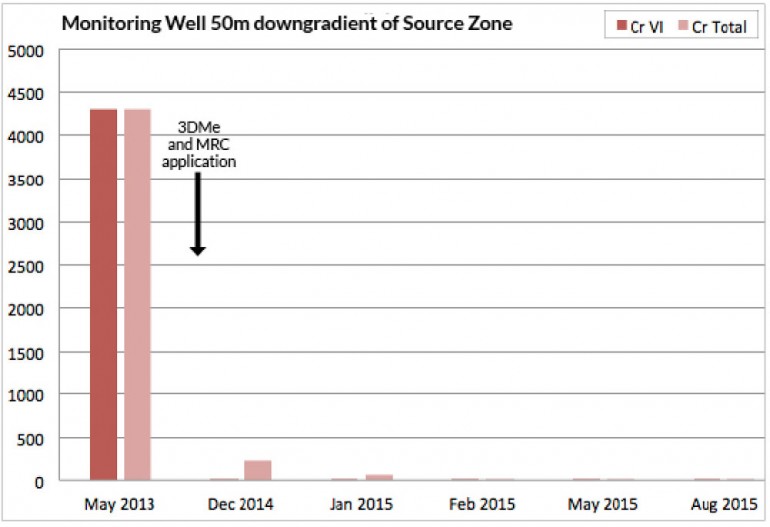

Source and Plume reduced to non-detect in 2 months

Summary

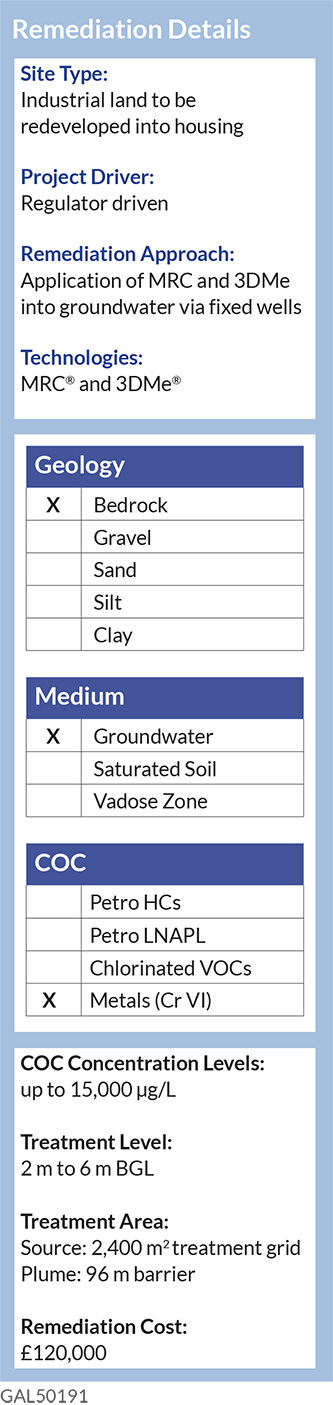

REGENESIS were retained to carry out the remediation design and site application works to treat groundwater impacted with hexavalent chromium (CrVI) on the site of a former saw mill.

Metals Remediation Compound® (MRC) and 3D-Microemulsion® (3DMe) were applied into the groundwater to provide rapid reduction and immobilisation of the CrVI present. Groundwater samples collected 2 months after application were analysed for CrVI, returning non-detect results.

Treatment

As the geology comprises weathered and fractured limestone, treatment was carried out via pre-installed treatment wells at a 5 m spacing in the source area and 6 m in the barrier.

MRC and 3DMe were co-applied into these wells to target the source area of contamination and to install a reactive barrier at the down-gradient edge of the site to protect a nearby watercourse. MRC and 3DMe provide a powerful combination of wide distribution and strong reducing and immobilising properties.

Results

The 3DMe/MRC application achieved rapid reductions from concentrations of up to 15,000ug/L CrVI to below detection limits within 2 months (See graph below). These low concentrations were then maintained throughout the validation period (ongoing).

What’s Special?

- REGENESIS’ injection team completed the site works ahead of schedule to allow the groundwork contractor to prepare the site for housing development.

- The use of MRC and 3DMe allowed for wide spacing of the injection wells and therefore lower drilling costs.

- The treatment approach achieved rapid reductions from up to 15,000 μg/L of Cr(VI) to non-detect within two months, expediting regulatory sign-off and unlocking the site for redevelopment

- Effective plume treatment will be maintained on the site for several years from this single application.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español