Sustainability In Remediation

All across the globe, contaminated soil and groundwater creates a risk to the environment and human health. The challenge is how to remediate such widespread pollution problems without exacerbating another pressing global issue: climate change.

REGENESIS provides sustainable in situ remediation solutions. Our technologies enable contaminated land professionals to minimize the environmental impacts of their projects and reduce the carbon footprint of their clients’ supply chain.

How do we compare?

Explore the sustainability comparison studies below.

Sustainability Case Study

PFAS

We asked Ramboll’s Circular Solutions and Climate Specialist team to undertake a comprehensive sustainability study comparing our approach to pump and treat.

This focused on an international airport where a PlumeStop® barrier is being used to remediate PFAS contamination. The study includes crade-to-grave Life Cycle Analysis, Life Cycle Cost Analysis and a Tier 2 sustainability assessment.

Learn more about our sustainable approach in this explainer video:

1 Sustainability of in situ and ex situ remediation of PFAS contaminated groundwater (05.15.2023); Ramboll; using ‘cradle to grave’ carbon footprint analysis, full product-level Life Cycle Analysis, Life Cycle Cost Analysis and Sustainability assessment using Ramboll’s SURE model (Tier 2 assessment in line with ISO, ASTM standards and SuRF-UK guidance)

Sustainability Case Study

Chlorinated Solvents

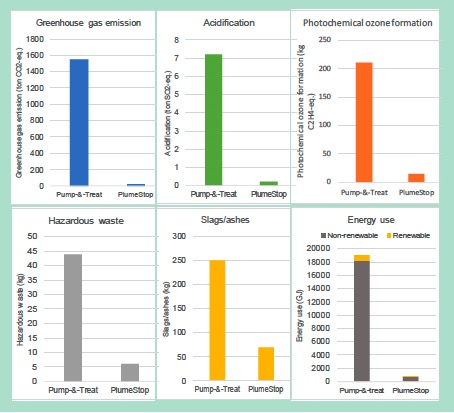

The Danish Environmental Protection Agency published a report analysing the sustainability of an in situ PlumeStop treatment of a chlorinated solvent plume using Life Cycle Analysis and a Tier 2 sustainability assessment. The approach was then compared to a potential pump-and-treat system and shown to be much more sustainable across all parameters.

Read the report to learn why PlumeStop came out as the most favourable remediation option.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español