Former Service Station Treated on Native American Reservation Land

Combined Remedies Used to Remediate BTEX Contamination

Project Highlights

- Enhanced Aerobic Bioremediation and In Situ Chemical Oxidation used to treat high BTEX levels on-site

- Previous remediation activities included soil excavation but contamination persisted

- One application area located in lot used for beef cattle on reservation land and special approvals were required

- Project was state-funded by Pollution Liability Insurance Agency (PILA) of Washington but regulated by Region 10 EPA resulting in extensive coordination between both agencies

Project Summary

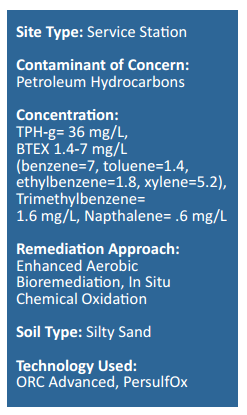

This Wapato, Washington site was a former gas station with historical releases dating back to at least 1995. It is located on a Native American Reservation so the site is regulated through Region 10 of the EPA.

The initial remedial activities consisted of excavation of source area soil but contamination remained. Considering the persistent contamination, the goal of the site was to reduce the remaining concentrations to meet regulatory goals.

Remediation Approach

A combied remedies strategy was devised for this site, including in situ treatment in three separate areas. Two areas were treated with both PersulfOx® and ORC® Advanced.

The third area was an empty lot that was used for ranging beef cattle. The client had concerns about how the treatment might affect the cattle, so only ORC Advanced was applied to this area because it is both insoluable and non-toxic. Because the entire site was located on reservation land it required special approvals by the tribal irrigation office before the injections could occur. A total area of 4,100-square-feet was treated for high levels of BTEX. Monitoring is ongoing.

Technology Description

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled-release of molecular oxygen for periods of up to 12 months upon hydration.

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español