Remediation Allows for Redevelopment at Historic Ohio Brownfield

Project Highlights

- Ohio VAP Certified Professional specified ORC® Advanced Pellets in Remedial Action Plan for purpose of obtaining grant through the Clean Ohio Revitalization Fund (CORF).

- $1.98 million in brownfield’s funding was granted through CORF as a result of Proposed Remedial Action Plan.

- Approximately 18,000 pounds of ORC® Advanced Pellets were applied to the base of 5 former underground storage tank excavation sites to address residual TPH and PAH impacts in groundwater

Project Summary

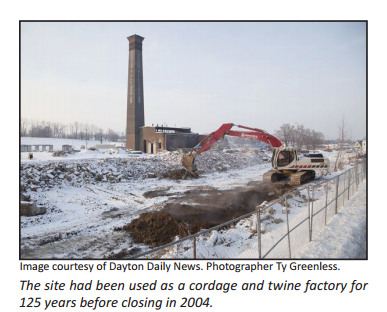

The site, a former cordage and twine factory in Ohio, was closed in 2004 after 125 years of operation. The city and developer secured $1.98 million in brownfield’s funding through the Clean Ohio Revitalization Fund (CORF). These funds were secured for demolition and remediation activities at the site included but not limited to asbestos removal, underground storage tank removal, and contaminated soil excavation and demolition activities.

Remediation Approach

Approximately 18,000 pounds of ORC Advanced Pellets were specified by the Ohio VAP Certified Professional responsible for this project. Per the CORF remedial plan the pellets were applied to the base of 5 former underground storage tankexcavation sites. As part of this combined remedy approach (excavation + biodegradation), ORC Advanced Pellets were included to promote enhanced aerobic biodegradation of residual TPH and PAH impacts in water for a period of 9-12 months.

Technology Description

ORC Advanced® Pellets (ORC-A Pellets) are a pelletized version of REGENESIS’ widely-used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications. ORC Advanced Pellets are approximately 3-10 mm in size.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español