Types of Permeable Reactive Barriers

Permeable Reactive Barriers

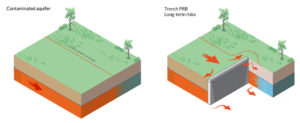

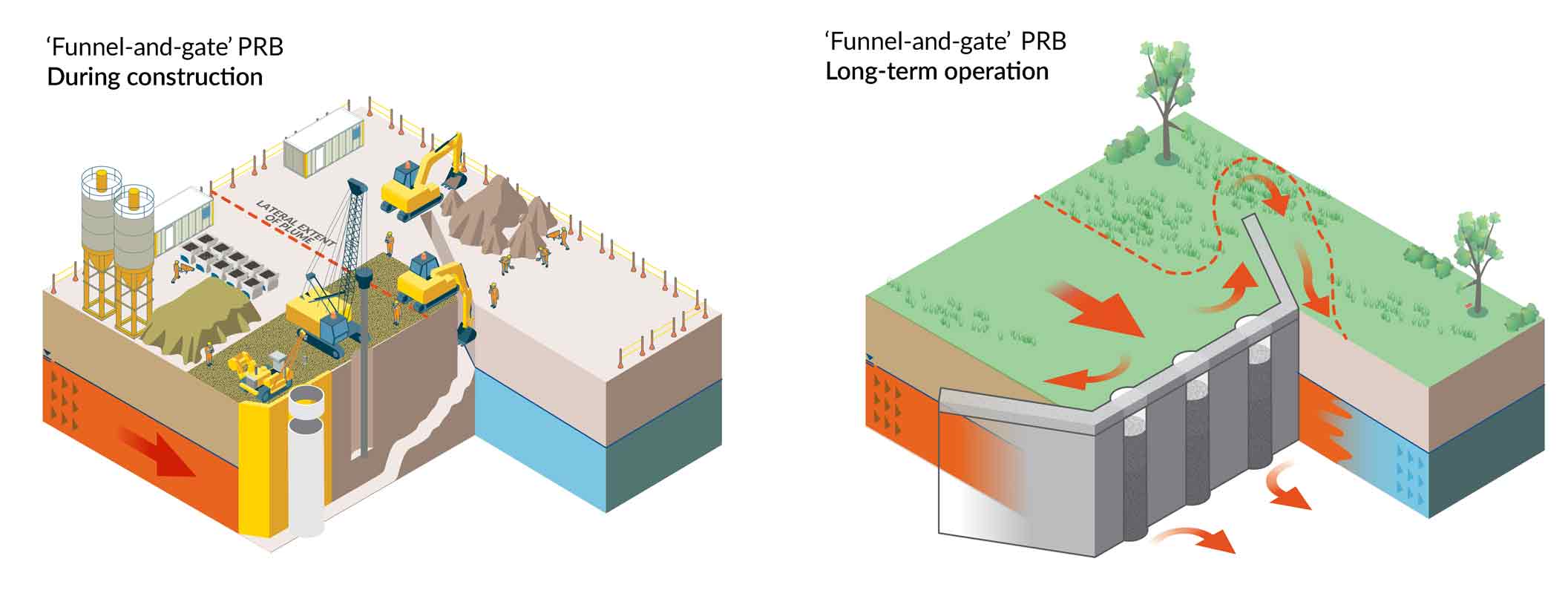

A Permeable Reactive Barriers (PRB) is made by creating a subsurface permeable reactive cell that intersects groundwater flow. The PRB prevents any further migration of pollution in the groundwater by reacting with it through sorption, biological degradation or other processes. Typical installations include:

- Mixing reactive media with soils using augers, soil mixing and piling rigs

- Replacing existing soils with granular fill mixed with reactive media through trenching

- Installation of replaceable reactive media filters/cartridges – Normally installed as a funnel-and-gate system using sheet pile or cement slurry walls

Disadvantages of physical barriers

- Expensive to install

- Large footprint, affecting site work and even the final construction design

- Significant time and cost in a site redevelopment programme

- Can present geotechnical challenges to construction

PRBs are also subject to clogging due to an influx of fines, or when the media is spent. This results in contaminated groundwater backing-up behind and eventually by-passing the PRB.

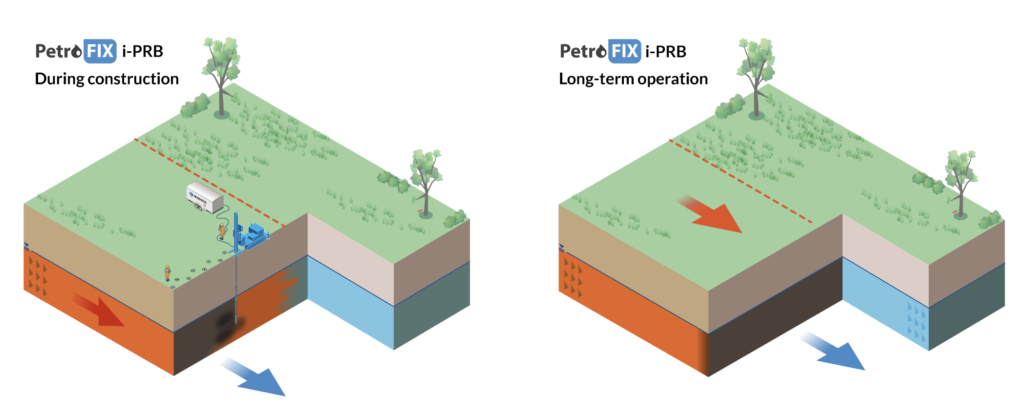

PetroFix Injectable PRB

A PetroFix Injectable Permeable Reactive Barrier (i-PRB) provides both rapid and long-term treatment from a single, simple installation. This form of PRB is created through the injection of PetroFix colloidal activated carbon and electron acceptor liquid, into the subsurface.

PetroFix coats the impacted aquifer creating a subsurface purifying filter. This removes the advecting contamination through sorption. Enhanced biological degradation, stimulated by the nutrients within PetroFix, destroy the adsorbed contaminants, freeing up sorption sites to filter out further contaminant influx.

Advantages

- Low cost

- Safe

- Simple to apply

- Less effect on build programme – can be completed rapidly, concurrent to other enabling works

- Low disturbance – small footprint equipment and few personnel required

- No large machinery needed

- No piling mat

- No excavation

- No offsite disposal

- No effect on construction footprint

Example Scenario:

Disadvantages of PRBs:

Advantages of an injected PRB:

Project Example:

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español