Remediation of a Diesel Plume at an Active Rail Facility in Yorkshire, UK

Based on a AquaConSoil 2017 platform presentation by Richard Bewley (AECOM) titled: “Treatment train strategies at operations sites: Incorporation of oxidative or reductive bio-stimulation following physical removal of contamination”.

Summary

Operational sites pose particular challenges for effective remediation due to access restrictions imposed by infrastructure and avoidance of disruption to the day-to-day activities taking place. Under such circumstances, treatment trains may achieve effective contaminant removal though the deployment of sequential approaches that are based on successive physical, chemical and/or biologically-based techniques corresponding to the severity of mass remaining.

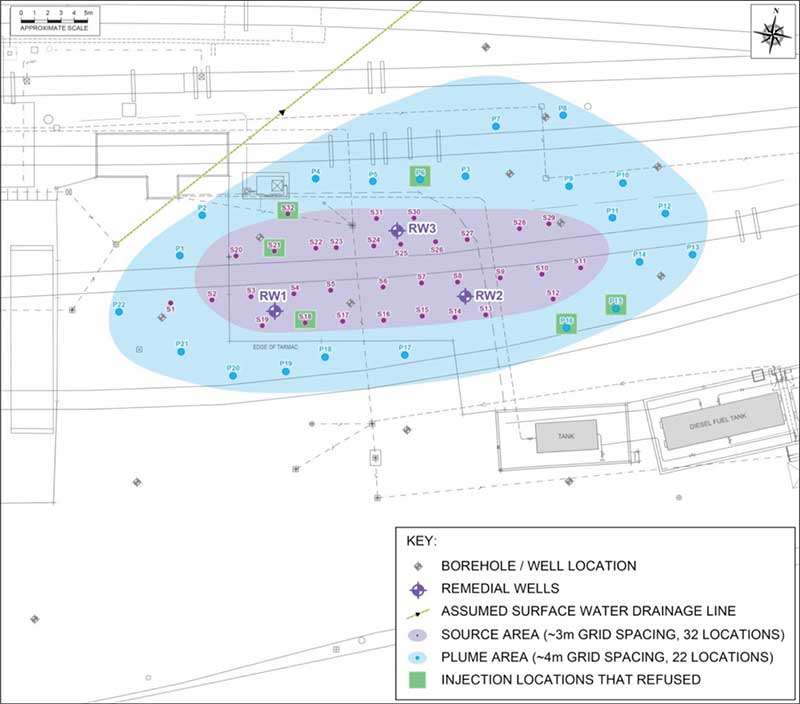

At a rail facility in Yorkshire, a loss of diesel fuel had resulted in several centimetres of free product on the groundwater and dissolved phase plume to have an area in the order of approx. 500m2.

Design and Application

The solution provided by AECOM consisted of a 3-phase treatment train:

- Phase 1: Physical Extraction – During an 18-month period of operation, approximately 10,000 litres of product were recovered using total fluids pumps.

- Phase 2: Enhanced Natural Attenuation (bio-oxidation) – Following attainment of an asymptotic point of recovery, ORC Advanced® was injected by direct push at 48 locations throughout the source and plume areas, to a maximum depth of 3m BGL. The site was monitored quarterly for 12 months following the ORC Advanced injection.

- Phase 3: Monitored Natural Attenuation – The ongoing reduction in TPH through Natural Attenuation was monitored for a further 15 months.

Results

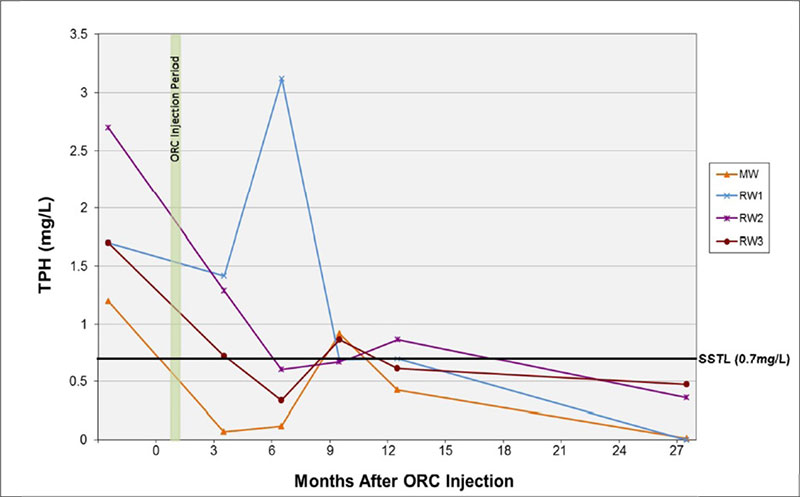

The treatment of the dissolved phase with ORC Advanced resulted in a decrease in concentrations of Total Petroleum Hydrocarbons (TPH) initially ranging from 1,200 – 2,700μg/l to 400 – 900μg/l over approximately 12 months (see Fig. 2).

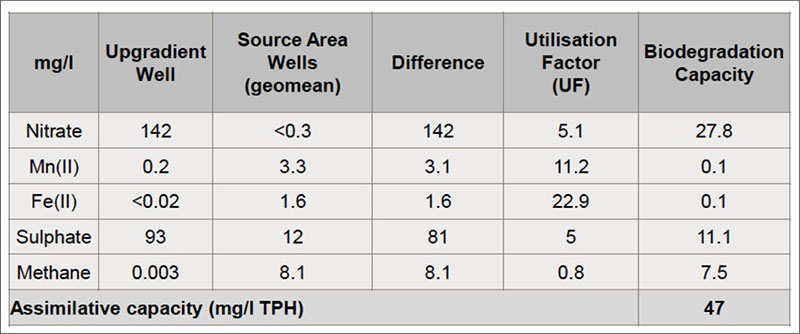

An estimate of assimilative capacity (see Fig. 3) indicated that this was equivalent to 47,000μg/l TPH, which was well in excess of these residual concentrations, and dominated by nitrate.

Fig. 2 TPH reductions over time after ORC Advanced injections

To verify that ongoing natural attenuation was successful, a final monitoring round was undertaken by AECOM after a further 15 months. This indicated TPH concentrations ranged from 500μg/l to below detection, with all wells being below the target of 700μg/l.

Fig. 3 Assimilative capacity estimation

Conclusion

- The use of an integrated treatment approach ensured that the appropriate technology was matched with the contaminant concentrations across the site and throughout the project. This lead to treatment efficiency being maintained throughout the project, minimising cost and time.

- The use of ORC Advanced achieved low groundwater concentrations in a matter of months, allowing a short period of MNA to confirm concentrations were below target.

- The ability of ORC Advanced to be applied by small direct push rigs and then diffuse oxygen beyond the injection location makes it ideal for use on busy operational sites.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español