Powerful & proven remediation solutions

Extensive experience treating PFAS, chlorinated solvents and petroleum sites

Performance backed by data

Gallons of PFAS-contaminated groundwater treated in situ*

Zero waste. Zero liability. <1/3 the cost.

{counter}

*Gallons calculated based on cumulative groundwater flow through PlumeStop barriers completed to date. Number of barriers updated annually.

We tailor our solutions to your specific needs

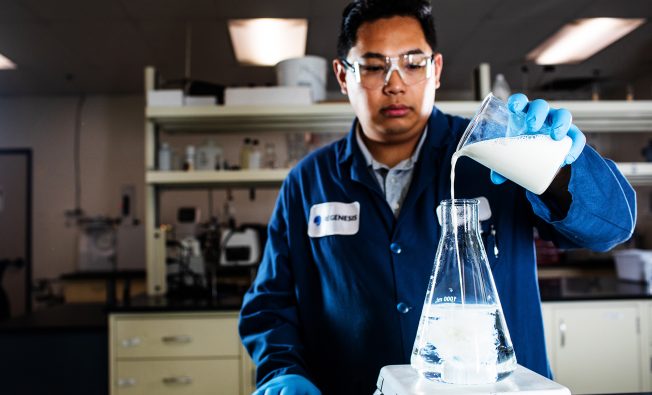

We offer advanced in situ remediation technologies, expert field services, and tailored design support — all delivered with one goal in mind: performance that lasts.

Glossary of contaminants treated

Environmental professionals trust us

We don’t just sell products. We help solve environmental challenges through proven remediation technologies and we back every solution with over 30 years of experience, validated data, and real-world results.

Third-party validated results ensure reliable remediation.

Proven efficiency

Fast turnaround times

Cost-effective solutions

Regulatory compliance

Over 40,000 successful projects worldwide

Saudi Arabia

Featured Case Study

PFAS Contaminants Reduced to Non-Detect

This case study reviews a bulk storage facility located in the Middle East region that had released a mixed plume of petroleum hydrocarbons and Per and Polyfluoroalkyl substances (PFAS). PFAS constituents were effectively reduced to non-detect following the application of PlumeStop and have remained at these levels for twelve months post-application.

Other case studies from Saudi Arabia

Canada

Featured Case Study

PlumeStop Cost-Efficiently Eliminates PFAS Long-Term

This case study reviews the first known full-scale in situ PFAS treatment worldwide completed in 2016 at a manufacturing and former firefighting training site in Ontario, Canada, where aqueous film-forming foams (AFFF) were used.

Other case studies from Canada

United States

Featured Case Study

PFAS Effectively Remediated at Former Naval Air Station Alameda

Historical firefighting activities at the former Naval Air Station (NAS) Alameda resulted in high PFAS (per- and polyfluoroalkyl substances) concentrations in the groundwater, threatening the Oakland Inner Harbor.

Sweden

Featured Case Study

Implementing a PlumeStop Barrier for PFAS Plume Control at Airport in Sweden

At Örnsköldsvik Airport in northeastern Sweden, significant groundwater PFAS contamination had been observed, primarily originating from a fire training ground where PFAS containing Aqueous Film-Forming Foam (AFFF) was discharged during firefighting exercises.

Other case studies from Sweden

Norway

Featured Case Study

In Situ PFAS Remediation Protects Offsite Environment at Airport in Norway

At Haugesund Airport in Norway, Avinor and their environmental consultant COWI implemented a remediation plan to reduce the migration of PFAS (per- and polyfluoroalkyl substances) in groundwater from a fire training ground

Other case studies from Sweden

Finland

Featured Case Study

Effective In-Situ Treatment of a 3,280 Ft. PCE Plume in Finland

In Eastern Finland, a fast-moving PCE (perchloroethene) plume beneath a metal-processing facility was remediated to reduce impacts on a municipal drinking water source. The demonstration project achieved PCE concentration reductions of approximately 80% in the plume within months and 90 to 95% by 18 months, ultimately reducing PCE to below the drinking water limit at the municipal water supply well.

Other case studies from Sweden

United Kingdom

Featured Case Study

High Levels of TCE Remediated at Former Chemical Manufacturing Facility, UK

With many site investigations and remediation attempts made over >30 years by other consultants and contractors, Vertase FLI was appointed to undertake the design, management and ultimate sign off of the remediation, which included ex situ bioremediation, asbestros management and a complex upfront site investigation and verification exercise.

Belgium

Featured Case Study

SourceStop Reduces PFAS by >99% at Belgian Factory Site

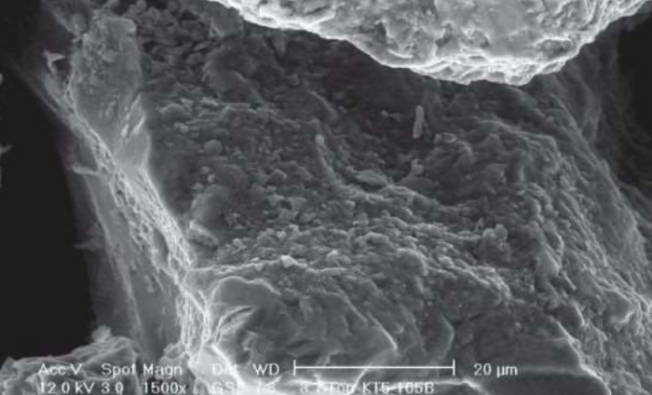

A textile manufacturing facility in Belgium used per- and polyfluoroalkyl substances (PFAS) in its manufacturing process. Over time, spills and leaks led to the accumulation of PFAS in the shallow soil, which eventually leached into the groundwater, forming a diffuse PFAS plume. SourceStop® – Liquid, a colloidal activated carbon (CAC) technology, was applied to reduce PFAS migration beneath the source area.

Other case studies from Belgium

Italy

Featured Case Study

DNAPL to Non-Detect: 6 Orders of Magnitude Reduction of Chlorinated Solvents

Combined in situ sorption and biological degradation leads to site closure of large manufacturing site in Northern Italy. Chlorinated solvents were used for many years at a former manufacturing facility in Northern Italy. This resulted in contamination of the groundwater underlying a large proportion of this 60,000 m2 site.

Other case studies from Italy

Netherlands

Featured Case Study

Double pilot study treats TPH at redevelopment site in the Netherlands

An area in the south west of the Netherlands is to be redeveloped into residential properties. High levels of petroleum hydrocarbons (kerosene, lamp oil and fuel) up to NAPL, had been found at the site. Remedial action was required to reduce the risk to potential new residents. The environmental company ATKB decided to complete a double pilot trial with PetroFix®. Full-scale treatment has been planned to commence within 12 months of the pilot application. Read the profile to learn what the pilot trial entailed.

Other case studies from Sweden

Spain

Featured Case Study

Effective 3-D Microemulsion Treatment of a CrVI Plume, Enables Site Redevelopment in Spain

In a town in Spain’s Basque Country, a former cutlery manufacturing site contaminated with hexavalent chromium (CrVI, Cr6) was slated for redevelopment into retail use. High CrVI concentrations in the groundwater—originating from historic plating operations—posed a significant risk to a nearby river.

France

Featured Case Study

Successful standalone treatment of a large plume with difficult site conditions

The process of Enhanced Reductive Dechlorination (ERD) for the biological degradation of chlorinated compounds, is now a widely used and proven in situ remediation approach. Nevertheless, ERD is often used only as a ‘polishing step’ of the plume, rather than a stand-alone primary remediation technology.

Germany

Featured Case Study

Preventative treatment at a chemical plant

A new underground pipeline was required to be installed across a complex chemical plant in southwestern Germany. It was found that part of the pipeline would intersect an area of soil and groundwater impacted with petroleum hydrocarbons and BTEX compounds.

Other case studies from Germany

Switzerland

Featured Case Study

In Situ Reduction of Hexavalent Chromium

At a former precision component manufacturing facility in Northern Switzerland, hexavalent chromium contamination was found in the underlying soil and groundwater. The challenge for Environmental Consultant CSD Ingénieurs was to find an effective remediation solution that allows business activities to continue, keeps costs low and avoids the demolition of historic buildings. Read the case study to learn how this puzzle was solved with the help of our products and services.

Other case studies from Belgium

Poland

Featured Case Study

Combined ISCR and ERD Remedial Approach Knocks Down PCE Concentrations in Poland

Rapid groundwater treatment achieved at manufacturing plant, without daughter product build-up. At an active manufacturing plant in the region of Greater Poland, in the West of the country, historical perchloroethylene (PCE) contamination was found to be impacting both soil and groundwater. Environmental company PROTE determined that contamination originated from a number of spills and leakages that occurred over the >20 years of manufacturing on the site.

Other case studies from Belgium

Performance-driven technologies, designed to deliver

Innovative, patented colloidal technologies

Have a challenge?

Let’s solve it together.

Contact us today to discuss your specific needs.