High Concentrations of Chlorinated Solvents Reduced to Non-Detect Allowing for Site Closure

The subject site has been used for the manufacture of industrial switchgear assemblies and warehousing since the 1970s. A subsurface investigation revealed a highly localized plume near WS10 with significant groundwater concentrations of trichloroethene (TCE) at 260 parts per million (ppm) along with its breakdown product cis-1,2- dichloroethene (cDCE). A site specific target level (SSTL) was established for TCE (1.0 ppm) and remedial action began with an in situ injection of Hydrogen Release Compound (HRC®). The product was chosen over other remedial strategies since the application would not disrupt on-site operations and did not require long-term maintenance.

Remediation Approach

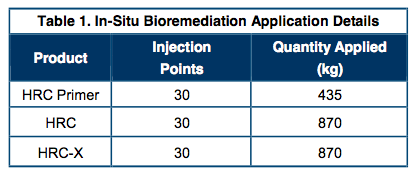

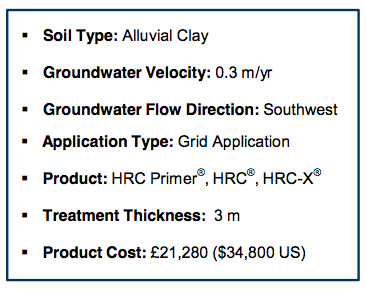

The remediation objective was to reduce concentrations of TCE to below the SSTL of 1.0 ppm. A combined approach using HRC Primer®, HRC and extended release, HRC-X®, was applied using a grid injection layout (Figure 1). HRC Primer was initially injected to quickly establish reducing conditions within the aquifer. The injection of HRC would sustain anaerobic conditions over the next 18 months while the addition of HRC-X would continue releasing hydrogen for approximately 5 years. Two new wells were installed to monitor the progress of remediation – BH1 and BH2. Well BH1 replaced future monitoring in WS10 while BH2 was installed downgradient. Sampling of both wells indicated a hot spot at BH1 and no elevated level of contamination in BH2.

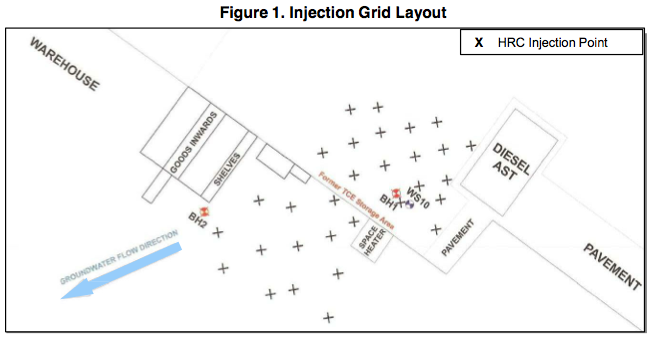

Monitoring results immediately following the HRC injection (November 2005) revealed TCE was present at BH1 but not at BH2 indicating no migration off-site was likely to occur. Breakdown products 1,1-dichloroethene (1,1-DCE), trans-1,2- dichloroethene (tDCE), and cDCE were present for the first time demonstrating a reductive dechlorination process had been established as a result of the HRC application. By January 2006, trace concentrations of vinyl chloride (VC) were detected for the first time indicating that complete dechlorination was occurring in the subsurface.

In September 2006, sampling results indicated TCE levels were below the SSTL of 1.0 ppm (Graph 1). Breakdown products continued to be detected however all were on a reducing trend.

CONCLUSION

Within 10 months, total chlorinated compounds in Well WS10/BH1 were reduced from 198 to 4.3 ppm, a 98% reduction. The TCE remedial goal was reached using one combined application of HRC Primer, HRC and HRC-X. The consultant and environmental agency agreed that the remaining chlorinated solvents would continue to reduce and no further action was needed. A request for site closure was granted in November 2006.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español