PlumeStop pilot proves stringent concentration targets are achievable

PlumeStop preparation for injection

Summary

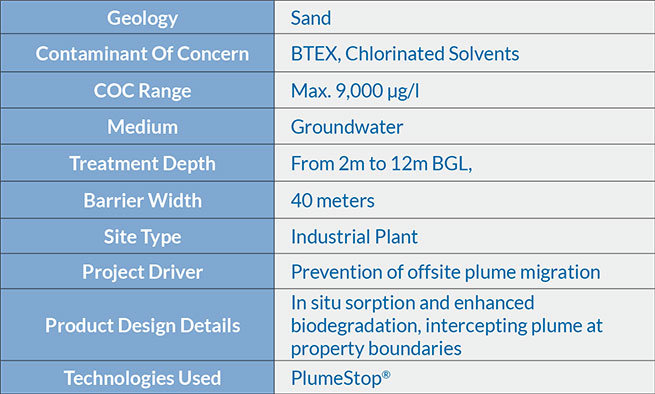

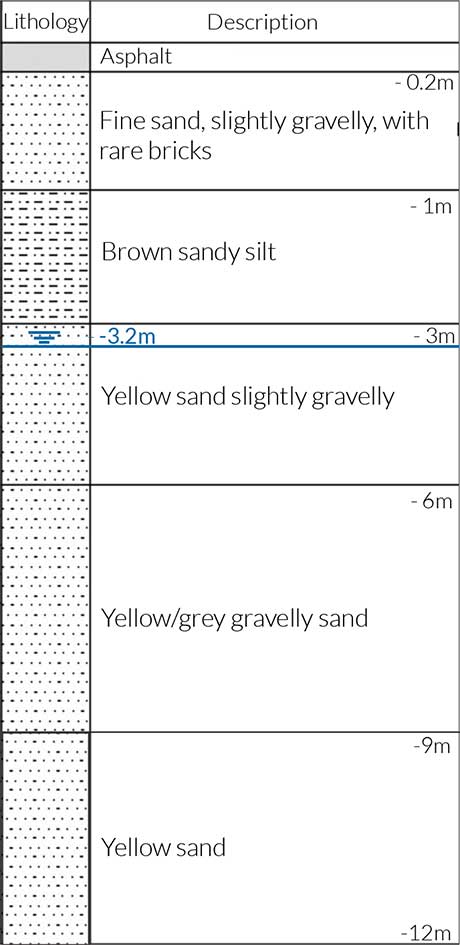

At an active industrial plant in Italy, a site investigation uncovered historic contamination relating to occasional spillages during the handling of chemicals. Two interconnected plumes have been detected: One widespread plume consisting of chlorinated solvents at low concentrations (<1,000 μg/l) spreading wider to approx. 40 meters at the property boundaries.

The second plume partly overlaps with the first plume on one side, and consists primarily of BTEX at higher concentrations (9,000 μg/l). This plume tapers to around 10 meters wide at the site boundary, (the source of this contamination is located closer to the site boundary). Italian legislation prescribes compliance to very stringent targets for many organic contaminants, which makes remediation necessary at this site.

Remedial Design

Consideration was made for the installation of a pump and treat (P&T) system at the site boundary in order to hydraulically contain the contamination. This however would have resulted in high installation and operational & management costs, as well as disturbance of, and interference with, the ongoing commercial activities at the plant – an in situ, passive treatment has been selected.

REGENESIS has provided a remediation strategy focused on in situ sorption and biodegradation, using PlumeStop Liquid Activated Carbon technology in a barrier formation to treat the plumes and prevent offsite migration of the contamination.

Pilot Test

To date, a double pilot test has been carried out to evaluate the capability of the technology to reach the low remediation targets. Two different pilot areas have been selected:

- Area 1 is characterised by low chlorinated solvent concentrations of around 40 μg/l and traces of TPH;

- Area 2 shows high BTEX concentrations (approx. 9,000 μg/l), relatively high chlorinated solvent concentrations (1,000 μg/l) and the presence of TPH (700 μg/l).

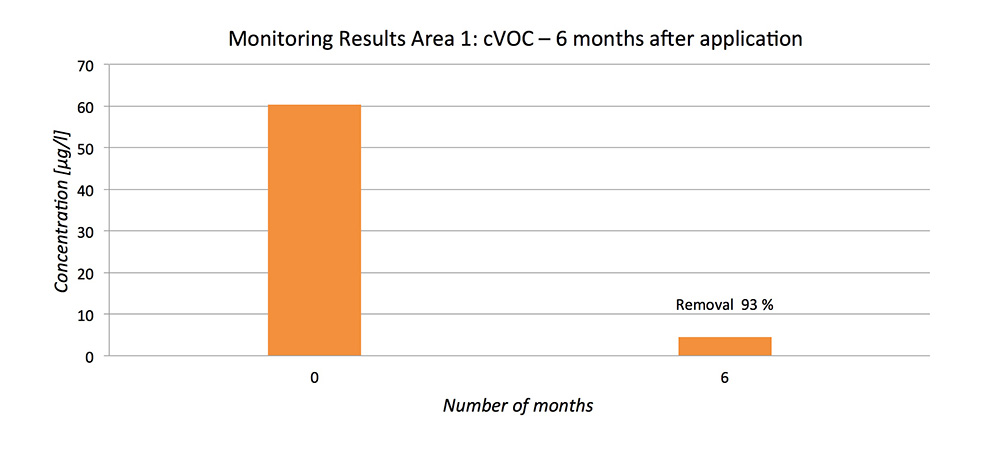

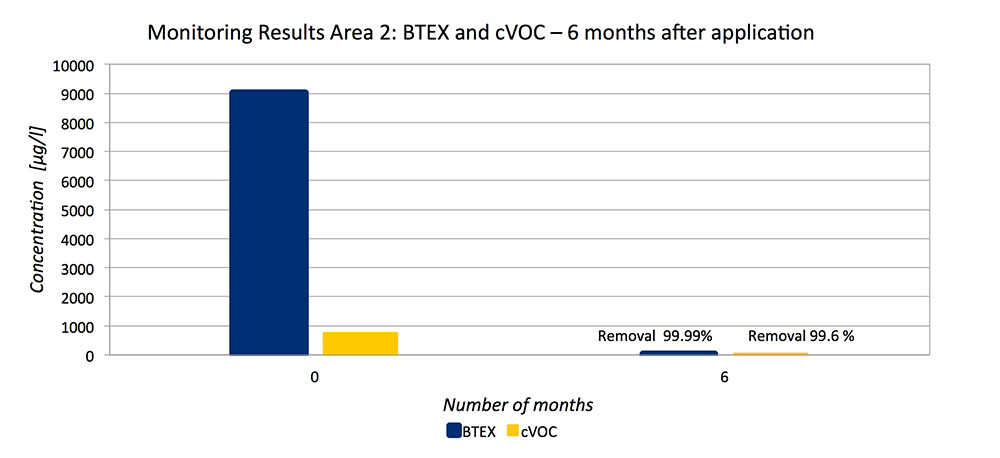

Pilot Test Results

Validation monitoring showed rapid and significant reduction in the contaminant concentrations in both pilot areas. Chlorinated solvent concentrations were reduced by 93% to 99.6% in both areas. The BTEX contamination in the second pilot was reduced by 99.99% to concentrations of <1ug/L, see graph below.

Monitoring Results for Chlorinated Solvent Concentrations and BTEX for Areas 1 and 2

Monitoring Results for Chlorinated Solvent Concentrations and BTEX for Areas 1 and 2

Full Scale

Presently the full scale design is being completed, comprising an active PlumeStop barrier at the site boundary. The barrier will be approx. 40m in width in order to target the contaminant concentrations at the centre of the plumes, where remedial targets are exceeded.

Conclusion

- The pilot test shows that PlumeStop can provide an effective treatment for petroleum hydrocarbons and chlorinated ethenes and that these treatments can be completed within the same site.

- As a result of the unique biodegradation mechanism of PlumeStop, the sorption sites within the PlumeStop matrix will be continuously regenerated. This allows the treatment to continue passively for decades, without the need for any additional applications in future.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español