Integrated Remediation Approach with Sodium Persulfate based In Situ Chemical Oxidation (PersulfOx®) and Biosparging on Impacted Soils and Groundwater

Introduction

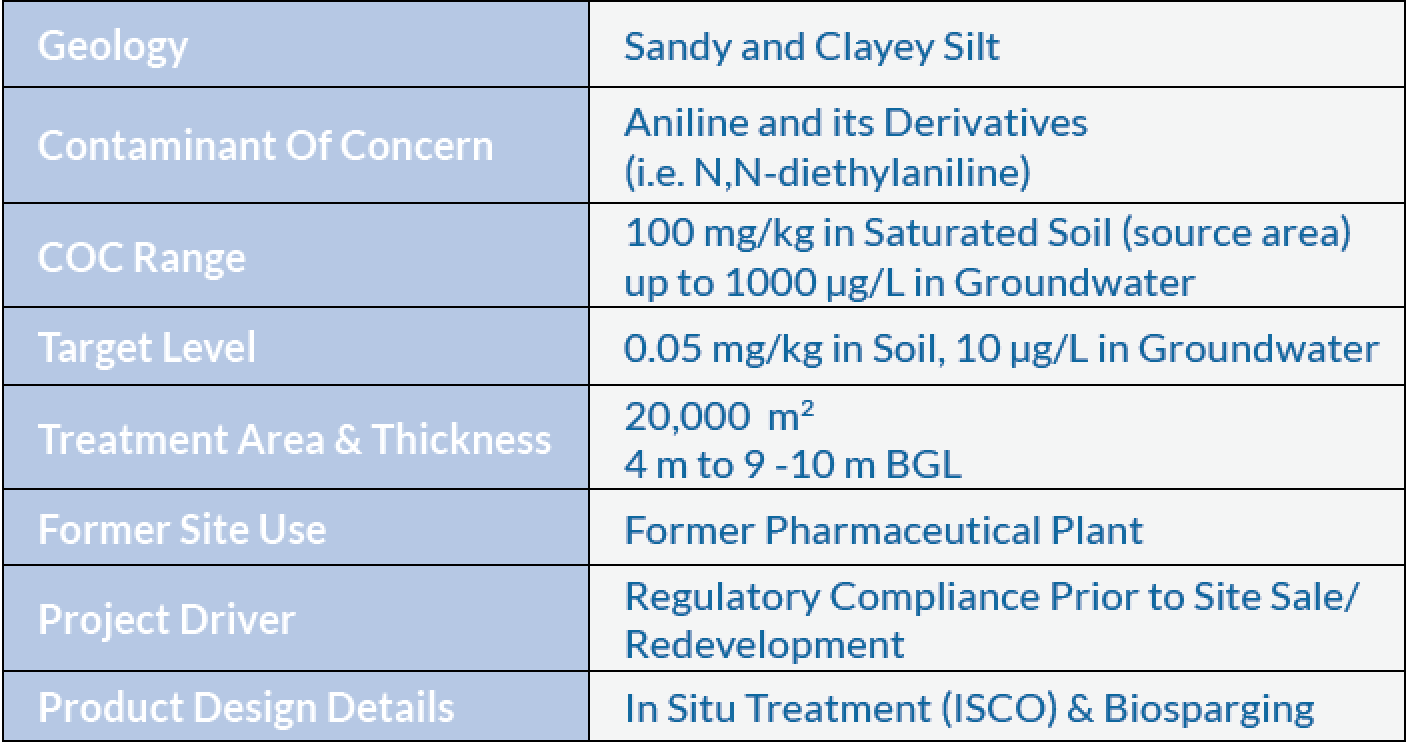

The soil and groundwater under a disused pharmaceutical plant in the North of Italy had become impacted with a mixture of aniline and its derivatives, due to historic spillages and leaks on the site. The contaminated unsaturated soil had been removed previously by excavation and disposal (approx. 1,000-1,500 m2) to a depth of 5 m BGL. However, some contamination had infiltrated through the vadose zone and impacted the groundwater, resulting in a 100-meter long plume. In the source area, residual contamination adsorbed to the saturated soil had been detected at 6-9 m BGL; below the maximum depth of the excavation previously completed. It was observed that during periods of high precipitation, the groundwater level would rise and promote recurrent desorption events from this contaminant mass into the groundwater.

Copernico S.r.l was engaged to delineate the contamination through additional site investigation using Membrane Interface Probe (MIP). They found that the main contaminant of concern (COC) was N,N-diethylaniline, which was present at concentrations of approx. 100 mg/kg in saturated soil in the source area, and up to 1,000 μg/L in groundwater across the whole of the site.

Fig. 1 Installation of injection points

Remediation Strategy

A laboratory study previously performed on material and contaminants from this site had shown that aniline was biodegradable under aerobic conditions (especially N,N-diethylaniline). Following this, a biosparge pilot scale study was completed, which proved unsuccessful at dealing with the high concentrations and contaminant loading in the source area. Copernico therefore determined that an integrated remediation approach would be required; initially using ISCO to rapidly address the higher concentrations and then enhanced biological degradation to treat the residual dissolved phase contamination.

It was determined that a persulphate-based ISCO agent was to be applied in two injection campaigns to treat the high levels of adsorbed contamination. After this, the biosparging system would then be operated both in the source and in the plume area. At the downstream boundary of the site, an ongoing pump & treat (P&T) system was used to provide hydraulic containment of the plume within the property, in line with regulatory requirements.

For the ISCO phase, Copernico selected PersulfOx®, a sodium persulfate oxidant with a patented catalyst already mixed into the product. Therefore, no hazardous activation products are required, making the treatment process much safer. The application volume is therefore also reduced, providing cost and time savings to the project.

PersulfOx promotes rapid and sustained ISCO of a wide range of organic oxidants including aniline, through both alkaline activation and surface mediated oxidation on the catalytic surface. This makes the treatment more efficient and effective compared to traditionally based persulfate based ISCO.

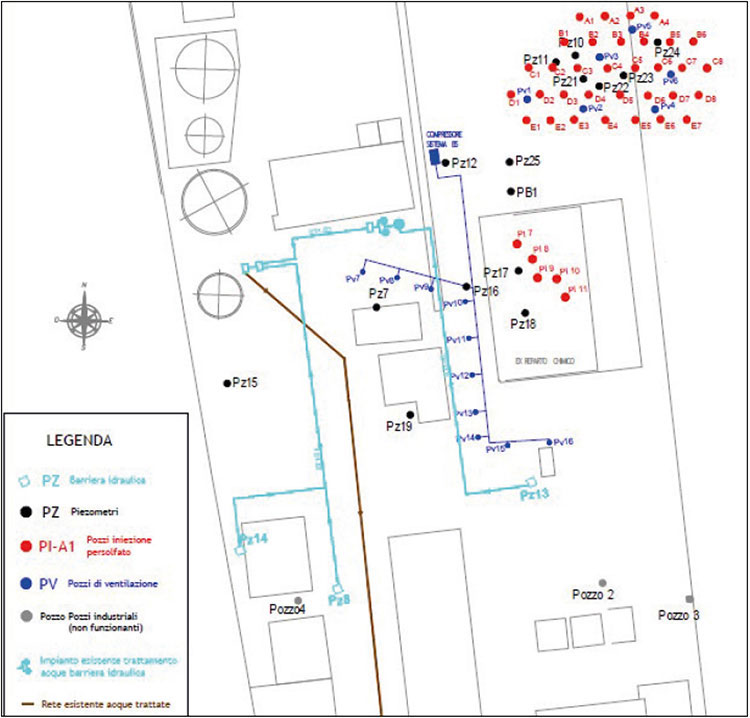

Fig.2 Map showing the PersulfOx injection points (red), Biosparging wells (blue), P&T system (light blue), monitoring wells (dark)

PersulfOx Injection Works

Within the target area 33 injection points (A1-E7), were installed within the vicinity of monitoring wells Pz11, Pz17, Pz18, Pz22, Pz23 and Pz24 (Fig.2).

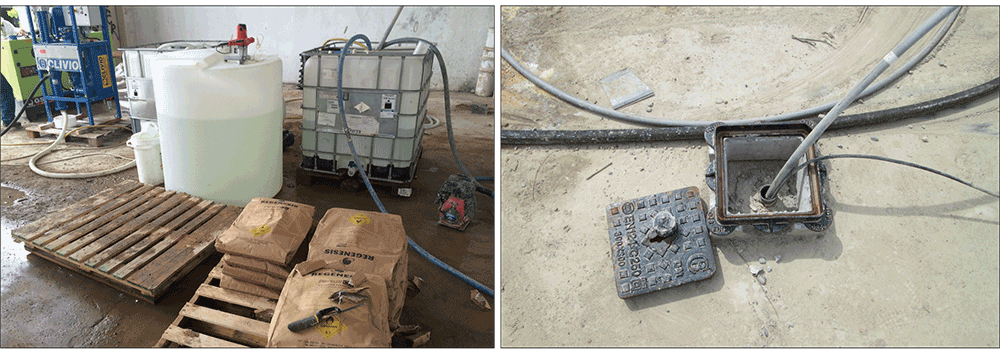

7,000 kg of PersulfOx was mixed with water to a 15-20% dilution prior to injection into the source area. PersulfOx is simply added to water and agitated, with no requirement for hazardous activation chemicals (such as caustic soda or hydrogen peroxide), making the process much safer, quicker and requiring a lower injection volume (see fig. 3 and 4).

PersulfOx was applied into the injection wells between 6 and 9 m BGL.

A special well completion was used that allowed the application to be completed in 500 mm vertical intervals, in order to ensure an even vertical distribution of the PersulfOx application (fig. 5 and 6). A dose of 25 kg PersulfOx to 175 L of water was applied within each section at approximately 5 Bar or less. A manifold system was used that allowed application into several wells at once in order to make the injection more efficient. The works were completed in 20 days.

Following the initial ISCO application to reduce the contaminant loading in the soils and groundwater in the source area, the biosparge system was operated to provide enhanced natural attenuation of the residual dissolved phase contamination. The biosparge system consisted of 5 ventilation points in the secondary source area, and a second line of 10 points in the plume area; all ventilation points are 15 meters deep.

Fig.3 and 4 Mixing activities

Fig. 5 and 6 Injection setup and multi-valve injection points

Results

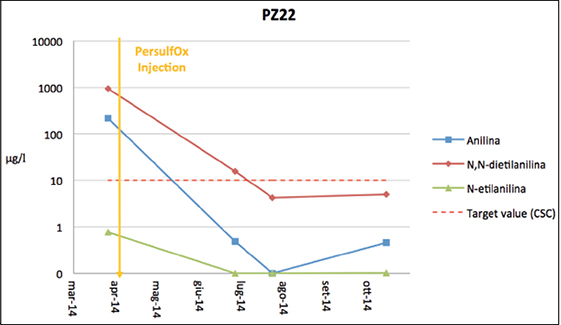

The first PersulfOx injection campaign was carried out during the months of May and June 2014. Monitoring results from October 2014 show significant, rapid and sustained reduction in all of the Contaminants of Concern (COCs) and remedial targets have been achieved for;

- Aniline (12 out of 12 wells in treatment area)

- N,N-diethylaniline (10 out of 12 wells in the treatment area)

- N-ethylaniline (11 out of 12 wells in treatment area)

The efficacy of the remediation has been monitored through a network of 20 monitoring wells across the site (20,000 m2). Periodical monitoring campaigns have been carried out, including chemical-physical field parameters and laboratory analysis.

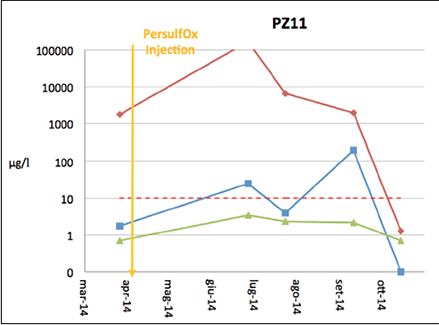

Immediately following injection, a temporary increase in the groundwater concentrations of the aniline(s) was observed. This was due to desorption of part of the soil contamination due to the disturbance of the injection and the effect of the ISCO treatment. Once the contamination was in the groundwater, it was rapidly oxidised and the concentrations were then seen to reduce rapidly.

An example of this is well Pz11 (located in one of the most highly impacted areas (7,000 μg/L)), see Figure 7, producing a significant contaminant mass reduction of the whole system (sorbed and aqueaous phase), with a 99% reduction in dissolved phase concentrations by October 2014.

ISCO using PersulfOx not only provided contaminant mass reduction from both the soils and groundwater. Partial chemical oxidation of the COCs resulted in the contaminants becoming more bioavailable and biodegradable. This increased the efficacy of the biosparging system on the residual dissolved phase contamination.

Fig. 7 Total COC concentrations decreased below the target values in Pz11 and Pz22 (Shallow portion of the aquifer) with the use of PersulfOx in 6 months after application.

In the PersulfOx treatment area, all monitoring wells met the target goals within six months for all COCs except for two deep wells (Pz10 and PB1) that still show concentrations marginally higher than target. It is thought that these wells represent areas with higher contaminant mass than was anticipated. Subject to further groundwater monitoring results, a second PersulfOx application may be completed at the site, targeting the recalcitrant wells, as foreseen in the remediation plan. This treatment will be smaller than the first, accurately targeting source areas with higher total contaminant mass.

Biosparging will then be continued in these areas to enhance the biological degradation of the residual dissolved phase contamination. Downgradient of the biosparging system a significant decrease in groundwater aniline concentration has been observed reducing from 1,000 μg/L to <0.1 μg/L. After the remediation activities, aniline concentrations have not exceeded targets (10 μg/L) at the boundary pumping wells, despite periods of heavy rainfall. The remediation resulted in a significant reduction of contaminant mass across the treatment area for all COCs and the residual concentrations are expected to decline further over time.

Conclusions

An intelligent, staged approach was used to complete the site investigation and development of an integrated remediation strategy for the site. This comprised accurate contaminant delineation using Membrane Interface Probe (M.I.P.), evaluation of potential remedial strategy and verification of localised geological and geochemical conditions across the site. This resulted in an accurate in situ remedial design, integrating rapid mass reduction of the COCs

and enhanced biological degradation of the residual dissolved phase contamination.

The treatment successfully reduced COC concentrations to below target goals in the majority of the treatment area and continued to reduce the contaminant levels throughout the validation period.

This site is an excellent example of how good site investigation and an integrated treatment design strategy can provide cost effective and assured remediation of problematic contaminants.

About the Product

PersulfOx is an advanced in situ chemical oxidation (ISCO) reagent rapidly destroys a wide range of contaminants such as petroleum hydrocarbons and chlorinated solvents through abiotic chemical oxidation reactions.

It is an all-in-one product with a built-in catalyst which activates the sodium persulfate component and generates contaminant-destroying free radicals without the costly and potentially hazardous addition of a separate activator. The patented catalyst enhances the oxidative destruction of both petroleum hydrocarbons and chlorinated contaminants in the subsurface.

Benefits

- Promotes rapid and sustained in situ oxidation of a wide range of organic contaminants

- Contains a built-in catalyst that remains active through the entire lifespan of the persulfate oxidation reaction

- The catalyst also eliminates the need for the co-application of alternate and potentially hazardous activation chemistries

- Contaminant oxidation performance equivalent to best alternative persulfate activation methods

- Fewer health and safety concerns than with use of traditional activation methods such as heat, chelated metals, hydrogen peroxide or base

- Single component product results in simplified logistics and application

- No additional containers or multi-step mixing ratios required prior to application

- Compatible with combined remedy approaches including enhanced

biodegradation

PersulfOx Intellectual Property

With the purchase and proper use of PersulfOx Catalyzed Persulfate, Regenesis’ customers gain the benefits of the latest advancements in persulfate technology for environmental remediation.

Furthermore, through an arrangement between Regenesis and FMC Corporation, PersulfOx customers are free to use PersulfOx without any risk of patent infringement claims from FMC Corporation.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español