Cost-Effective Treatment of Hexavalent Chromium and Chlorinated Solvents

Summary

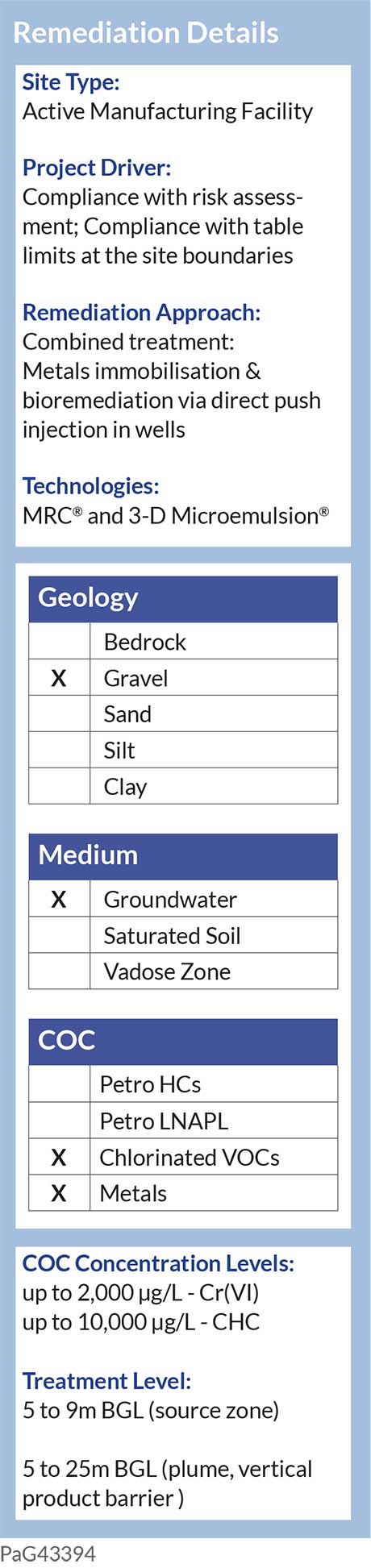

Historic leakages at an active manufacturing facility in Northern Italy resulted in the underlying groundwater becoming impacted with hexavalent chromium (Cr(VI)) contamination of up to 2,000 μg/L, and chlorinated solvents (CHC) concentrations of up to 10,000 μg/L. 3-D Microemulsion® (3DMe) and Metals Remediation Compound (MRC®) were selected to remediate the site because of:

- The combination of products allow for effective distribution and treatment within a highly heterogeneous and deep aquifer comprising gravels and boulders;

- Minimal disturbance caused by in situ remediation activities and the ability to inject indoors, on this tight and busy site.

1m 36s reading time

Design and Application

The site was split into a number of zones, which have been treated in phases. For the source zone, 3DMe and MRC were injected into 16 wells on a 3m x 3m grid, providing a targeted treatment of the most impacted part of the site at a depth of 5 to 9 mBGL.

The plume was then addressed through the use of a 3DMe and MRC barrier, which stopped the migration of the contaminant plume offsite, without affecting the groundwater ow itself. The application was completed through 8 xed, multi-level wells installed from 5 to 25mBGL. Since this injection, further areas of the site have become accessible and future applications are planned.

What’s Special?

- MRC provides rapid and sustained immobilisation of Cr(VI) by reducing the soluble hexavalent chromium into solid, non-hazardous trivalent chromium, which settles out of the groundwater.

- 3DMe’s unique self-distribution mechanism allowed effective wide area treatment of both CHC’s and Cr(VI) with limited access onsite.

- The remedial works included treatment inside an historic building

- Remediation works were carried out with minimal disruption to ongoing industrial activities and no equipment was left on site in between the first two injection phases.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español