Successful standalone treatment of a large plume with difficult site conditions

Introduction

The process of Enhanced Reductive Dechlorination (ERD) for the biological degradation of chlorinated compounds, is now a widely used and proven in situ remediation approach. Nevertheless, ERD is often used only as a ‘polishing step’ of the plume, rather than a stand-alone primary remediation technology.

2m 57s reading time

In our experience, the potential of ERD is much more powerful than a final stage to address residual dissolved phase contamination. In many cases, it is the only viable remediation option available when site conditions are difficult, as was the case at this an active industrial site located at an airport in the Southwest of France.

Challenging Site Conditions

- Restricted access; the contamination was located on the sites of 2 different companies active in the aviation industry (manufacturing airplane parts).

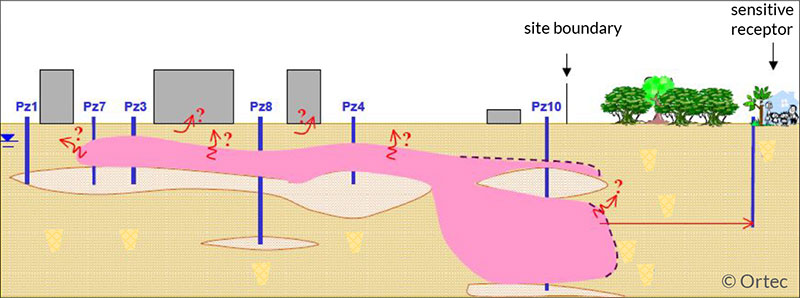

- Wide contaminant distribution; the contamination spread along the permeable bedding of a sewage system located in the gravelly clay. From here, the contamination seeped into the sandy gravel layer. This resulted in a very long plume with the potential to cross the site border approx. 700 m downgradient of the source (see section below).

- Heterogeneous geology with very different permeabilities; gravelly clay overlying sandy gravel.

Seasonal fluctuations in the groundwater table. - There was a wide range in contaminant concentrations on this site; Relatively high PCE concentrations in the source area (up to 14,000 μg/l), with very low dissolved phase concentrations further away from the sewage system.

Remediation Method/Application

After a successful pilot test, full-scale application using a single injection of REGENESIS’ controlled-release electron donor 3-D Microemulsion (3DMe) into 70 injection points. ‘Top-down’ direct-push injections were used to provide a targeted vertical distribution of the electron donor.

The injection work was carried out in 3 weeks total, spread over 2 campaigns:

- The injection points in the source zone were located among buildings with ongoing activity. These injections were carried out during the summer holiday period, to minimise disturbance of commercial activity.

- A downgradient product barrier was installed in spring.

Full Scale Results

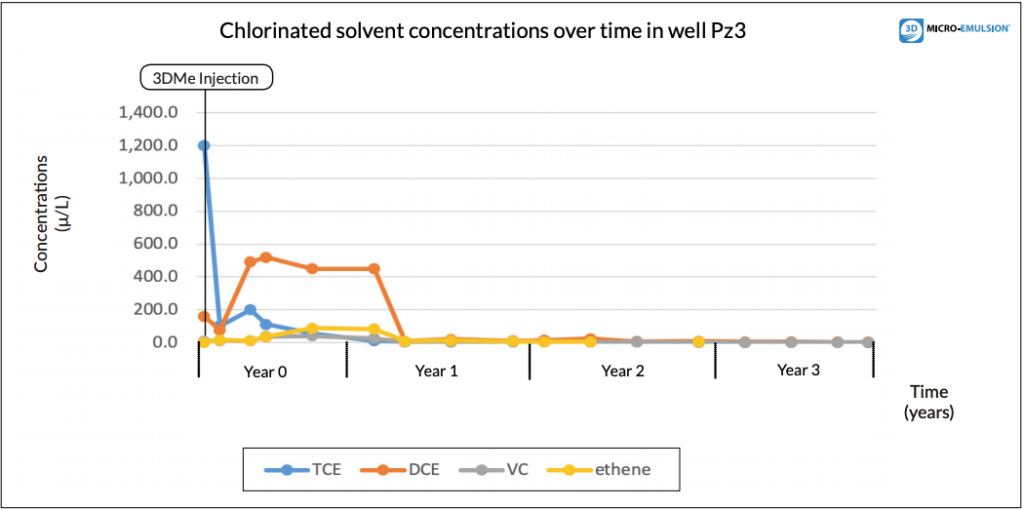

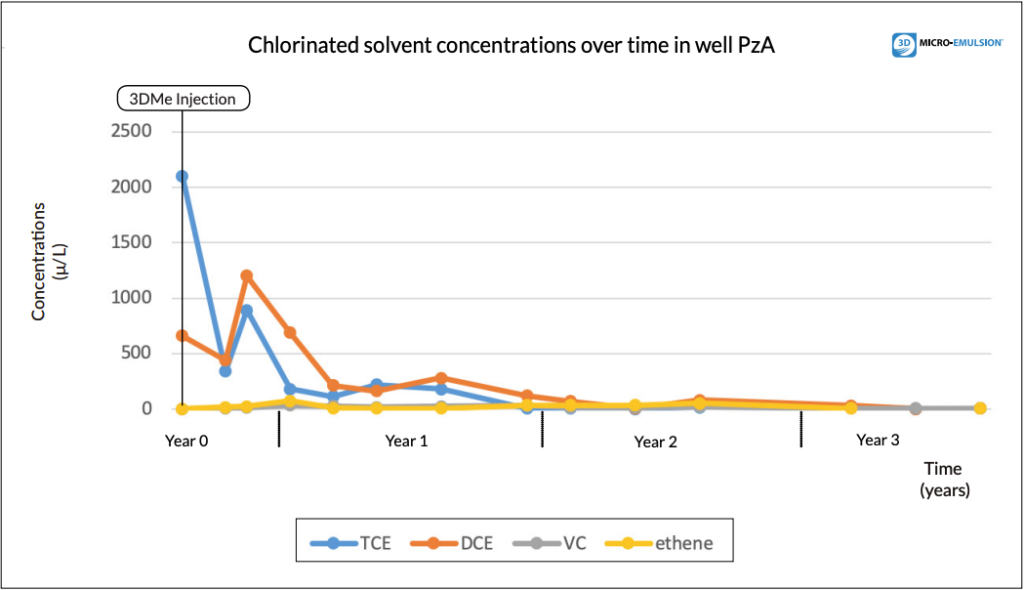

An excellent reduction of the parent compound TCE in the source zone can be observed: for example the area around Pz3 and PzA. The graphs show the sequential formation and degradation of the daughter products DCE and VC, which then decrease showing that full reductive dechlorination is occurring.

Conclusions

- With a longevity of minimum 4 – 5 years, 3DMe was selected to remediate the site from a single application;

- This removes the requirement for further application on this busy factory site:

- This allows the contamination within the overlying clay layer to be addressed, avoiding a rebound due to back-diffusion.

- The ability of 3DMe to self-distribute over a wide radius of influence from each injection location, allowed the number of points to be minimised. This reduced the cost and onsite programme for the treatment.

- The treatment has clearly achieved mass reduction of the contamination. This has reduced the risk to the site and offsite receptors.

- The treatment is ongoing, targeting the residual contamination in the overlying clay and avoiding rebound in concentrations

- Ideal conditions for ERD were rapidly created and have been maintained since through the controlled release of electron donor over a wide area. This has lead to full reductive dechlorination occurring, ensuring that all chlorinated parent and daughter compounds are degraded.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español