In Situ Chemical Oxidation with Minimal Exothermic Reactivity and Compatibility with Underground Infrastructure

- Promotes rapid and sustained in situ oxidation of a wide-range of organic contaminants

- Provides a unique catalytic surface on which oxidants and contaminants react in a process known as “surface mediated oxidation”

- Non-corrosive, with minimal heat and pressure – compatible with underground infrastructure, tanks, piping, etc.

- Creates a significant, short-term oxygen footprint to quickly establish follow-on aerobic biodegradation conditions

- Readily desorbs contaminants from soil surfaces allowing for more effective ISCO and/or mechanical removal/extraction

- Longer-term ISCO reactivity on the order of 30 days post-injection

- Easily applied with readily available equipment

RESOURCES

A Two-Part System Producing Powerful Chemical Oxidation Reactions

RegenOx® in situ chemical oxidation (ISCO) directly oxidizes contaminants while its unique catalytic component generates a range of highly oxidizing free radicals that rapidly and effectively destroy a range of target contaminants including both petroleum hydrocarbons and chlorinated compounds. RegenOx is an injectable, two-part ISCO reagent that combines a solid sodium percarbonate based alkaline oxidant (Part A), with a liquid mixture of sodium silicates, silica gel and ferrous sulfate (Part B), resulting in a powerful contaminant destroying technology.

Once emplaced in the subsurface, RegenOx produces a cascade of highly-efficient chemical oxidation reactions via a number of mechanisms including:

- Surface mediated oxidation

- Direct oxidation

- Free radical oxidation

These reactions destroy a range of contaminants and can be propagated in the presence of RegenOx for periods of up to 30 days on a single injection.

RegenOx produces minimal heat and pressure and is non-corrosive making it a relatively safe chemical oxidant that is compatible for use in direct contact with underground infrastructure such as utilities, tanks, piping communication lines, etc. As a result the material can be applied using a wide-range of standard field equipment (e.g. direct push injection rigs) or applied directly into excavations.

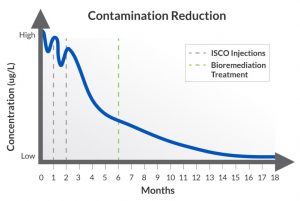

In addition to chemical destruction, RegenOx ISCO produces a significant, short-term oxygen footprint that is optimal for establishing aerobic conditions capable of supporting follow-on, aerobic biodegradation of petroleum hydrocarbons. Once aerobic conditions are in place, many remediation practitioners apply Oxygen Release Compound Advanced (ORC Advanced) with or after RegenOx to support long-term aerobic biodegradation. This “ISCO to bio” combined remedies approach can be highly effective at reducing a range of contaminant concentrations and associated costs.

Finally, RegenOx based-reactions produce mild, detergent-like effects that desorb or remove contaminants off of soil surfaces and transfer contaminants more readily into the dissolved-phase. This process of removing material from soil surfaces has also been proven to be highly effective at increasing the efficiency of established, groundwater pump and treat (P&T) systems that have gone asymptotic. This desorption effect has been optimized in a specialized version of RegenOx called PetroCleanze which is designed for use in enhancing and optimizing multi-phase extraction (MPE) activities and P&T systems during site remediation.

Finally, RegenOx based-reactions produce mild, detergent-like effects that desorb or remove contaminants off of soil surfaces and transfer contaminants more readily into the dissolved-phase. This process of removing material from soil surfaces has also been proven to be highly effective at increasing the efficiency of established, groundwater pump and treat (P&T) systems that have gone asymptotic. This desorption effect has been optimized in a specialized version of RegenOx called PetroCleanze which is designed for use in enhancing and optimizing multi-phase extraction (MPE) activities and P&T systems during site remediation.

TARGET CONTAMINANTS:

For a complete listing of treatable contaminants please visit our Range of Treatable Contaminants Page.

Petroleum Hydrocarbons

- Benzene, Toluene, Ethylbenzene and Xylenes (BTEX)

- Gasoline Range Organics (GRO) (C6-C10-12)

- Diesel Range Organics (DRO) (C8-12-C24-26)

- Oil Range Organics (ORO) (C22-32)

- Creosote (coal tar)

- Methyl-Tertiary Butyl Ether (MTBE)

- Tert-Butyl Alcohol (TBA)

Chlorinated Compounds

- Chlorinated Solvents

- Tetrachloroethylene (PCE)

- Trichloroethene (TCE)

- cis-1,2 Dichloroethene (DCE)

- Vinyl chloride (VC)

- Tetrachloroethane

- Trichloroethane (TCA)

- Dichloroethane (DCA)

- Carbon tetrachloride

- Chloroethane

For a complete listing of treatable contaminants please visit our Range of Treatable Contaminants Page.

Soil Oxidant Demand (SOD) testing can be used to assess the suitability of an in situ chemical oxidation approach at your site and further estimate the amount of oxidant consumed by the soil matrix during ISCO applications. For more information download the Soil Oxidant Demand document.

Typical Applications

– Direct-push injection (barriers and grids)

– Specially designed injection wells

– Soil borings

– Excavation applications into soil or on top of bedrock

– Soil mixing, handling and milling approaches

Next Steps:

If you currently have a project and need a remediation solution now, visit our Request a Design page.

Have questions or want to explore some ideas? Contact Us to get in touch with a local representative.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español