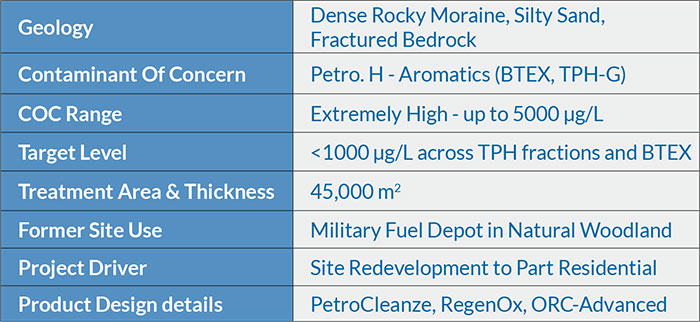

Large Scale Petroleum Hydrocarbon Plume Contamination

Summary

- An extensive area of groundwater under forest and disused commercial property is impacted with fuel due to a large historic spill incident.

- Pilot trials of RegenOx® and ORC Advanced® resulted in a 95-100% reduction of the Petroleum Hydrocarbon contamination in the aquifer.

- Due to this success, regulatory approval was given for the first phase of remediation in autumn 2013. Phase II started in 2015 and site closure is expected in 2017.

Introduction – Contamination Incident and Previous Strategy

RGS 90 has been commissioned to undertake the remediation of a former large military fuel depot. A number of pollution events had been recorded during its 40 years use. The largest was an explosion in 1958, where 14,000 m3 of petroleum products were released with around 6,000 m3 reaching the wider environment. An initial proposal provided by the problem holder consisted of biosparging and chemical oxidation using more than 1 million litres of hydrogen peroxide. RGS 90 approached REGENESIS with concerns regarding the inherent environmental and H&S risks, as well as its validity due to the low permeability and heterogeneity of the site.

An Alternative Strategy – The Benefits of Pilot Trials

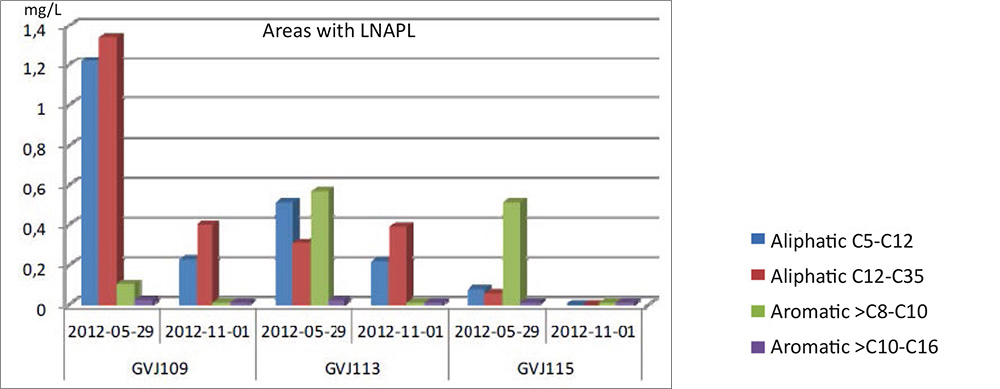

REGENESIS supported RGS 90 in designing an alternative strategy including pilot trials. Two separate pilot studies were completed on the site; one in areas of higher contamination where some Light Non-Aqueous Phase Liquid (LNAPL) was suspected to exist within fractures in the bedrock, was treated with three application rounds of RegenOx.

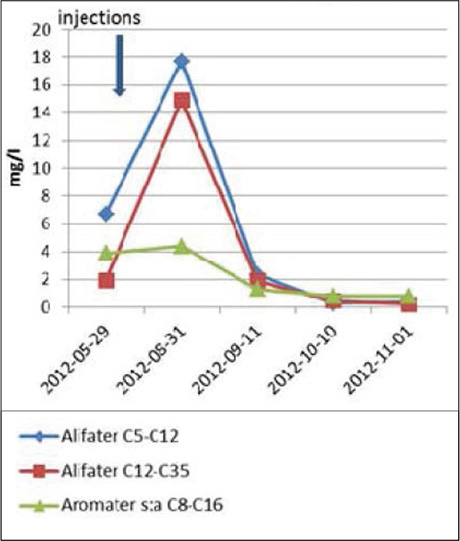

RegenOx is designed to chemically oxidise high concentrations of organic contaminants safely and without excess heat and pressure being produced. The second pilot study was completed using ORC Advanced in order to trial the treatment of parts of the site impacted with dissolved phase petroleum hydrocarbon contamination only. The application of ORC Advanced would create and sustain strongly aerobic conditions for up to 12 months from a single injection in order to accelerate the natural attenuation of the petroleum hydrocarbons within the groundwater.

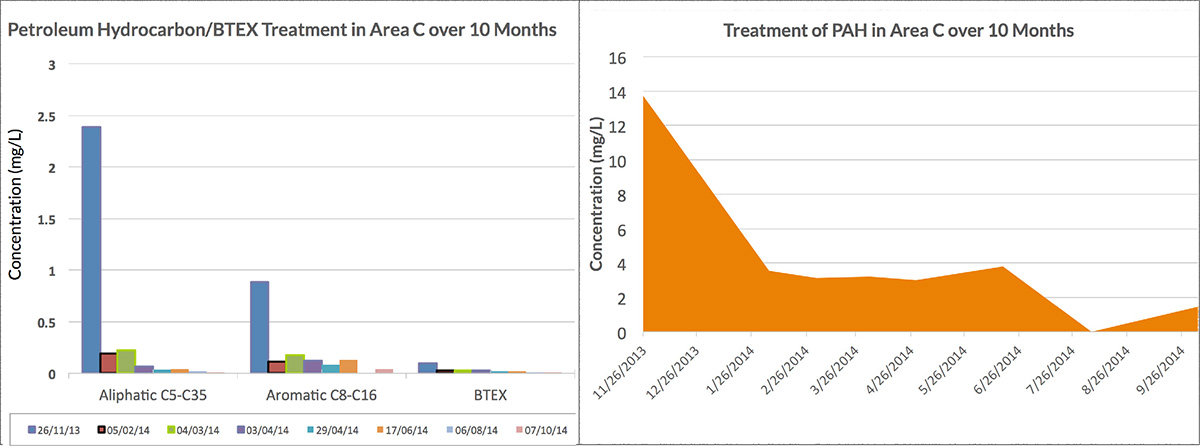

Fig. 2 Results from ORC Advanced area showing concentrations in 3 of the monitoring wells before and after treatment

Pilot Trial Results

In the RegenOx pilot trial area, a dramatic reduction in contaminant concentrations were seen due to in situ chemical oxidation (ISCO), with further degradation occurring through biological degradation of the partially oxidised residual contamination. In areas where adsorbed contamination or LNAPL was encountered, the analysis showed dissolution of the contaminants into the groundwater where they were then rapidly degraded, see Fig.1 for an example of this. In the second pilot study area, a single application of ORC Advanced was made across an area approximately 10 m by 10 m. As can be seen in Fig. 2, significant reductions in the dissolved phase contamination were achieved within a few months, with the technology still actively promoting the biological degradation of any residual contamination

The results from the pilot trials allowed RGS 90 to successfully prove that the use of ORC-Advanced and RegenOx would be successful in remediating the extensive TPH contamination across the site. The results assured the problem holder and regulators that this would be the most economical, technically viable and effective integrated remedial solution at the site. The data gathered from this pilot trial also allowed RGS 90 and REGENESIS to refine the proposed full-scale treatment of the wider plume.

Working in challenging conditions: pilot trial in the dense forest of Site Area C

Design Approach and Planning

It was determined that the main remediation project would then be completed out in two phases. Phase I comprised treatment of the smaller up-gradient site Areas C & D, followed a year later by Areas A & B in Phase II. Prior to the remediation works beginning however, an array of monitoring wells were installed on a 20 m by 20 m spacing in order to give a better delineation of the plume and the contaminant concentrations within it. These would then form the validation array to monitor the performance of the treatment. The intention was to treat the levels of contamination with the most appropriate remediation technology; areas with small amounts of LNAPL would be treated with RegenOx and then ORC Advanced. Areas with a high dissolved phase concentration only would receive a high dose of ORC Advanced and areas with a low dissolved phase concentration would be treated with a lower ORC-Advanced dose. The dose response would then be reviewed in order to further increase the accuracy of the remediation design for the larger Phase II works programmed for the following year.

Working in challenging conditions: pilot trial in the dense forest of Site Area C

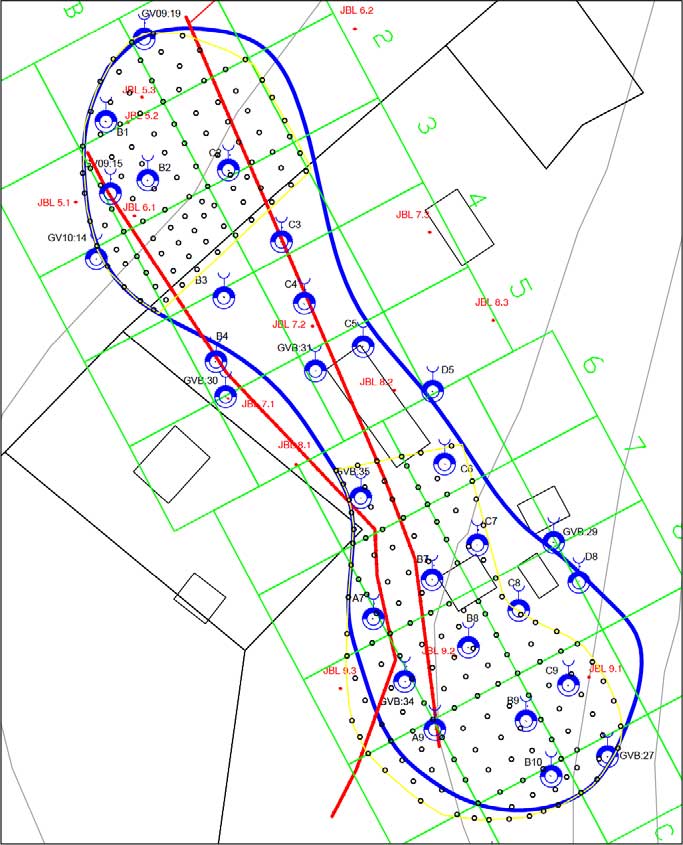

Phase I – Enhanced Aerobic Natural Attenuation

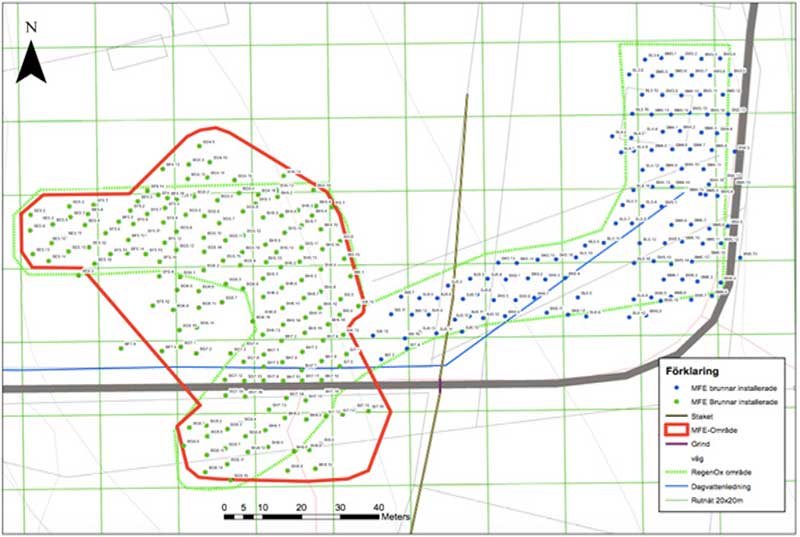

Throughout the winter of 2013/2014, ORC Advanced was injected into Areas C & D using direct push injection. The specific dose was tailored to the contaminant concentrations across the target area in order to provide the most accurate and cost effective treatment. Injection was completed into 257 points, see Fig. 3. RGS 90 devised a specialised method of drilling through the boulders encountered in the subsurface and injecting into the surrounding saturated sediments. The application was finished in only 8 weeks, with remediation then continuing over a period of 12 months with no further activities required beyond validation monitoring.

Within 10 months, the application achieved over 95-99% reduction (non-detect in some locations) in contaminant concentrations across the majority of the site (see Fig. 4 and 5). 28 out of 30 validation wells reached compliance levels, with the two remaining wells reaching close to target levels. The two non-compliant wells have shown reducing concentrations over time, but their performance is indicative of being on the edge of an effective treatment zone. Some small applications of ORC Advanced are planned in these two areas in spring 2016 in order to push them beneath the target concentrations.

Fig. 3 – DP locations in Areas C & D

Phase II

While the remediation of the Phase I area was underway; in the Phase II Area the drilling and installation of a 20 m by 20 m validation grid of 90 wells was completed. Greater amounts of measurable LNAPL were encountered than had previously been expected.

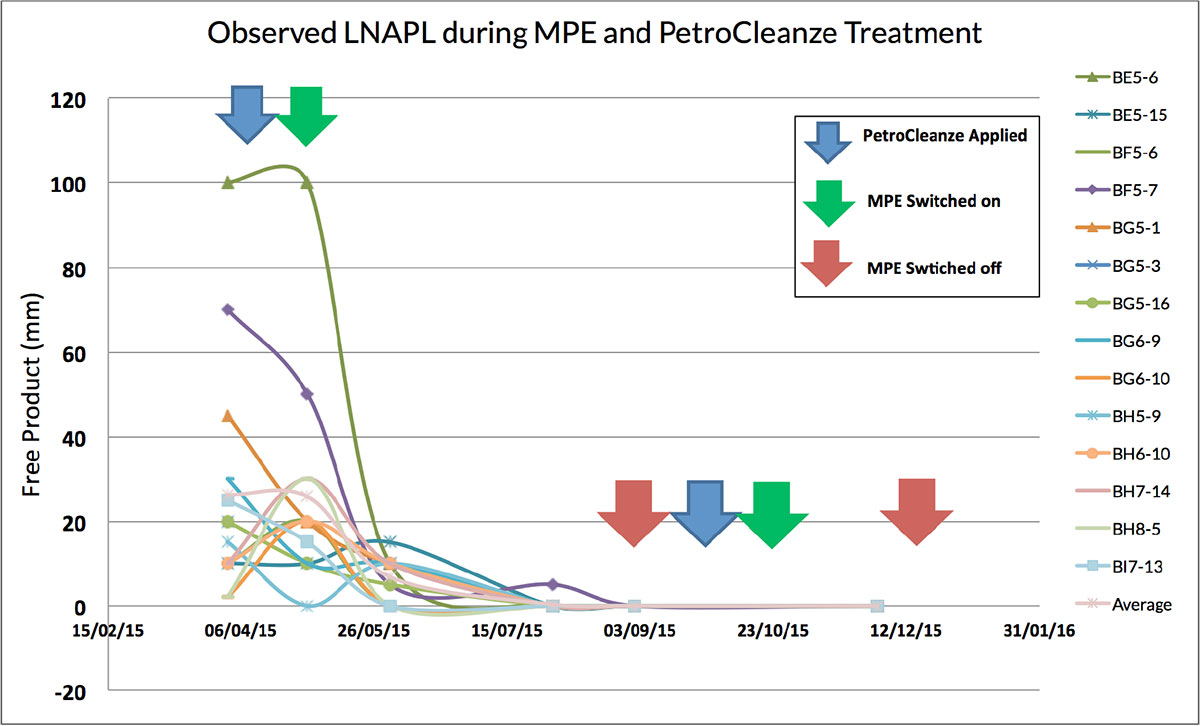

This area of free product was further delineated when the injection grid of approximately 300 wells was completed. In an area encompassing 172 wells, the remedial approach in this area was switched to Multi-Phase Extraction (MPE), using PetroCleanze to increase the effectiveness of the treatment. Fig. 6 shows the MPE area.

PetroCleanze is an inorganic surfactant that produces a temporary desorption of soil bound contamination within a physical extraction target area, resulting in a greater amount of mass being removed. This increases the effectiveness of MPE system, allowing it to be operated for a shorter period, with greater certainty that the adsorbed contamination (smear zone) will be depleted, reducing potential rebound due to desorption.

PetroCleanze was applied across the target area and the MPE system switched on to remove the desorbed contamination. The process was repeated on a smaller, more targeted area and all measurable free product was removed within 5 months, see Fig. 7. The system was switched off over winter due to the extreme cold. Sampling is due in Spring 2016 and the system may be switched on should any residual hotspots remain, or treatment moved directly on to ORC Advanced application in order to enhance the natural attenuation of the residual dissolved phase contamination.

In the Phase II areas immediately surrounding the augmented MPE treatment, contaminant concentrations were high, but there was no measurable free phase. Here, two ISCO campaigns have almost been completed using RegenOx to rapidly and safely break down the high levels of fuel in the groundwater and in the smear zone. These were stopped during the winter of 2015/2016 due

to the weather conditions. In Spring 2016, the injections will be completed and transition to enhanced biological degradation using ORC Advanced across the entire area will commence. This will target the residual dissolved phase contamination in order to reach the low remediation target levels.

Fig. 6 – MPE Area

Fig. 7 – MPV and PetroCleanze Treatment Results

Benefits of Appropriate Integrated Remedial Approach

Throughout the project, a considered, staged approach has been taken, allowing for the most appropriate and cost effective remediation technologies to be chosen throughout the programme and across the site. The application of these technologies has been optimised through further site investigation and pilot study performance. The projected cost of integrated technology application was calculated at between 25 – 55% of the cost of any of the same technologies used alone, representing cost savings of between £1.1 M – £4.5 M on the overall project. The projected time for completion was also shortened by several years, with site closure expected by 2017. Despite difficult conditions, the works are being completed effectively, with no excavation required; the remediation has left no visible impacts; important both for aesthetics, military security, and macro-environmental impact. Crucially, the forest has been left untouched.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español