Extensive Tert-Butyl Alcohol (TBA) Contamination Treated with Combined Remedies

Project Summary

Site operations at this manufacturing facility located in New Jersey caused groundwater to be impacted with tert-butyl alcohol (TBA). Previous attempts at site remediation using alkaline activated persulfate had not met performance goals. PersulfOx was subsequently applied in an area of significant TBA contamination resulting in orders of magnitude reductions within just three weeks’ time.

Alkaline Activated Persulfate – Unsuccessful

An initial attempt at remediation using alkaline activated persulfate included a full-scale injection of persulfate and sodium hydroxide (NaOH). This approach was deemed unsuccessful, as sampling after one week showed pH to be below the range required for persulfate activation, leaving significant untreated TBA in site groundwater. Additionally, the large volume of NaOH required for this approach raised concerns of impacting nearby storm sewers.

Remediation Approach

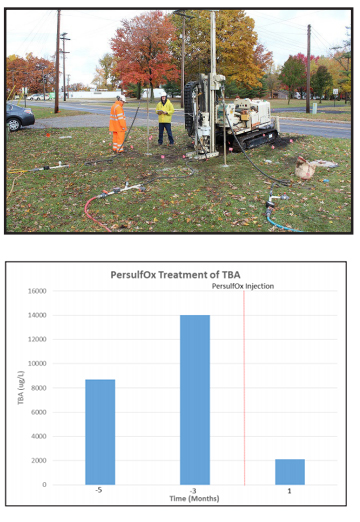

The treatment approach included a grid of six injection points placed 15-feet apart into the sandy aquifer. Each point received >1,800 pounds of PersulfOx across of 5-foot thickness.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant destroying free radicals without the need for the addition of a separate activator.

Results

Following the PersulfOx application, site monitoring indicated a significant reduction in TBA contamination in the target zone. TBA concentrations were reduced from >14,000 ug/L to 2,100 ug/L with a single injection of PersulfOx in only three weeks’ time.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español