If you currently have a project and need a remediation solution now, visit our Request a Design page.

Have questions or want to explore some ideas? Contact Us to get in touch with a local representative.

3-D Microemulsion® is an injectable liquid material specifically designed for in situ remediation projects where the anaerobic biodegradation of chlorinated compounds through the enhanced reductive dechlorination (ERD) process is possible. ERD is the primary anaerobic biological process by which problematic chlorinated solvents such as tetrachloroethylene (PCE) and trichloroethene (TCE), dichloroethene (DCE) and vinyl chloride (VC) in groundwater are biologically transformed into less harmful end products such as ethene.

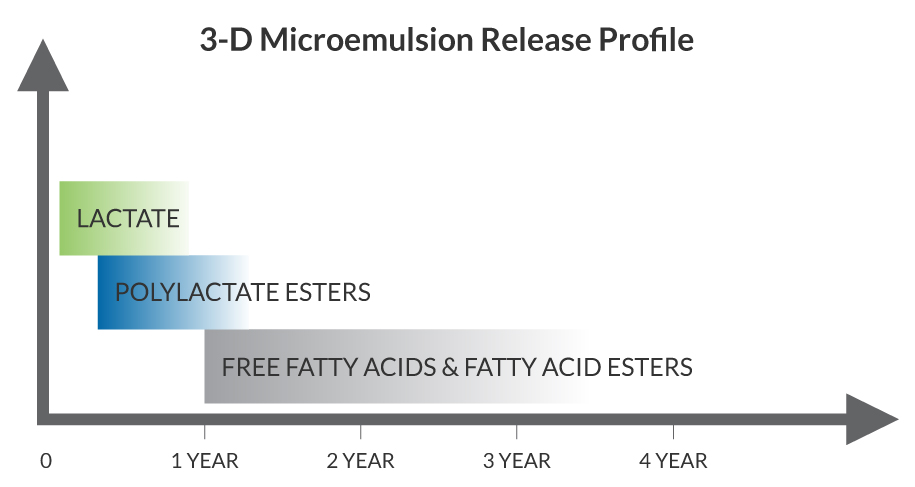

Due to its purposefully engineered structure, 3-D Microemulsion exhibits unique subsurface distribution characteristics which allow it to propagate widely within the subsurface. As a result, 3-D Microemulsion can treat a wide-areas around an individual injection point saving both time and money as it relates to the number of application points required. Building on the 3-D Microemulsion engineered molecular structure, this product is designed to provide three unique electron donor materials in a single product. This design produces a beneficial and sequential, staged-release of its three individual electron donor components (Figure 2). This results in an immediate, mid-range and long-term, controlled-release supply of organic acids to fuel the ERD process. Staged-release offers the ERD optimizing benefit of supplying just the right amount of electron donor needed for periods of up to 2-4 years on a single application. Without staged-release technology the ERD process is forced to sub-optimally speed up, then slow down or even stop in some cases. This negatively affects contaminant degradation efficiency and rates leading to longer project timelines and potentially higher volumes of commodity electron donor usage.

The 3-D Microemulsion Sequential, Electron Donor Staged-Release Profile:

The immediately available free lactic acid (lactate) is fermented rapidly

The controlled-release lactic acid (polylactate ester based portion) is metabolized at a more controlled rate

The free fatty acids and fatty acid esters are converted to hydrogen over a mid to long-range timeline giving 3-D Microemulsion an exceptionally long electron donor release profile

For a complete listing of treatable contaminants please visit our Range of Treatable Contaminants Page.

The objective of this study is to asses the effects of adding soluble divalent iron (DVI) to emulsified electron donor mixtures to promote the biogeochemical destruction of TCE, PCE, cis-1,2 DCE, and VC in groundwater. 24 projects sites were studied, comprising 100 performance monitoring wells across the US. Wells that received the DVI showed increased dechlorination rates, improved contaminant reduction, and limited daughter product formation relative to the wells that did not receive the DVI.

The objective of this study is to asses the effects of adding soluble divalent iron (DVI) to emulsified electron donor mixtures to promote the biogeochemical destruction of TCE, PCE, cis-1,2 DCE, and VC in groundwater. 24 projects sites were studied, comprising 100 performance monitoring wells across the US. Wells that received the DVI showed increased dechlorination rates, improved contaminant reduction, and limited daughter product formation relative to the wells that did not receive the DVI.

If you currently have a project and need a remediation solution now, visit our Request a Design page.

Have questions or want to explore some ideas? Contact Us to get in touch with a local representative.

3-D Microemulsion® (3DME) is an injectable liquid material specifically designed for in situ remediation projects where the anaerobic biodegradation of chlorinated compounds through the enhanced reductive dechlorination (ERD) process is possible.

3-D Microemulsion (3DME) is an injectable liquid material which aids in the anaerobic biodegradation of chlorinated compounds. This product provides three unique electron donor materials which produce a beneficial and sequential, staged-release of each individual electron donor component. 3DME exhibits unique subsurface distribution characteristics which allow it to propagate widely within the subsurface. As a result, 3DME can treat wide-areas around an individual injection point saving both time and money.

3-D Microemulsion is right for your project if you are looking for a long-term source of staged-release hydrogen to aid in the anaerobic biodegradation of chlorinated compounds.