RegenOx® Injected Into Frozen Permafrost at Alaska Site

Seasonal Access and Remote Location Require Unique Remediation Plan at Service Station

Project Highlights

- Sensitive ecosystem and limited seasonal accessibility required a unique remediation plan design.

- RegenOx® injected into frozen permafrost.

- Overall remediation plan requires three applications while site is accessible in summer months.

Project Summary

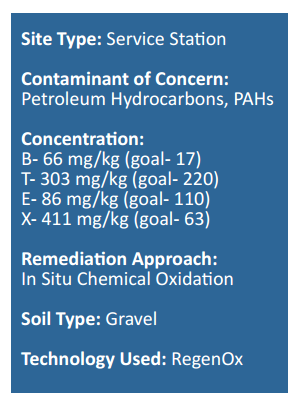

Located in Deadhorse, Alaska, this service station site was contaminated through multiple releases from the diesel and gasoline tanks. When this lease site was originally bid, it was required to be constructed with a minimum of 5 feet of gravel on the pads to protect the tundra. This lease requirement remains today.

The remote location on the North Slope of Alaska made it challenging to design, plan, and implement a remediation plan considering the temperatures were just above freezing. The area can only be accessed seasonally for monitoring/application and shipping products to the site proved to be a challenge. Located in a very sensitive native ecosystem (tundra/permafrost), in situ chemical oxidation (ISCO) was chosen as the remediation approach to avoid enlarging the plume.

Overall treatment goal for the project is to reduce hydrocarbon concentrations in approximately 365 cubic yards of source area soil to below cleanup levels. Treatment will be conducted in multiple phases and this project summary will summarize steps taken within the first year to address one-third of the exceedance area.

Remediation Approach

Surface soil to down to one-foot below ground surface was removed and stockpiled before subsurface soil from (1-5 feet below ground surface) was treated via in situ soil mixing using RegenOx®. Based on the effectiveness of Year 1 treatment; the plan is to use the same treatment method on remaining soil in subsequent years.

For the 125 cubic yards (or 1/3 of contaminated soil at the site), a total of 3,430 pounds of RegenOx (2,500 pounds of RegenOx Part A and 930 pounds of RegenOx Part B) were applied to treat BTEX, TPH, and naphthalene concentrations. Due to the sensitive and remote nature of the site, the application was staggered and the methodology was ultimately modified to prevent oversaturation and reduce the risk of plume migration. The Part B was mixed with a small amount of water and then applied and mechanically mixed thoroughly into the treatment area, followed by the Part A being applied dry and then well-mixed over the same area.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español