Augmented Pump and Treat, ISCO and ENA completed under rail lines

Summary

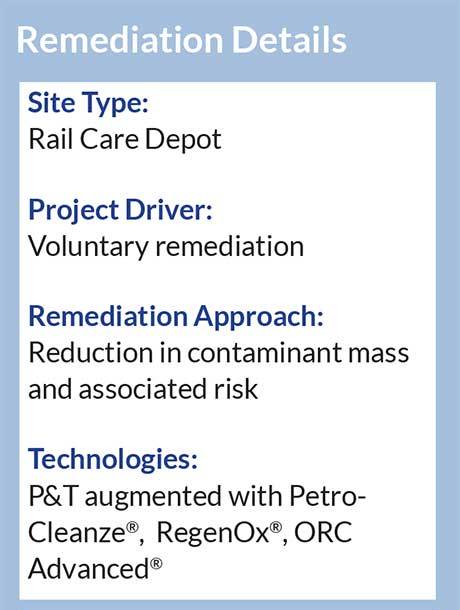

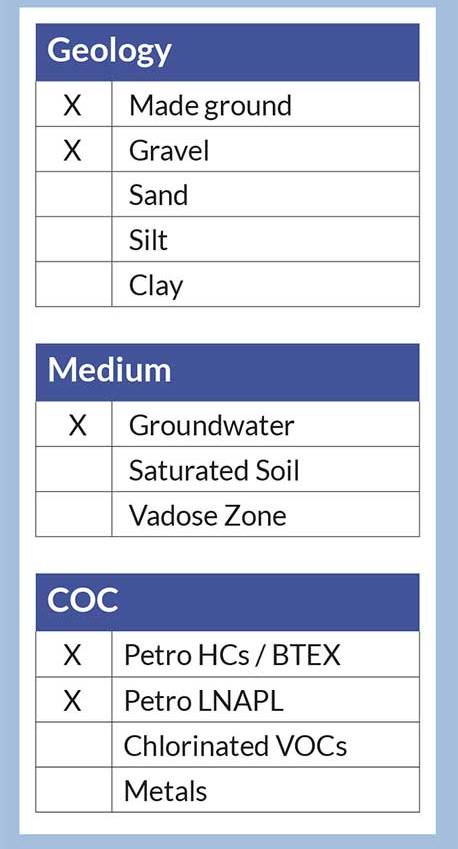

Shortlisted as one of the best Environmental & Sustainability projects in the UK Rail Awards 2018, this site is located in the south of England at a train care depot, where trains have been stored, repaired, cleaned and refuelled for over 20 years. A large number of fuel spill incidents (both historic and recent) have occurred over the years, centred on a fuel filling point.

Site investigations have revealed that these spillages have caused an area of the site to become highly contaminated. This includes the existence of a layer of fuel (Light Non-Aqueous Phase Liquid (LNAPL)), floating on top of the groundwater. This LNAPL was up to 2m thick in the source area, with an associated plume of dissolved petroleum hydrocarbon contamination migrating under the adjacent railway station towards residential properties offsite.

Further plume delineation and detailed quantitative risk assessment (DQRA), showed that the contamination presented a risk to offsite receptors and a potential liability to the site owner, making voluntary remediation advisable.

Remedial Design and Application

REGENESIS were asked by the Environmental Contractor already working on the site, to provide a suitable remediation strategy to address the LNAPL and provide treatment of the wider plume. The remediation had to be effective, whilst allowing for the considerable access constraints of the site, including active train tracks, continued operation of the fuelling point, limited work hours, subsurface services and the necessarily rigorous health and safety requirements of working on or near the line and adjacent to a conductor rail of this busy site (Personal Track Safety (PTS) scheme).

Our approach comprised an intensive 6-month treatment programme to remove LNAPL, reduce adsorbed contaminant mass in the smear zone and then apply a treatment to enhance the degradation of the residual dissolved phase contamination. As the site still actively fuels trains, the validation monitoring has been coupled with improved fuel handling, spill response and monitoring practices.

The first phase comprised the installation of a pump and treat (P&T) system enhanced with PetroCleanze in order to rapidly remove the LNAPL and adsorbed contamination in the smear zone. 18 treatment wells and 10 monitoring wells were installed across the target area: along the access road, the fuel point and within the four foot and six foot of the rail.

The P&T system was operated for a month in order to remove the easily-accessible LNAPL. Following this, the pumps were switched off, PetroCleanze was injected into the treatment wells and left in situ for one week. PetroCleanze creates a temporary and localised desorption-event in the subsurface, moving soil-bound Total Petroleum Hydrocarbons (TPH) from the smear zone into the groundwater, where it can then be removed by pumping. This has the effect of making the P&T system significantly more effective:

- Removing more contamination over time;

- Removing a much greater amount of contamination for the same time and cost of a typical P&T system;

- Reducing the active pumping period onsite; and

- Avoiding rebound following shut-down of the system.

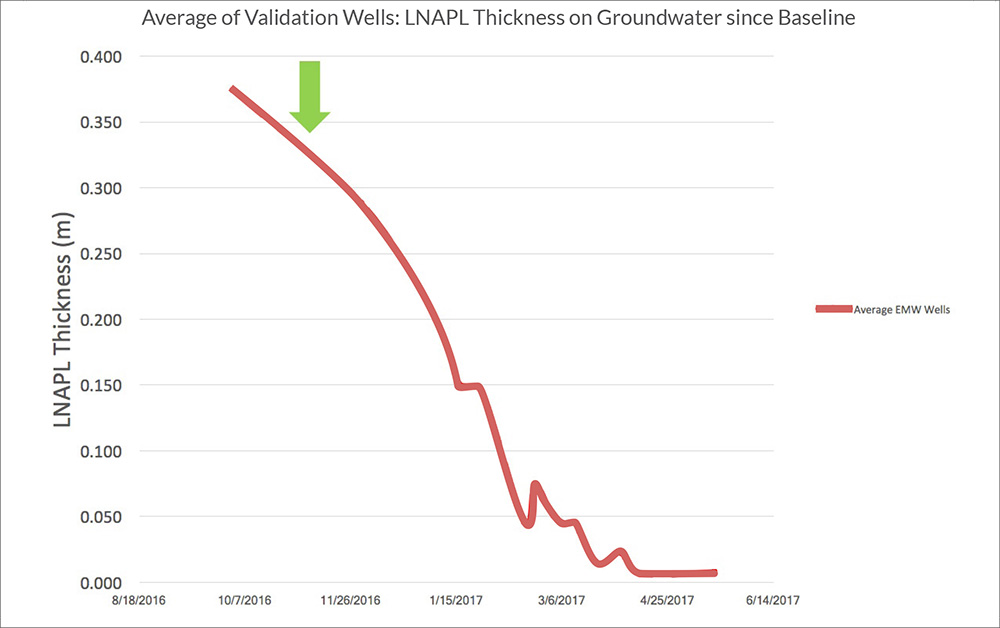

After one week, desorbed contaminant mass was observed in the monitoring wells and the P&T system was switched back on. After two weeks of pumping, the process was repeated. The graph below shows how the LNAPL thickness is reduced during pumping and increases due to enhanced desorption during PetroCleanze applications. It can be seen that the ‘rebound’ caused by each consecutive PetroCleanze injection is lower than the prior one, indicating a reduction in adsorbed contamination following each event.

Once four PetroCleanze applications had been completed and the rebound pumped out, the LNAPL and adsorbed contamination had been significantly reduced. This allowed the P&T system to be switched off and the residual contamination to be addressed using In Situ Chemical Oxidation (ISCO) and Enhanced aerobic Natural Attenuation (ENA).

RegenOx was applied to provide rapid degradation, by ISCO, of a portion of the residual sheen and dissolved phase contamination. RegenOx uses a controlled oxidant release and a built-in catalyst to provide prolonged (4-5 week) surface-mediated chemical oxidation of groundwater contamination. This allows for a powerful ISCO treatment while maintaining safe site/working conditions, i.e. without increased temperature or pressure in the subsurface. RegenOx also does not damage subsurface services and footings and so is ideal to use on an active facility such as this

ORC Advanced was also applied at the same time as the RegenOx, in order to accelerate the natural biological degradation of the residual dissolved phase contamination. ORC Advanced has a patented Controlled Release Technology that ensures the available oxygen in the product is released over a 9 to 12 month period without any loss to the atmosphere. This creates and maintains the ideal conditions for the growth of an aerobic biomass that will degrade the residual dissolved phase contamination at a rate of 10-100 times that of typical natural attenuation.

Conclusion

REGENESIS worked closely with the Site Owner, Regulator, Environmental Contractor, Waste Water Undertaker, Consultant and P&T specialist in order to provide a holistic approach to the site. The remediation strategy addressed the liability associated with historic and recent contamination, targeting LNAPL, adsorbed and dissolved phase contamination on the site.

The treatment comprised the integrated solution of an augmented system combined with in situ remediation, which provided:

- Rapid and effective removal of LNAPL;

- Temporary desorption and removal of secondary source area;

- Significant reduction in groundwater concentrations;

- A cost effective solution;

- No disruption to site operations.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español