Integrated geo-environmental solution allows for site redevelopment

Summary

Wildgoose Construction’s redevelopment of a former bus depot into commercial/retail, including a new public house for Marston’s, posed unique and complex challenges. Geotechnical and Environmental Associates Ltd (GEA) identified that each step in the solution process would have a follow-on effect, so a well thought-out, integrated approach was crucial for the project’s success.

Fig. 1 – PlumeStop barrier injection near site boundary

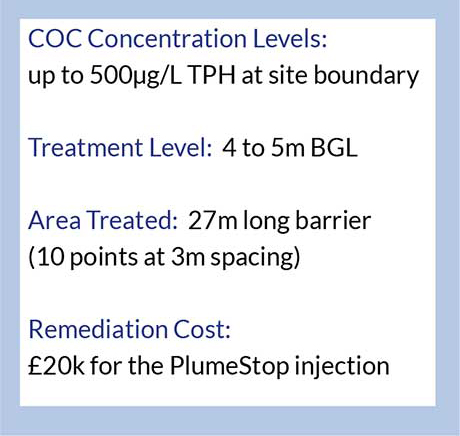

The site comprised a hillside covered by industrial waste from the Leblanc process comprising several metres of galligu above a black ash layer which was underlain by cohesive glacial till. Two geoenvironmental issues needed addressing:

- Stability: the galligu had a weak structure, with a ‘toothpaste’ consistency in parts;

- TPH contamination; leaking underground storage tanks (UST)s onsite resulted in fuel infiltrating the subsurface and moving offsite via perched water in an ash layer beneath the galligu. The downgradient boundary comprises a steep slope to the canal where the contaminated groundwater egressed at ground-level, polluting the waterway.

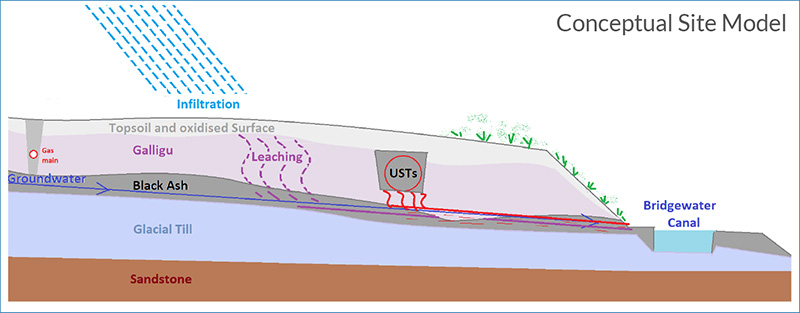

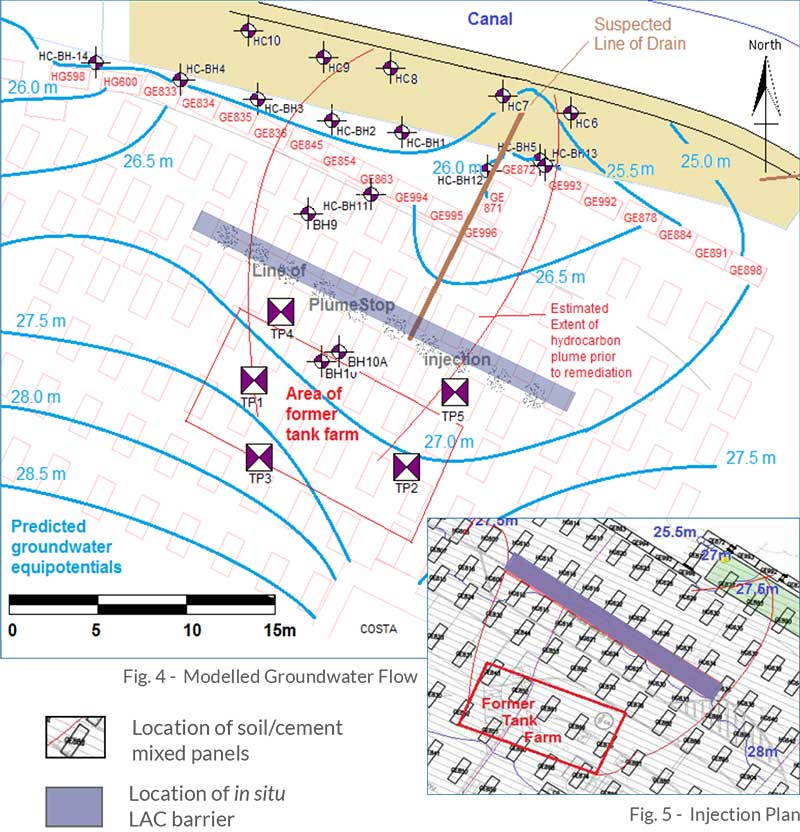

An integrated solution: Soil/cement mixed panels were used to support structures, with a soil/cement mixed mattress covering the entire site, as a load transfer platform. Installation of these panels altered the groundwater flow, which therefore needed modelling to ensure the contaminant treatment could be targeted accurately.

Modelling groundwater flow through anthropogenic waste and man-made installations presented a challenge, as models are designed for more homogeneous and isotropic conditions. However, it was shown that groundwater would be raised and channelled towards the panel ‘wall’ at the boundary. Here the groundwater would funnel through gaps at a higher velocity.

An innovative Liquid Activated Carbon substrate was used to integrate with the panels, which required no maintenance and provided effective treatment in the extremely bio-toxic environment created by galligu. This subsurface carbon-filter entirely prevented contaminant egress from the site.

Integrated Geoenvironmental Solution

The structure of galligu varied across the site: from fused crystalline ‘rock’ in upper areas, to a weak ‘toothpaste’ consistency at depth – unsuitable to build on. Previous settlement caused hydrocarbon leaks from broken pipes, resulting in the bus depot closure. Potential settlement prevented the use of a raft foundations. In addition, the presence of a high pressure gas main prevented the use of a piling solution. Therefore a soil/cement panel solution was piloted and then installed full scale by Deep Soil Mixing Ltd, using in situ mixing equipment (see figure 5 and 6).

Fig. 2 – Conceptual Site Model in Section

Fig. 3 – Remedial Strategy in Section

The geotechnical solution created a new challenge: to understand how the cement stabilised columns would alter the groundwater flow pattern across the site. This was crucial to know, in order to determine where contaminant egress may occur at the site boundary.

Galligu creates strongly alklaline, arsenic rich, reduced conditions in the subsurface. This inhibits biological degradation, resulting in ongoing persistence of TPH. This chemistry prevents typical remedial approaches to be taken as the remedial solution would have to: not react with the cement, galligu or ash; capture the hydrocarbons in the toxic conditions produced by the galligu; work for decades, until the residual secondary source is depleted, without power, pumping or further action.

When PlumeStop Liquid Activated Carbon (LAC) was chosen, the placement of this underground filter needed to be carefully considered. At the boundary, the groundwater flow was extremely fast through the gaps. Hence, by moving the barrier into the site, the slower groundwater allowed for a longer treatment time in the PlumeStop. The PlumeStop barrier length was guided by the modelling, to transect the entire contaminant plume. REGENESIS provided bespoke design work to match the predicted groundwater flow and contaminant levels (i.e. the contaminant flux).

Application

REGENESIS worked with GEA and their client to ensure the design matched their requirements. REGENESIS also managed and completed the injection works onsite using direct push injection, and then provided a completion report and warranty.

All work was completed on a busy construction site, with a high-pressure gas main and large easement.

Results

Following injection of the PlumeStop across the width of the predicted contaminant plume, the TPH concentrations at the site boundary were dramatically reduced by 98%. Although not the main focus of the treatment, low levels of PAH were also reduced to non-detect.

Fig. 14 – TPH concentrations at site boundary before and after PlumeStop barrier treatment

Conclusion

This integrated geoenvironmental solution was highly successful, delivering a number of key achievements:

- Galligu is often treated ex-situ, which was not practical in this situation. The soil/cement stabilisation approach provided an economical solution to the geotechnical problems presented by Galligu, whilst encapsulating the contaminants within it and minimising future leaching. Being a low disturbance technique, it also permitted treatment alongside a high-pressure gas main where piling was not permitted. Groundwater modelling of the altered flow pattern was required to allow the design of the remedial scheme. Due to the inevitable uncertainties associated with groundwater flow through the ash layer this modelling was carried out using a low cost electrical analogue modelling technique.

- The remedial scheme allowed the project to proceed within budget and was delivered on time.

- Treatment of petroleum hydrocarbon contamination in the presence of galligu has not been completed previously to our knowledge.

- This was the fourth use of PlumeStop in the UK and represents an imaginative and fully thought-through application that allowed highly effective remediation, protection of a public waterway and cost-effective geoenvironmental treatment of a busy and difficult site.

This project has won in the category ‘Best Conceptual Design’ in the Brownfield Briefing Awards 2018, and was shortlisted in the GE Awards 2018.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español