Rapid TPH and BTEX treatment using enhanced desorption and extraction

Introduction

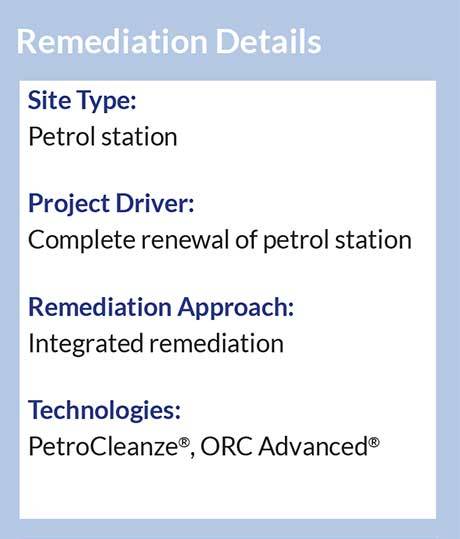

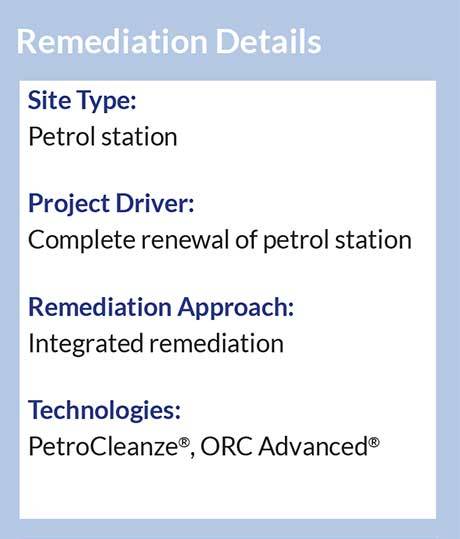

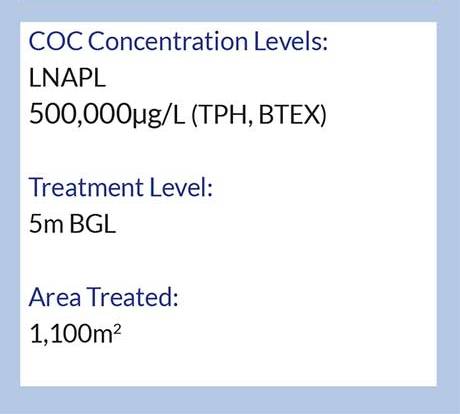

A large petrol station located along one of the busiest motorways in northern Italy was undergoing extensive reconstruction, including the demolition of existing buildings, removal of above- and below-ground structures; as well as remediation. The existing underground fuel tanks (USTs) were removed and the contaminated soil surrounding the USTs was excavated to a depth of 5m BGL.

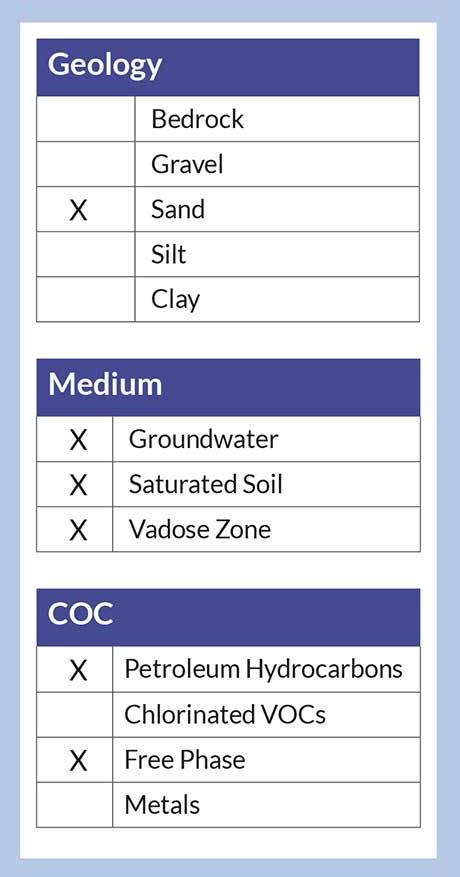

The geology consists of a highly permeable soil comprising sand and gravel to approx. 40m BGL. The average groundwater level is at approximately 4m to 6m BGL, where an extensive contaminant smear zone was observed.

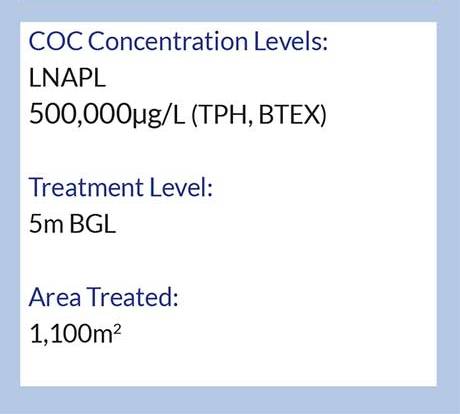

The main excavation was approx. 1,100m2 and 5m deep, with the extent and depth limited by the proximity of the motorway (as well as the presence of groundwater).

The soil at the bottom of the excavation was highly impacted with Total Petroleum Hydrocarbons (TPHs) and BTEX compounds, with concentrations of up to 10,000mg/kg. The groundwater inside the excavation was highly contaminated, with evidence of Light Non Aqueous Phase Liquid (LNAPL) and average concentrations in the range of 500,000μg/L.

Design Approach & Planning

For any treatment approach on this site, to be effective in improving the groundwater quality, it would have to be able to address this secondary source in addition to treating the residual dissolved contamination. The remedial approach also needed to be rapid and effective, in order to allow for immediate back filling. This was because a delay in the construction program would result in a loss of income if the petrol station was not opened on time.

For any treatment approach on this site, to be effective in improving the groundwater quality, it would have to be able to address this secondary source in addition to treating the residual dissolved contamination. The remedial approach also needed to be rapid and effective, in order to allow for immediate back filling. This was because a delay in the construction program would result in a loss of income if the petrol station was not opened on time.

REGENESIS and the Environmental Consultant created an intelligent treatment strategy that took these challenges on board. The remediation approach comprised:

Phase I: Removal of the main contaminant mass present in the saturated soil. This was achieved via Enhanced Chemical Desorption using PetroCleanze, followed by physical abstraction using a vacuum tanker;

Phase II: In Situ biodegradation of the residual dissolved contamination over a period of 9 to 12 months following back fill, via Enhanced Aerobic Biodegradation using ORC Advanced.

PetroCleanze has been developed by REGENESIS to enhance the desorption of contaminants from soil, so that these can be recovered by physical treatment systems. It provides a cost-effective solution for the in-situ treatment of saturated contamination and smear zones. This allows physical treatment systems to be more effective over a shorter period of time, lowering asymptotes and reducing rebound due to ongoing desorption from the smear zone.

PetroCleanze has been developed by REGENESIS to enhance the desorption of contaminants from soil, so that these can be recovered by physical treatment systems. It provides a cost-effective solution for the in-situ treatment of saturated contamination and smear zones. This allows physical treatment systems to be more effective over a shorter period of time, lowering asymptotes and reducing rebound due to ongoing desorption from the smear zone.

When applied in excavation areas, application is quick and desorbed contaminants can be recovered really easily. Usually two to three application and abstraction rounds are required to remove the bulk of the contamination. PetroCleanze is an inorganic technology and therefore avoids introducing a large oxygen demand (as occurs with using surfactants) and promotes enhanced biological degradation of the residual contamination.

PetroCleanze has been developed by REGENESIS to enhance the desorption of contaminants from soil, so that these can be recovered by physical treatment systems. It provides a cost-effective solution for the in-situ treatment of saturated contamination and smear zones. This allows physical treatment systems to be more effective over a shorter period of time, lowering asymptotes and reducing rebound due to ongoing desorption from the smear zone.

PetroCleanze has been developed by REGENESIS to enhance the desorption of contaminants from soil, so that these can be recovered by physical treatment systems. It provides a cost-effective solution for the in-situ treatment of saturated contamination and smear zones. This allows physical treatment systems to be more effective over a shorter period of time, lowering asymptotes and reducing rebound due to ongoing desorption from the smear zone.

When applied in excavation areas, application is quick and desorbed contaminants can be recovered really easily. Usually two to three application and abstraction rounds are required to remove the bulk of the contamination. PetroCleanze is an inorganic technology and therefore avoids introducing a large oxygen demand (as occurs with using surfactants) and promotes enhanced biological degradation of the residual contamination.

Phase I – Enhanced Desorption and Extraction

- Before application, the excavation was divided in seven segments, leaving some pathways for excavator passage. For each segment, a specific PetroCleanze application dose was defined.

- PetroCleanze was applied in each sub-area through the dig and mixed directly with the remaining impacted soil. Due to the high contaminant mass present in some of the areas, LNAPL appeared on the water in less than one hour after the first application (the photos shown overleaf were taken 30 minutes after application).

- The LNAPL was subsequently removed by selective pumping using a vacuum tanker.

- Repeated soil mixing and desorbed LNAPL removal took place over the following days across the whole area (for a maximum of 3 cycles in the most contaminated areas).

- The repeated soil-mixing allowed for ongoing desorption and removal of the contamination without the need to add more PetroCleanze. This process was continued for all the sub-areas until no more recoverable free phase was present.

- Finally, a short period of de-watering was completed to remove part of the residual dissolved phase contamination, with water samples taken before and after.

Phase II – Enhanced Aerobic Natural Attenuation

Following the initial excavation and enhanced desorption treatment, an ORC Advanced application was completed. This targeted the residual dissolved phase contamination. The ORC Advanced provided a controlled release of dissolved oxygen in order to stimulate and maintain enhanced aerobic biological degradation of the groundwater contamination for 9-12 months from the single application. This meant that the excavation could be immediately back filled and the construction continued. The remediation of the dissolved phase contamination therefore continued in situ, with no further operational costs and no disruption to the build programme.

To optimise the application process onsite, a pelletised version of ORC Advanced was chosen. This is because they can be applied directly in the excavation without the need for pre-mixing with water. The Pellets also minimise dust formation during application. The pit application was cost-effective, as it did not require additional equipment to be used on site and the application and mixing was safe, quick and straightforward.

Results

- The remediation activities were completed in approximately 40 days on site, which included the product applications, soil mixing, selective pumping and final pump and treat.

- During this period, more than 400L of petroleum hydrocarbon LNAPL was successfully recovered, as well as approx. 100m3 of highly contaminated groundwater with TPH concentrations in the 100,000-1,000,000μg/L range.

- In addition, 280m3 of contaminated groundwater was removed during the final pump and treat activity (before the ORC Advanced application).

- During desorption and removal, no increase in dissolved phase concentrations was seen in the wells immediately downgradient of the excavation, or on the site boundary. This showed that all desorbed contaminants were successfully extracted during the treatment process.

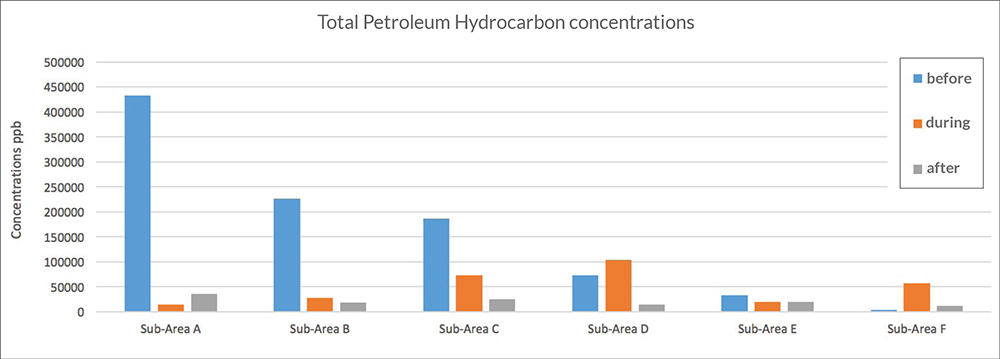

- Subsequent groundwater monitoring shows a significant decrease in concentrations, avoiding any potential delay to the construction programme. The figure below shows the petroleum hydrocarbon concentrations for each sub-area at baseline (blue), during treatment (orange) and after pump and treat (grey).

Conclusion

- The site was remediated on time without disruption to the construction program through the use of enhanced desorption and removal, followed by in situ enhanced aerobic biological degradation.

- An integrated remedial approach was created to target each contaminant type/phase, through excavation of impacted soils, enhanced desorption and extraction of LNAPL and high levels of TPH in the groundwater contamination, to biological degradation of the residual dissolved phase contamination.

- Treatment was limited to the target area with the remediation works producing no increase in downgradient contaminant concentrations.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español