsorbs to the soil particles. As the molecule is designed to be appropriately soluble, it then gradually dissolves back into the groundwater, where it ferments to drive ERD, but also reaches its critical micelle concentration (300 ppm), reforms as a microemulsion and moves further out from the injection point.

This process repeats to ‘self-distribute’ the 3DMe over large distances within the subsurface, without it washing away. This mechanism allowed for wider injection spacing which reduced the number of injection locations. This then allowed both the cost and disruption to the site to be minimised. The ability of 3DMe to coat the subsurface without being washed away, whilst still being soluble enough to provide an effective terminal electron donor concentration in the groundwater, made it ideal for this fast flowing site.

Fig. 5 3DMe Molecular Structure

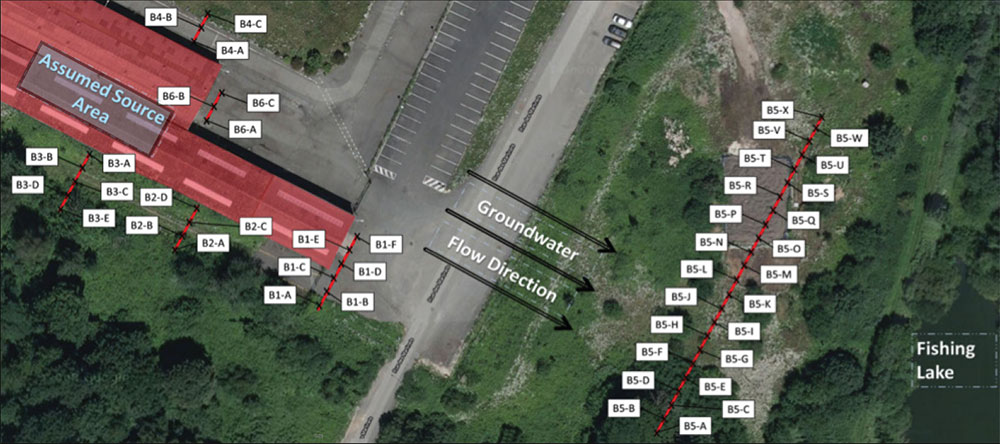

Fig. 6 Treatment zones (‘barrier’) locations

The first phase of the treatment was applied in March 2012. 3DMe was applied in six ‘barriers’ installed perpendicular to the flow of the groundwater. Each injection involved driving a direct push injection rod into the subsurface and applying the requisite dose across the vertical target zone. The injections were then repeated in a row across the width of the plume. The 3DMe then self-distributes from these locations to create a wide radii of influence (ROI), which interlock, creating an anaerobic treatment zone in which reductive dechlorinating bacteria can flourish.

As the groundwater flows through the treatment zones (or ‘barriers’, see Fig. 6), the dehalogenators biologically degrade the dissolved contamination through reductive dechlorination, enhanced through the creation and maintenance of ideal redox conditions and a continual supply of dissolved hydrogen. A barrier approach was chosen to minimize costs whilst still ensuring treatment of the entire plume, through migration of contamination between barriers into the next treatment zone downgradient. In order to remediate a plume of 12,000 m2 to a depth of 13 m BGL, the treatment comprised a single injection into 45 points, spaced 4 m apart within 6 barriers. The works took only 15 days to complete, with in situ treatment expected to last several years.

Results

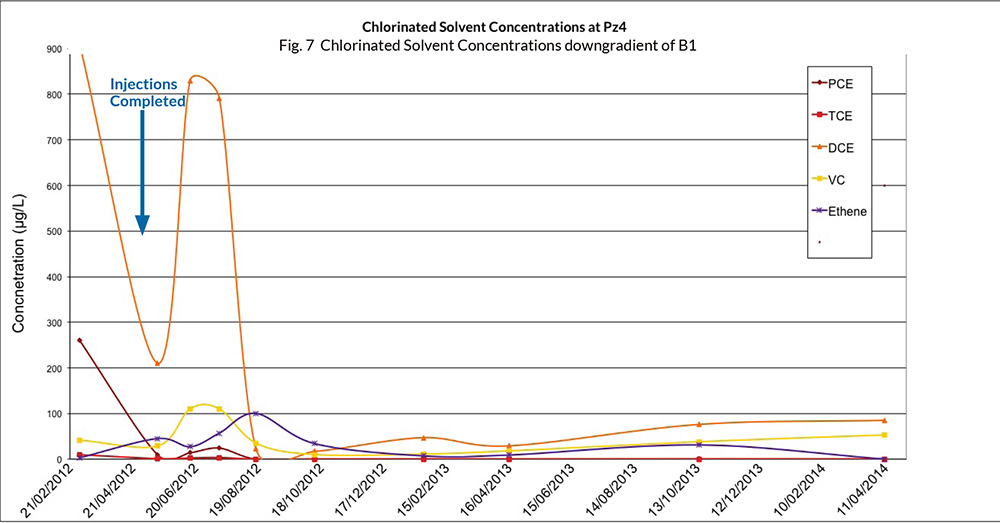

Following the application, a rapid reduction in PCE concentrations was seen in all wells downgradient of the barriers across the site. In Fig. 7, it can be seen that concentrations of PCE are non-detect after only 5 months. The application resulted in the sequential production and breakdown of daughter products and an increase in ethene production showing that full reductive dechlorination is being achieved.

Ongoing low levels of DCE and VC downgradient of the barrier show that there is a small residual in ux of PCE/TCE into the barrier, which is being fully dechlorinated. Ortec are completing further SI in order to locate the source and target further treatment.

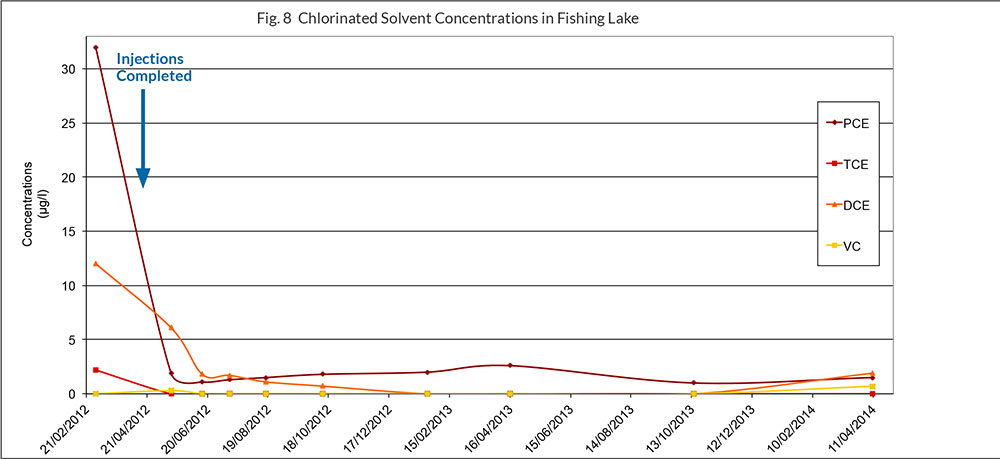

In Fig 8, it can be seen that the PCE concentrations in the fishing lake were rapidly reduced after the application and have remained low ever since. The breakdown products have also reduced to almost non-detect and remain at a very low level. With the onsite barriers remediating the contamination before it reaches the lake, the residual concentrations in the lake water may be expected to attenuate over time.

Conclusions

24 months after treatment, the concentration of PCE onsite has been dramatically reduced on the site and within the fishing lake, without the build- up of daughter products. In the monitoring locations downgradient of the onsite barriers, parent compound concentrations have been reduced to non detect, preventing any further contaminant egress from the site. With only 15 days of onsite works, two years of remediation has so far been achieved, overcoming challenging aquifer conditions to successfully create and maintain ERD treatment.

Further intrusive investigation has recently started to locate any residual source areas on the site, which can then be accurately targeted. In the meantime, the 3DMe product applied on the site will continue to remain active for many months/years to come, continuing to degrade any contaminant in ux and protect both the offsite environment and site personnel.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español