Integrated remediation allows for redevelopment of historic industrial site

Introduction

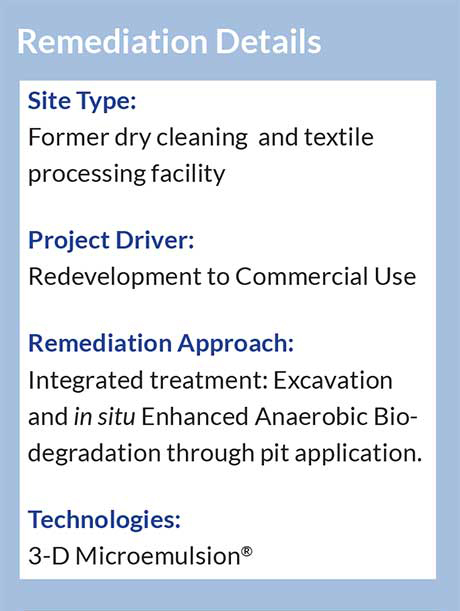

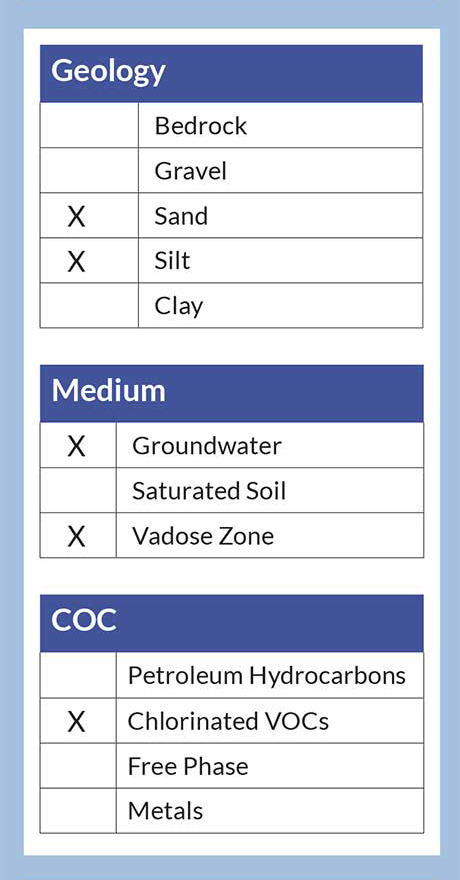

Belgian brownfield developer REVIVE had to remediate a former textile processing and dry cleaning industrial facility. Following demolition of the existing site buildings, hotspots of petroleum hydrocarbons and chlorinated solvents were discovered on the site. The main contaminants of concern were cis-1,2-dichlorethene (DCE) and vinyl chloride (VC) and it was determined that remediation works were required.

Belgian brownfield developer REVIVE had to remediate a former textile processing and dry cleaning industrial facility. Following demolition of the existing site buildings, hotspots of petroleum hydrocarbons and chlorinated solvents were discovered on the site. The main contaminants of concern were cis-1,2-dichlorethene (DCE) and vinyl chloride (VC) and it was determined that remediation works were required.

Original remedial plan and targets

- Remove human health risk by source zone remediation using excavation coupled with hydraulic containment;

- Eliminate off-site migration risk by source zone remediation using excavation coupled with hydraulic containment;

- Transport contaminated soils for ex situ treatment in soil hospital;

- Treatment of impacted groundwater using a Pump and Treat (P&T) system;

- Allow natural attenuation of the residual dissolved phase contamination.

Initial excavation works

An area of approx. 400m2 was excavated to a depth of 6m BGL (approx. 2,300m3) and hydraulically contained. During and after the excavation works, a series of validation samples were taken from the walls of the excavation and inside the pit. The ones taken during the works were used to confirm the contamination source, spread and local variations in geology, which informed the direction of the excavation in progress.

Adjustment of the risk assessment

During these works it became clear that there was too much sorbed contamination which could not be reached by making the excavation deeper, due to the: (1)Technical complexity of the existing excavation, making it unsuitable to enlarge. (2) Need for a larger crane to reach the new depth required. (3) The existing pressured groundwater already being pushed up again the thin clay layer. Any increase in the hydraulic containment would risk the clay giving way to the pressure and burst open. (4) Requirement for extra stability works to keep the excavation safe. As a result, no further excavation was deemed appropriate and instead, the risk-assessment was adjusted to remedial target value (RTV) of 325 μg/L vinyl chloride (VC) in groundwater. REGENESIS was asked to provide a solution for the residual contamination inside the excavation.

In Situ remedial design & application

REGENESIS proposed a pit application of our 3-D Microemulsion® (3DMe) product. 3DMe is an in situ technology designed to provide enhanced anaerobic biodegradation of chlorinated solvents and daughter products, and works by stimulating the reductive dechlorination process. Once applied, 3DMe remains active in the subsurface for an extended period of 5 years from a single application. 980kg of 3DMe was diluted with water before being applied evenly at the bottom of the excavation through a network of 5 specially installed drains embedded in clean sand.

Results

Following application of the 3DMe, the VC concentrations were reduced from approximately 1,600ug/L to below the RTV within 7-10 months. The concentrations continued to decline to very low levels during the rest of the validation period. Small amounts of Cis-1,2-dichloroethene (DCE) were also degraded in the process, with ethene production showing that full reductive dechlorination occurred at the site.

The final monitoring results showed an elevated TOC, low Redox and high ethene, suggesting that ongoing enhanced reductive dechlorination would continue to address the residual dissolved phase contamination beyond the validation period.

Conclusion

- An in situ enhanced reductive dechlorination approach was easily integrated into an existing physical remedial strategy;

- The 3DMe amendment was simple and safe to apply;

- The cost of application of 3DMe was low, yet it allowed the overall remedial strategy to reach low dissolved phase targets;

- The application caused no delay or disruption to the site development, with remediation occurring in the subsurface following backfill of the excavation.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español