Inline Blending and

Injection System (IBIS)

IBIS - Inline Blending and Injection System elevates your remediation project

to new levels of efficiency, accuracy, and safety. Groundbreaking in its design

and capabilities, IBIS represents the peak of technological advancement for

in situ remediation.

Welcome to the Future of In Situ Remediation

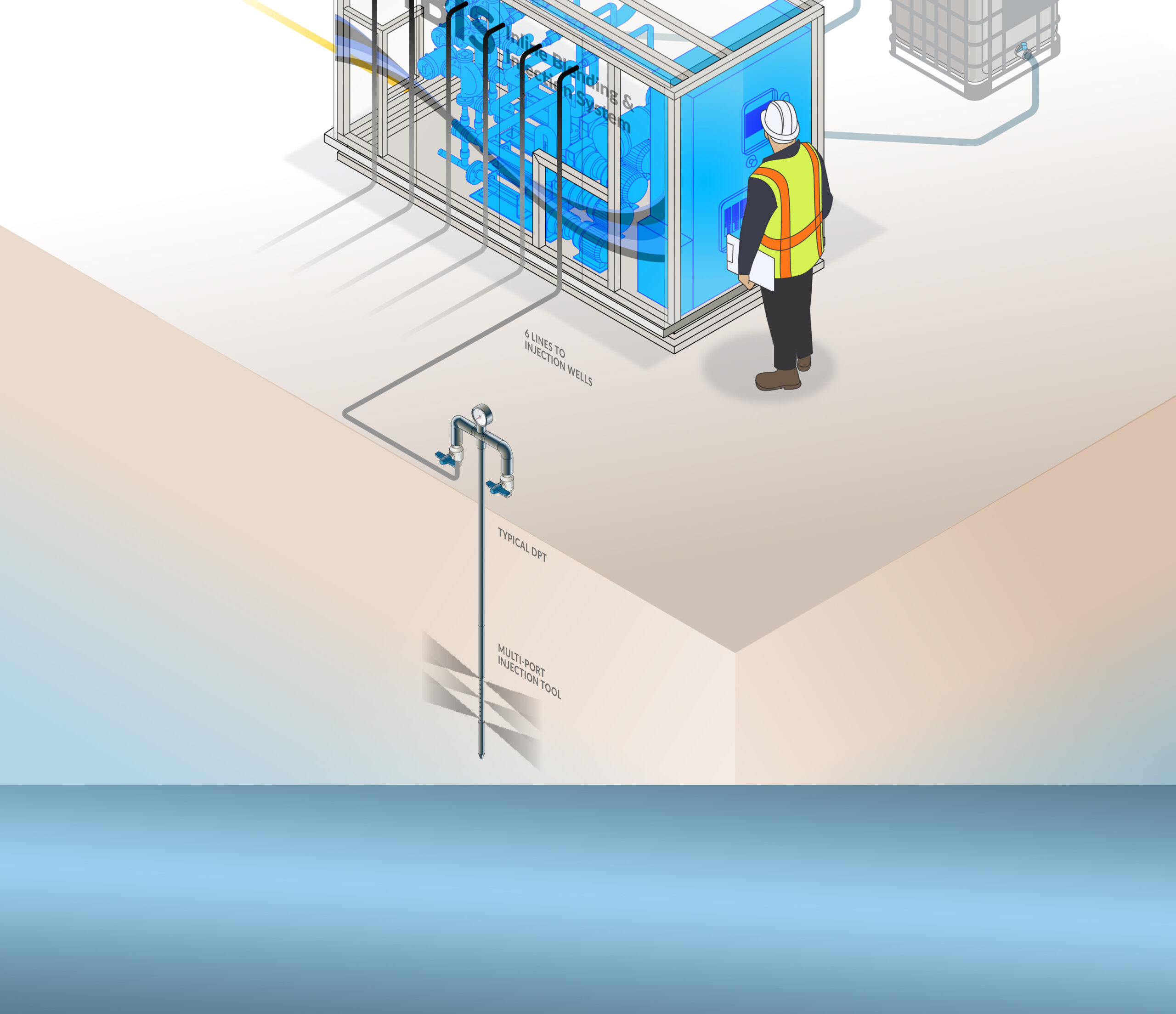

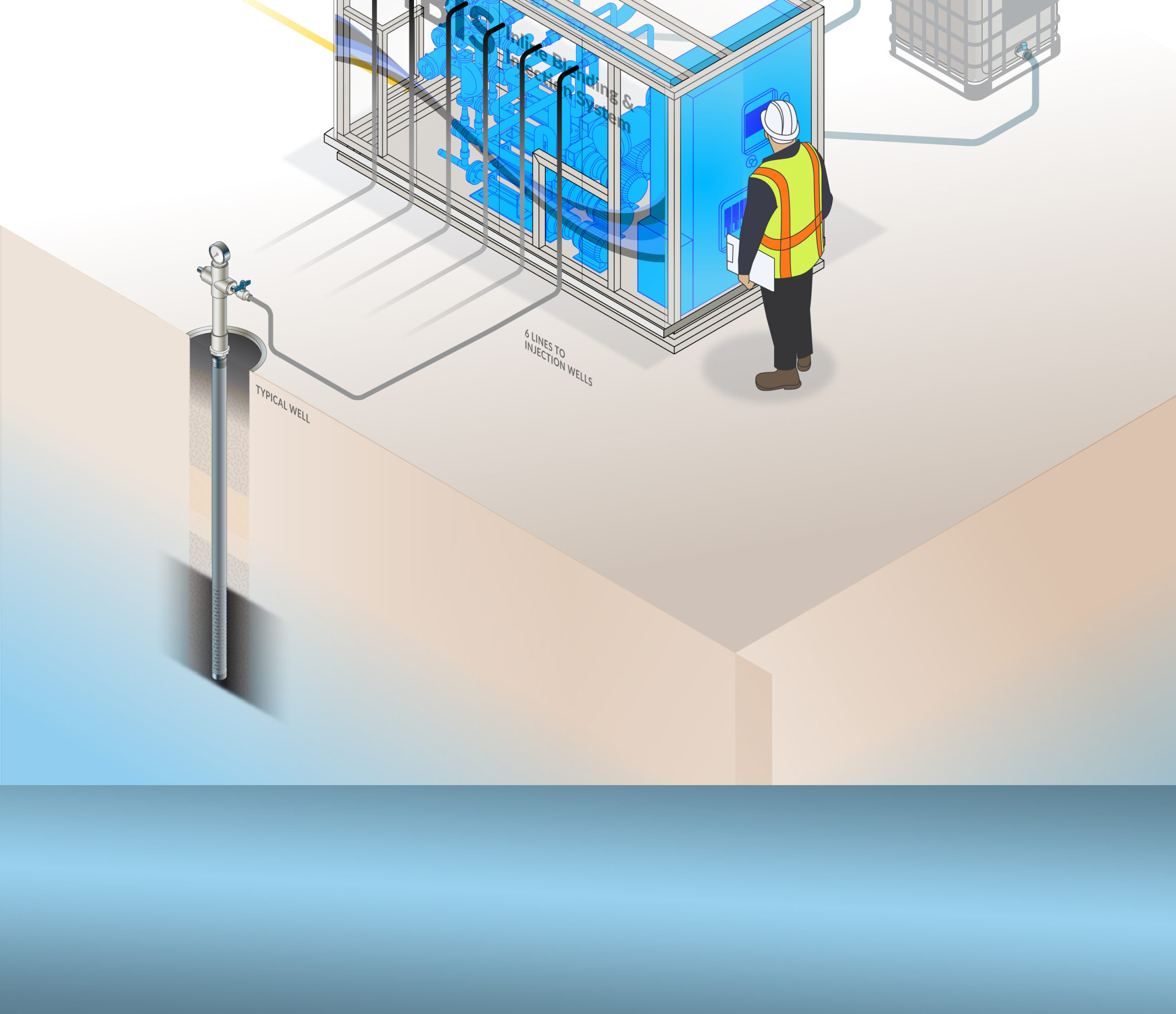

IBIS is a self-contained, compact remediation amendment delivery system that enhances the efficiency, accuracy and safety of in situ remediation applications.

How Does IBIS Work?

IBIS mixes water with liquid remediation amendments and mechanically blends them through an inline static mixer to produce a final amendment blend for direct application into a treatment zone.

IBIS contains several positive displacement pumps that connect directly to bulk reagent storage containers and a water supply. Onboard electronic automation controls align the operation of these pumps and provide an accurate ratio control for each based on a user-defined flow rate. Using mass flow measurements in formulated ratios, IBIS ensures accurate amendment dosing and blending while eliminating the need for batch tank mixing.

What Are Its Capabilities?

IBIS can process up to four remediation amendments to deliver a final blended solution for injection at up to six separate delivery discharge lines simultaneously. IBIS’s electronic control features auto-adjust to regulate and maintain safe operating injection flow rates and pressures throughout the delivery system.

Injection flow rates, pressures and volume totals at each line are logged by IBIS continuously during operation. These and other pertinent injection data can be accessed in real-time to keep project stakeholders informed and guide remedial decision-making in the field without communication delays.

Key Benefits

Speed

- Inline mixer eliminates one-at-a-time ingredient mixing and batch tank agitation

- Faster amendment changeover

- Quicker setup and teardown

Accuracy

- Automated amendment dosing, mixing, and volume controls reduce variability

- User interface provides real-time data for cross-checking

- Programmable for depth-discrete dosing based on mass-flux

Safety

- Reduced material handling

- Elimination of large-volume batching reduces spill risks

- Automated safety controls maintains safe operating pressures

Real-Time Data

- Automated data collection

- Instantly downloadable and reviewable automated data

- Elimination of human error due to manual entry

What are the Benefits

of Using IBIS?

Accelerating Efficiency

By streamlining processes, IBIS picks up the tempo of remediation applications and reduces time in the field. With an inline blending technology capable of mixing up to four products simultaneously, IBIS eliminates the labor-intensive task of one-at-a-time ingredient mixing, ensuring swift and efficient deployment of remediation amendments. By mixing inline, IBIS eliminates batch tank mixing, further accelerating the process. The result? Faster amendment changeovers, quicker setup and teardown, and unparalleled production efficiency save time and money on your remediation project.

Improving Accuracy

IBIS improves remediation application accuracy. By automating dosing control and mixing of amendments, IBIS minimizes variability, ensuring precise matching to remediation design specifications. By providing real-time data, IBIS supplies accurate application information, eliminating human error and enhancing data reliability. IBIS can be programmed to deliver depth-discrete dosing based on contaminant mass-flux, setting a new benchmark of automated capability for in situ remediation.

Enhancing Safety

IBIS enhances onsite safety through automation, mitigating amendment handling and spill risks. With reduced material handling and elimination of large-volume batching, IBIS minimizes spill and containment measures, safeguarding both personnel and the environment. Automated safety controls maintain programmed operating pressures, while quieter operations reduce noise abatement requirements, creating a safer and more conducive work environment.

Compact and Efficient

IBIS eliminates the need for space consuming batch tanks, using a compact design that connects directly to bulk reagent containers and a water supply. By reducing the footprint of remediation setups, IBIS optimizes space utilization without compromising performance. It is easily moved between onsite treatment areas, reducing operational downtime.

Empowering Onsite Personnel

IBIS liberates application personnel from rote manual labor, allowing our remediation scientist greater focus on amendment delivery and placement validation. With automated batching capabilities, IBIS maximizes efficiency and productivity, driving superior outcomes in the field.

Unparalleled Data Access

IBIS empowers with real-time data acquisition. With higher frequency data collection and instantly downloadable automated data, IBIS delivers unparalleled insights for improved analysis. IBIS prevents human error, eliminating manual entry while ensuring data integrity and reliability at every step during an injection project.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español