ORC Advanced Socks

Replaceable, ORC Advanced® Socks for Localised Aerobic Biodegradation of Petroleum Hydrocarbons

Advanced Oxygen Release Compound Socks have been designed by REGENESIS to allow for a localised treatment approach of low-level, dissolved-phase petroleum hydrocarbons.

How it Works

Socks are permeable, fabric sleeves filled with pure ORC Advanced controlled-release oxygen material. Each Sock is inserted into a flexible plastic mesh for ease-of-application and maximum durability. The Socks are tied together and lowered into treatment wells onsite. When placed into groundwater or hydrated, the Socks provide a controlled-release of molecular oxygen for periods of up to 12 months from a single application. This dissolved oxygen is used by microorganisms to transform organic contaminants into carbon dioxide, water and microbial cell mass.

ORC Advanced Socks create and maintain ideal conditions for aerobic biodegradation, resulting in enhanced attenuation rates up to 100 times faster than under natural conditions. ORC Advanced Filter Socks provide remediation practitioners with a safe and highly effective means of treating petroleum contaminated sites.

Designed for Localised In-Well Treatment

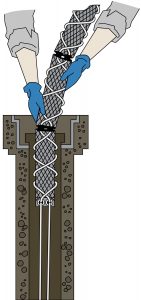

ORC Advanced Socks are designed to deliver controlled-release oxygen into a specific well or treatment area with the purpose of creating a very limited and localised aerobic zone where accelerated biodegradation can occur. Upon exhaustion of their oxygen supply (anywhere from 9-12 months) the socks can be removed, disposed of and replaced with a new one.

The Socks are 300 mm long and designed specifically to fit 50 mm diameters wells. They are easily laced together using the rope that is supplied with each Sock order. Regenesis ORC Advanced Socks include a factory installed, coloured, Naltex™ Flex-Guard to provide a durable finish and allow easy installation and extraction.

Target Contaminants:

- Benzene, Toluene, Ethylbenzene and Xylene (BTEX)

- Gasoline Range Organics (GRO) (C6-C10-12)

- Diesel Range Organics (DRO) (C8-12-C24-26)

- Oil Range Organics (ORO) (C22-32)

- Creosote (coal tar)

- Methyl-Tertiary Butyl Ether (MTBE)

- Tert-Butyl Alcohol (TBA)

- cis-1,2 Dichloroethene (DCE)

- Vinyl chloride (VC)

For a complete listing of treatable contaminants please visit our Range of Treatable Contaminants Page.

Benefits

- Available oxygen increases biodegradation up to 100 times faster than natural attenuation

- A single Sock application can support aerobic biodegradation for up to 12 months

- Replaceable delivery mechanism for controlled-release oxygen in existing wells

- Minimal site disturbance, no permanent or emplaced above ground equipment, piping, tanks or power sources

- Simple and easy application

- Low operation and maintenance cost– lower costs and greater efficiency/reliability than engineered mechanical systems, oxygen emitters or bubblers

- Wide local, national and international regulatory understanding and acceptance

Typical Groundwater Remediation Application Methods:

- Single or multiple well application into groundwater

Next Steps:

If you currently have a project and need a remediation solution now, visit our Request a design page.

Have questions or want to explore some ideas? Contact Us to get in touch with a local representative.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español