98-99% concentration reduction within 18 months using 3‐D Microemulsion® (3DMe) for in situ reductive dechlorination

Introduction

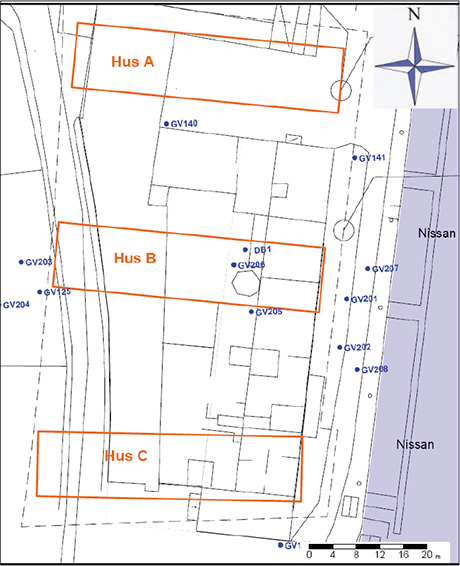

Remediation works were required at the Söderkaj site, in order to allow the completion of a large housing development project comprising the construction of 330 apartments in an attractive area along the shore of the river Nissan in Halmstad, Sweden. Historical activities at the site, including fisheries, metal plating, dry cleaning and maritime industries, have led to chlorinated solvent contamination in groundwater and PAH and metal contamination in the shallow soils. The hydrogeological conditions for the area are controlled by seasonal variations dependant on precipitation and sea levels.

Monitoring and infiltration tests have shown that the groundwater level in the area is approximately 1‐2m BGL and the soil profile is known to be highly variable to a depth of 7‐9m BGL. Shallow soils contaminated with PAH and metals were excavated and removed. Membrane interface probe (MIP) data was used to delineate both the vertical and lateral extent of the chlorinated solvent contamination at the site. Groundwater contamination was determined to exist between 3 to 6 m BGL.

4m 25s reading time

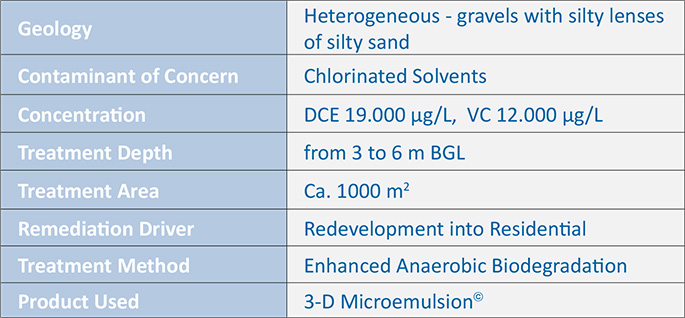

Fig. 1 Site Location along the Nissan River

Groundwater Remedial Strategy

3‐D Microemulsion (3DMe®) uses a 3‐stage donor release profile allowing for the immediate, mid-range and long-term release of hydrogen into the groundwater. The hydrogen is used to increase the mass and activity of the indigenous microorganisms performing reductive dechlorination. 3DMe is mixed with water to form a microemulsion for injection. Details of the injection are given in Table 1. The remedial objective was to reduce concentrations of chlorinated solvent contamination in the groundwater to below the site specific target level (SSTL) of 100μg/L in order to ensure the minimisation of the potential risk posed to human health.

- DCE Maximum Concentration – 19,000μg/L at MIP8 (before treatment)

- VC Maximum Concentration – 12,000μg/L at GV208 (before treatment)

3DMe application was undertaken in two stages to allow for demolition works onsite. Phase one, undertaken in June 2008, included the injection of 3DMe into the eastern and western portions of the plume. Phase two, undertaken in June 2009, included the injection of 3DMe in the previously inaccessible central plume area. The use of the high volume and self‐distributing properties of 3DMe allowed the number of injection points to be minimized, ensuring low application costs.

Figure 2: Site Layout with 3DMe treatment areas

Results

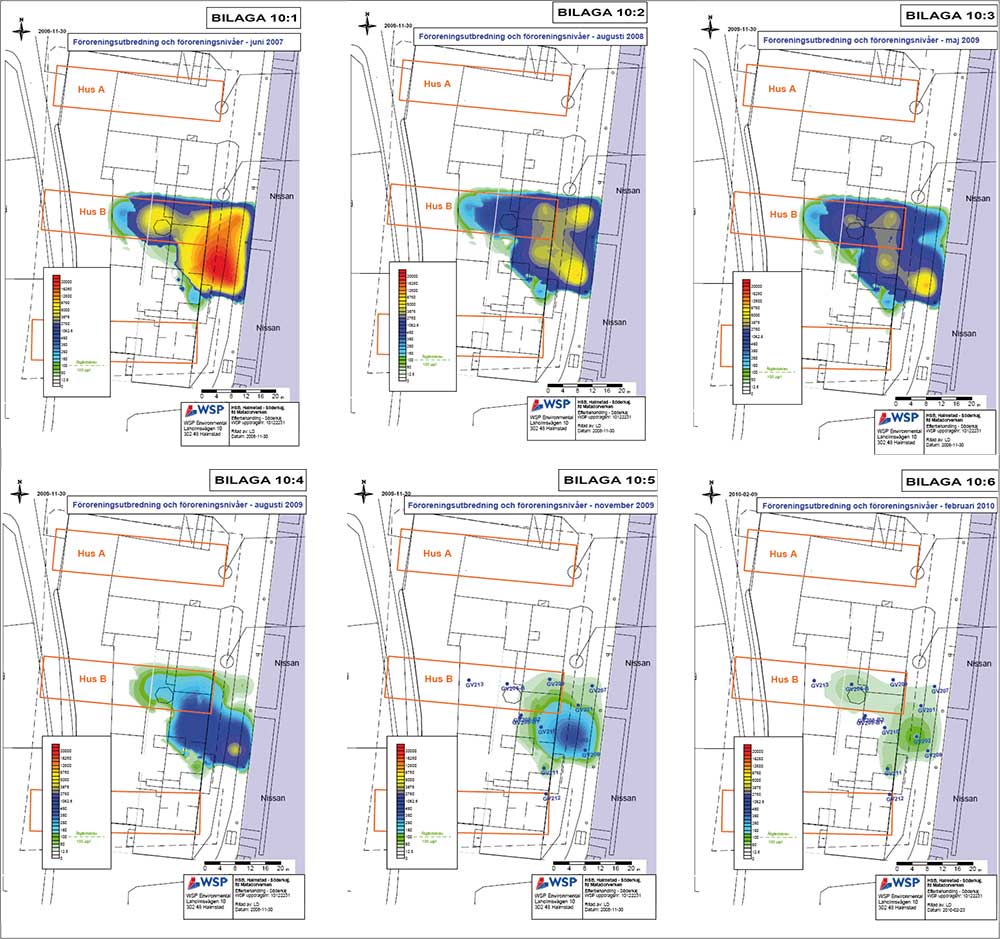

Chlorinated solvent treatment was very successful, achieving a 98 – 99% reduction in concentrations within 18 months across all treatment locations (Figure 4). The success of the project was both supported and validated by the use of MIP data to get vertical plume delineation.

The degree of dechlorination was calculated to determine the progress of the reductive dechlorination on site. During the course of the works, full reductive dechlorination was observed as concentrations of DCE and VC were broken down to ethene. Geochemical indicators suggested that conditions for reductive dechlorination were established soon after each of the application events. Competing electron acceptors (e.g. oxygen, nitrate, sulphate etc), present in the treatment area prior to the injection works, were rapidly reduced and total organic compounds (TOC) increased.

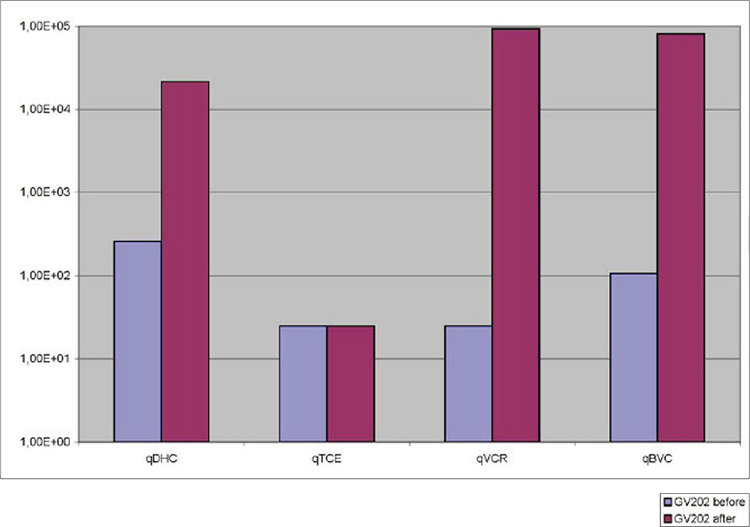

Quantification of microbial populations pre‐ and post‐phase one treatment works, clearly demonstrated that the microbial populations had increased (Figure 5) and were supported by the controlled supply of hydrogen from 3DMe to the treatment area. This was complimented by a corresponding increase in the degradation rate after the treatment was undertaken.

Fig.3 – 3DMe emulsion mixed with water prior to application

Fig 4 – Contaminant concentrations from pre‐ap- plication (Bilaga 10:1) through to final, post‐treatment (Bilaga10:6)

Compound Specific Isotope Analysis (CSIA) was undertaken as a final line of evidence. Transformation of organic compounds by biological processes can cause significant shifts in the ratios of 13C to 12C (δ13C) in both the reactants and products of the reaction. This occurs as a result of the stronger molecular bonds formed by the heavier isotope 13C in comparison to the 12C.

As a result, molecules with the lighter isotopes tend to be transformed more quickly, resulting in isotopic fractionation between the 13C in the residual reactant and of the 12C in the initial product. For example, isotopic fractionation was reported for both DCE (‐9.1 to +5.2‰) and VC (‐22.0 to +27‰ ) at location GV208 between May 2008 and February 2010. This is evidence that the reduction in chlorinated solvent concentrations was not the result of abiotic processes such as physical dilution and dispersion, as isotope fractionation typically only occurs due to biological degradation of the chlorinated solvents.

Conclusion

3DMe was applied to the groundwater in order to enhance the biodegradation of the chlorinated solvents onsite and allow redevelopment of the site.

- Within two months of the 3DMe application, enhanced reductive dechlorination was observed;

- This was evidenced by:

- Sequential production and degradation of daughter compounds

- The geochemistry of the aquifer showing conditions ideal for reductive dehalogenation

- An increase in biomass and activity of a reductive dechlorinator microbial consortia

- Isotopic fractionation between the parent and daughter compounds resulting from degradation

- An overall reduction in chlorinated compound concentrations in the groundwater

Contaminant levels throughout the plume were reduced to below the SSTLs within 18 months of the 3DMe application and regulatory acceptance for redevelopment of the site was secured.

Fig. 5 ‐ Bacterial Counts Pre‐ & Post‐Treatment

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español