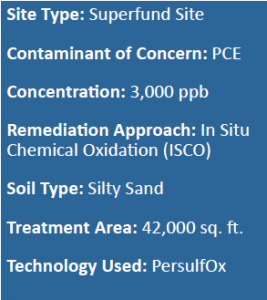

Turn-Key PCE Plume Remediation on at Michigan Superfund Site

Former Manufacturing Facility Treated with 437,000 Pounds of PersulfOx® in 18 Days

Project Highlights

- PersulfOx was selected over other persulfate activation methods because of its inherent health and safety benefits and easy-of-use.

- An aggressive application schedule was implemented to satisfy stakeholders – 37,800 lbs (15,500 gallons) of PersulfOx were injected in a single day.

- On-site diagnostics conducted by RRS confirmed PersulfOx distribution throughout the targeted treatment area.

- The project was completed ahead of schedule and on budget.

- The site was left with minimal impact to the PGA Championship Golf Course.

Project Summary

A former manufacturing facility in Western Michigan was redeveloped into an active golf course. The USEPA took over responsibility for cleanup of the chlorinated solvents that remained. Regenesis Remediation Services (RRS) was contracted by a leading consulting fi rm to implement a remediation design to address the chlorinated VOC plume with concentrations as high as 3,000 ppb. PersulfOx was selected over other persulfate activation methods such as hydrogen peroxide or alkaline activate on because the built-in catalyst minimized hazardous materials handling allowing for a safer and easier application. This was especially important because of the treatment areas close proximity to a sensitive receptor (river). Despite persistent freezing temperatures, RRS was able to finish this project ahead of the projected schedule. The RRS team faced a unique challenge on this site as it is a PGA Championship Golf Course which required extreme caution while injecting on the course. Strategic injection point placement, equipment staging, and surface protection via mats were just a few of the techniques implemented by the team

Remediation Approach

The 18-day injection event included 437,000 pounds of PersulfOx which was applied through 129 injection points in a grid pattern 5-30 feet below ground surface. The team used two direct-push injection machines to apply PersulfOx into eight points injection simultaneously.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate componentand generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español