PCE and TCE Remediation at a Dry Cleaning Facility

SITE SUMMARY

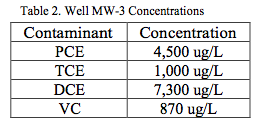

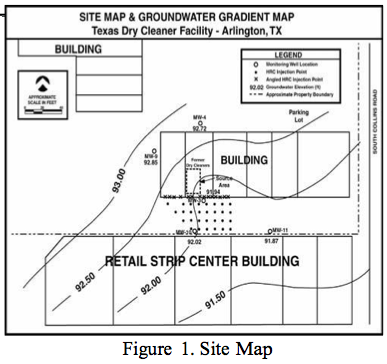

Subsurface investigations at this operating dry cleaner site revealed elevated levels of PCE and TCE in the site soils and groundwater (perched aquifer). Soil remediation was accomplished via over-excavation in June of 1998. Accelerated bioremediation using HRC was selected to treat the groundwater contamination. The HRC application approach was chosen because it minimized disturbance to site operations. Most importantly, the site was granted closure status 17 months after initial HRC treatment.

REMEDIATION APPROACH

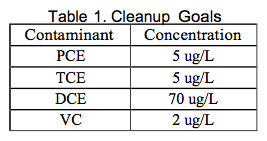

- Remediation Objective: Reduce concentrations of chlorinated aliphatic hydrocarbons to target concentrations at the entire site. See Table 1.

- Application Type: Grid (Direct-Push Injection)

- Product: HRC

- Quantity Applied: 10,020

- Application Rate: 10.37 lb/ft

- Injection Spacing: 5 ft on-center

- Product Cost: $62,340

SITE CHARACTERISTICS

General

- Name: Arlington Strip Mall

- Location: Arlington, Texas

- Industry: Dry Cleaning

- Contaminants of Concern:

Hydrogeology

- Treatment Area: 3,000 ft2

- Soil Type: Clay

- Groundwater Velocity: 0.055 ft/day

- Groundwater Flow Direction: Southwest

- Depth to Groundwater: 7 ft

RESULTS

CONCLUSION

In an attempt to successfully treat the difficult to reach source area, directly beneath the facility, and to minimize building disturbance, 15 HRC injection points were installed on 30- degree angles (See site map). The site was granted closure approximately 17 months after the application due to the high degree of accelerated natural attenuation that resulted from the use of HRC at the site.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español