Enhanced anaerobic bioremediation treats chlorinated solvents

Summary

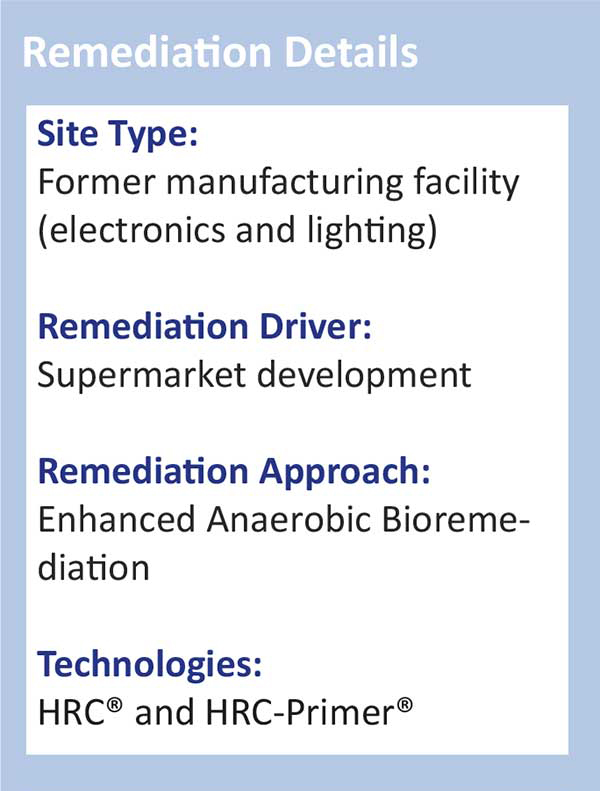

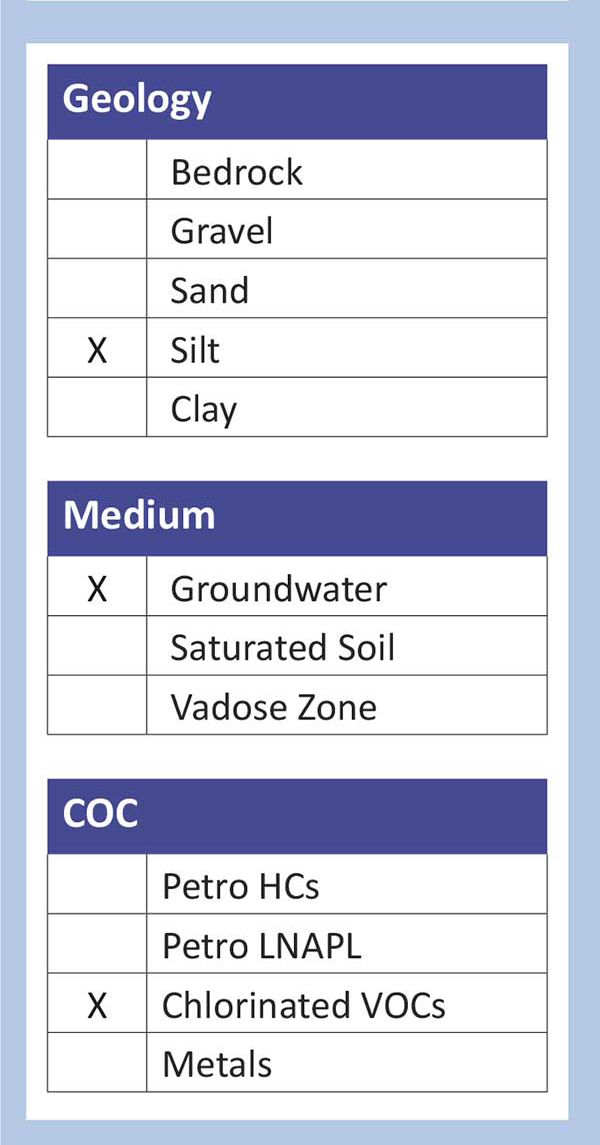

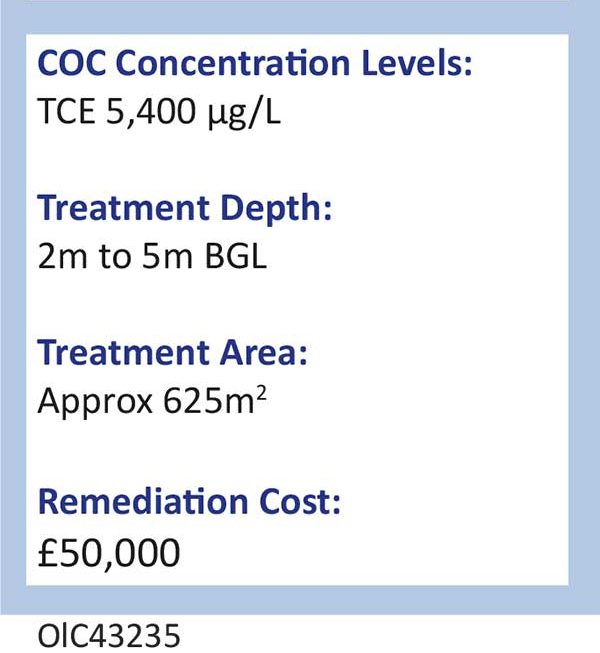

Significant chlorinated solvent contamination was discovered during the redevelopment of a former electronics manufacturing facility into a supermarket located in the Midlands. The majority of the contaminated soil had been excavated, however; high concentrations of TCE contamination was present beneath a number of trees on site which were protected by a Tree Preservation Order (TPO).

Initially a pump and treat (P&T) system was installed but was not able to meet remedial objectives and had become asymptotic.

Treatment

Hydrogen Release Compound® (HRC) was selected to enhance the natural process of anaerobic bioremediation, a proven remedial method that is effective at reaching low contaminant remedial targets whilst causing no adverse effects to the environment.

HRC was applied to the 615m2 source area via direct-push to 95 No. injection points in a 3m by 3m grid spacing. A line of injections formed a barrier at the site boundary preventing off-site contaminant migration.

What’s Special?

Whilst conventional remedial approaches – excavation and P&T – were not viable options or could not meet targets, enhanced anaerobic bioremediation was able to be applied even where access was difficult and meet remedial targets, with no adverse effect on the protected trees in the target area.

Remedial works satisfied regulatory objectives gaining site closure, allowing the land transaction to be completed and the construction programme to be met.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español