Petroleum Hydrocarbon and Chlorinated Solvent Treatment Using PersulfOx™ at a Former Service Station

Overview

Petroleum hydrocarbons and chlorinated compounds were discovered in groundwater at a former gasoline service station/auto-repair facility. This redevelopment site, located in Bronx County, New York, previously housed an underground storage tank (UST) used for gasoline storage. Following the discovery of groundwater contamination in excess of NYSDEC groundwater protection standards, the UST and soils were removed to bedrock at a depth of 11 feet. Further monitoring revealed toluene and benzene contamination as well as tetrachloroethene (PCE) and trichloroethene (TCE) impacts from parts cleaning associated with the on-site auto-repair shop. Remedial action was required to restore site groundwater and make way for redevelopment and construction of a new building. In Situ chemical oxidation (ISCO) using PersulfOxTM was chosen as the remediation approach.

- PersulfOx is a persulfate based ISCO reagent that promotes rapid and sustained in situ oxidation of a wide-range of organic contaminants.

- This patented technology utilizes a unique catalytic surface on which oxidants and contaminants react in a process known as “surface mediated oxidation.”

- PersulfOx also contains built-in activation which eliminates complex and potentially hazardous chemical addition required to achieve traditional persulfate activation.

- From a health and safety aspect, the use of PersulfOx alone is safer than traditional activation methods such as heat, chelated metals, hydrogen peroxide or base.

- If warranted, PersulfOx can also be activated through traditional means to achieve site remediation goals.

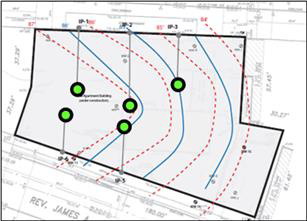

The ISCO treatment system consisted of a series of pipes extending below the basement level of the existing slab for the specific purpose of delivering PersulfOx directly onto the bedrock surface. The pipes terminated into dispersion pits scraped into the bedrock allowing PersulfOx to pool and enter the fractures (Figure 1). The ISCO delivery system design allowed for multiple reagent applications as often as required to complete the remediation process.

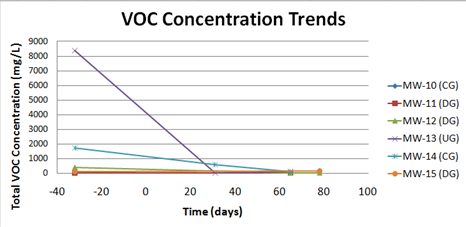

Current trends in the available monitoring well data indicate significant reductions in total VOCs (Figure 2).

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español