Safe and Effective In Situ Chemical Oxidation (ISCO)

At a glance

-

Provides rapid contaminant destruction

-

Targets source areas of highly impacted groundwater

-

Surface mediated chemical oxidation avoids temperature and pressure build-up

-

Compatible with most construction materials allowing application near to infrastructure

Benefits

-

Highly effective at rapidly destroying large amounts of contaminant mass

-

Safe to use

-

Easy to mix and apply

-

Compatible with infrastructure

-

Treatment sustained for 4-5 weeks from a single injection

-

Combines well with aerobic biological degradation

-

Minimised loss to natural FOC on soils, through desorption and destruction of contamination in groundwater

-

Effective desorption reagent to enhance physical recovery techniques

TARGET CONTAMINANTS

Petroleum Hydrocarbons

-

Benzene, Toluene, Ethylbenzene and Xylenes (BTEX)

-

Gasoline Range Organics (GRO) (C6-C10-12)

-

Diesel Range Organics (DRO) (C8-12-C24-26)

-

Oil Range Organics (ORO) (C22-32)

-

Creosote (coal tar)

-

Methyl-Tertiary Butyl Ether (MTBE)

-

Tert-Butyl Alcohol (TBA)

For a complete listing of treatable contaminants please visit our Range of Treatable Contaminants Page.

Chlorinated Compounds

-

Chlorinated Solvents

-

Tetrachloroethylene (PCE)

-

Trichloroethene (TCE)

-

cis-1,2 Dichloroethene (DCE)

-

Vinyl chloride (VC)

-

Tetrachloroethane

-

Trichloroethane (TCA)

-

Dichloroethane (DCA)

-

Carbon tetrachloride

-

Chloroethane

APPLICATION METHODS

Typical applications include:

-

Direct-push injection

-

Injection into wells

-

Sprayed into excavation

Enhancing recovery techniques:

-

Multi-phase extraction

-

Vacuum tanker extraction

-

Pump and treat systems

For more information, please read the Application Instructions

ENGINEERED ISCO REAGENT

A two-part system that produces powerful chemical oxidation reactions

RegenOx® in situ chemical oxidation (ISCO) directly oxidizes contaminants while its unique catalytic component generates a range of highly oxidizing free radicals that rapidly and effectively destroy a range of target contaminants including both petroleum hydrocarbons and chlorinated compounds.

RegenOx is an injectable, two-part ISCO reagent that combines a solid sodium percarbonate based alkaline oxidant (Part A), with a liquid mixture of sodium silicates, silica gel and ferrous sulfate (Part B), resulting in a powerful contaminant destroying technology.

Once emplaced in the subsurface, RegenOx produces a cascade of highly-efficient chemical oxidation reactions via a number of mechanisms including:

- Surface mediated oxidation

- Direct oxidation

- Free radical oxidation

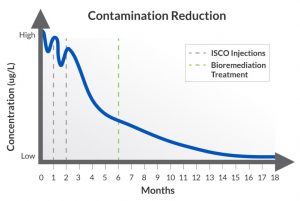

These reactions destroy a range of contaminants and can be propagated in the presence of RegenOx for periods of up to 30 days on a single injection.

RegenOx produces minimal heat and pressure and is non-corrosive making it a relatively safe chemical oxidant that is compatible for use in direct contact with underground infrastructure such as utilities, tanks, piping communication lines, etc. As a result the material can be applied using a wide-range of standard field equipment (e.g. direct push injection rigs) or applied directly into excavations.

In addition to chemical destruction, RegenOx ISCO produces a significant, short-term oxygen footprint that is optimal for establishing aerobic conditions capable of supporting follow-on, aerobic biodegradation of petroleum hydrocarbons. Once aerobic conditions are in place, many remediation practitioners apply Oxygen Release Compound Advanced (ORC Advanced) with or after RegenOx to support long-term aerobic biodegradation. This “ISCO to bio” combined remedies approach can be highly effective at reducing a range of contaminant concentrations and associated costs.

Finally, RegenOx based-reactions produce mild, detergent-like effects that desorb or remove contaminants off of soil surfaces and transfer contaminants more readily into the dissolved-phase. This process of removing material from soil surfaces has also been proven to be highly effective at increasing the efficiency of established, groundwater pump and treat (P&T) systems that have gone asymptotic. This desorption effect has been optimized in a specialized version of RegenOx called PetroCleanze which is designed for use in enhancing and optimizing multi-phase extraction (MPE) activities and P&T systems during site remediation.

Finally, RegenOx based-reactions produce mild, detergent-like effects that desorb or remove contaminants off of soil surfaces and transfer contaminants more readily into the dissolved-phase. This process of removing material from soil surfaces has also been proven to be highly effective at increasing the efficiency of established, groundwater pump and treat (P&T) systems that have gone asymptotic. This desorption effect has been optimized in a specialized version of RegenOx called PetroCleanze which is designed for use in enhancing and optimizing multi-phase extraction (MPE) activities and P&T systems during site remediation.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español