LNAPL Remediation in a Chalk Aquifer under a Residential Property

with BRD Environmental Ltd

Introduction

After completion of the redevelopment of former industrial land into residential properties, significant Total Petroleum Hydrocarbon (TPH) contamination was discovered in the groundwater and smear zone under the gardens and parking area. The TPH comprised diesel and heating oil, with up to 40mm of Light Non- Aqueous Phase Liquid (LNAPL) evident in the monitoring wells.

The original source of contamination (an above-ground storage tank) was removed during redevelopment; however, residual contamination had migrated into a lower chalk aquifer and after the discovery of LNAPL present within chalk fissures above the water table, remedial action was required.

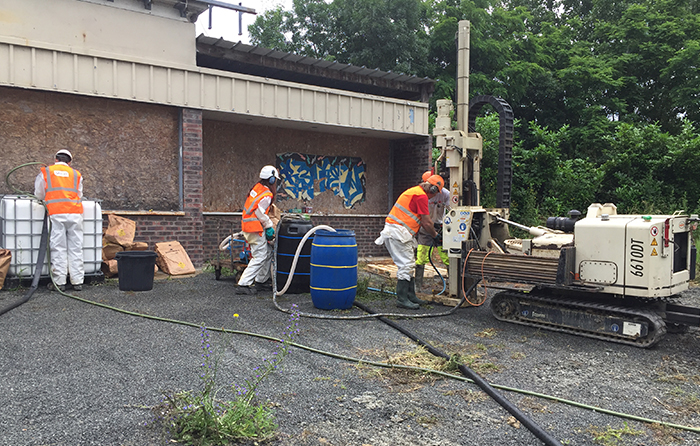

Figure. 1 On site RegenOx® injections using a direct push injection rig

Figure. 2 Total TPH Concentration in Boreholes BH13 and BH14

Method

The two most highly contaminated boreholes, BH13 and BH14, were located in a back garden and a car parking space. As space was restricted and to minimise the impact of works on residents, an in situ remedial technique was deemed the only viable option.

RegenOx® is an In Situ Chemical Oxidation (ISCO) reagent capable of treating high concentrations of a broad range of soil and groundwater contaminants including both petroleum hydrocarbons and chlorinated solvents.

The alkaline nature of RegenOx enabled its use within the chalk aquifer without adverse matrix reaction.

The ability of RegenOx to deal with both LNAPL and dissolved phase contamination avoided the use of ‘pump and treat’ equipment onsite. This minimised both operational and disposal costs and negated the requirement for bulky equipment on the site. Applications were completed using a small direct- push injection rig (Figure 1). This meant that the resident’s parking area could be reinstated at the end of each working day, so that they could park overnight as usual.

The RegenOx injections were completed in three events at two week intervals during June and July.

Results

A 99% reduction of TPH concentrations occurred rapidly in boreholes BH13 and BH14 following the injection works, with LNAPL no longer observed on the site.

Conclusion

A short campaign of RegenOx applications at the site completely removed any LNAPL and reduced TPH concentrations by 99% in a chalk aquifer and regulatory closure was achieved within a short period.

At £55,000 for the product and application work, the project was extremely cost effective, avoiding the use of operational and disposal costs on the site. The in situ nature of the works avoided disturbing or inconveniencing residents living on the site.

ISCO and Bioremediation at Former Petrol Station, Pays de la Loire, France

Under a former petrol filling station in the Loire Valley, in France the soil and groundwater was found to be contaminated with petroleum hydrocarbons (primarily BTEX). An integrated in-situ remedial solution has been put in place by a specialist remediation contractor, consisting of 26 PersulfOx injections in the source zone for fast and effective treatment of the most impacted soils and groundwater. ORC Advanced was also applied in the source zone to achieve long term in-situ bioremediation of any remaining petroleum hydrocarbons. In addition, an ORC Advanced barrier has been installed in the downstream plume area, to prevent off-site migration of the contamination.Read More

Remediation of PHCs and VOCs at a Former Dry Cleaner Site Using RegenOx®, ORC Advanced®, and ORC® Filter Socks

Former Dry Cleaning Site Redeveloped to Serve as New Home to Non-Profit Serving Homeless in Chilliwack B.C. Area

Project Highlights

- Introduction of RegenOx® and ORC Advanced® following in situ treatment using PulseOx1 resulted in the reduction in the initial concentrations of PHCs and dry cleaning chemicals in a sand and gravel aquifer, meeting site remediation goals

- Upon completion of remedial efforts, the project was awarded three British Columbia Ministry Environment instruments

Project Summary

A building occupied by a former dry cleaning business (1960s) located in Chilliwack, British Columbia was acquired by Ruth & Naomi’s Mission, (www.ranmission.ca) a non-profit organization serving Chilliwack. Environmental investigations to support the redevelopment of the former dry cleaner building revealed contamination of the soil and groundwater beneath the site and the offsite alley with petroleum hydrocarbons (PHCs) and dry cleaning related chemicals. Since the remedial excavation onto the offsite alley was not considered to be practical, RegenOx, along with ORC Advanced, was utilized for the in situ treatment of soil and groundwater within the excavation to reduce the remaining PHC and dry cleaning chemical concentrations.

Following treatment with RegenOx, reduction in the concentrations of PHC and dry cleaning related compounds were observed in soil and groundwater samples. RegenOx was additionally injected within the alley to treat the offsite plume. As a result, all post-remediation concentrations are below the applicable commercial land use standards. Additionally, ORC socks were applied to assist natural attenuation of any residual contaminants in groundwater. The successful investigation and remedial effort received three British Columbia Ministry of Environment instruments and now safely serves as a resource center and shelter.

Concentrations

- Volatile Petroleum Hydrocarbons VPH (up to 3,400mg/kg)

- EPH10-19 (8,200 mg/kg)

- Ethylbenzene (33mg/kg)

- Total Xylenes (160 mg/kg)

- Perchloroethylene (7μg/g)

- Trichloroethylene (2.8 mg/kg)

- VPHw (110mg/L)

- LEPH (5.6 mg/L)

- Ethylbenzene (2.14 mg/L)

- Toluene (2.7mg/L)

- Naphthalene (410μg/L)

- Perchloroethylene (2.76 mg/L)

- Xylenes (6.78mg/L)

- Vinyl Chloride (349 μg/L)

Technology Description

RegenOx is a percarbonate-based in situ chemical oxidation technology that rapidly destroys petroleum hydrocarbons and chlorinated contaminants through powerful chemical reactions. It directly oxidizes contaminants while a catalytic component generates oxidizing free radicals to destroy the target compounds.

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegredation.

ORC Filter Sock is a permeable filter sock containing calcium oxy-hydroxide based chemical which produces a controlled release of molecular oxygen (17% by weight) when hydrated.

Results

PHC and dry cleaning compounds were reduced in concentrations to groundwater standards following the application of RegenOx and ORC Advanced, facilitating the redevelopment of the former dry cleaning business to house the not-for-profit homeless shelter, Ruth and Naomi’s Mission, serving the Chilliwack, B.C. community. Upon completion of investigation and remedial efforts, the project was awarded three British Columbia Ministry Environment instruments. Up to 200+ homeless are served dinner daily by this organization which provides both shelter and recovery programs to men and women, assisting them in their reintegration into the community and work place.

1 PulseOx is a registered trademark of APT Water, Inc.

ISCO and Enhanced Aerobic Bioremediation during Residential Development

Excavation works minimised through the use of RegenOx, ORC-Advanced and ORC-Advanced Pellets, allowing development to continue without interruption.Read More

REGENESIS Remediation Services’ Efficient ISCO Treatment Keeps Redevelopment Schedule of Former Gas Station On Track

Project Highlights

- Three distinct zones of contamination effectively treated by in situ chemical oxidation (ISCO) and enhanced aerobic bioremediation

- Benzene (BTEX) concentrations in groundwater reduced by >99% within three months, achieving site goals for Low-Threat Closure (LTC)

- The treatment, design and application efficiency provided by REGENESIS® Remediation Services allowed the redevelopment schedule to be maintained

Project Summary

Operations at the site of a former gas station in San Jose, California resulted in contamination of the subsoil and groundwater with benzene. Following demolition of the station after 15 years of operation, the site was approved for redevelopment into a commercial property. However, the site failed to meet the groundwater criteria of the Low-Threat Underground Storage Tank Case Closure Policy (LTCP) for benzene (<3,000 μg/L) concentrations, and remediation activities were quickly undertaken in order to maintain the schedule for site redevelopment.

A remediation plan was developed by REGENESIS® that utilized in situ chemical oxidation and enhanced aerobic biodegradation to address the residual petroleum contamination at the site. Due to the extended drought in the area that caused rapidly declining groundwater levels, three separate zones of contamination were targeted in the remediation plan: the groundwater zone and two newly-formed vadose zones that are separated by a low-permeability unit. The 3700 ft2 treatment area included full coverage by the groundwater treatment as well as two distinct regions of the shallow and deep vadose zones.

A bench test using soil and groundwater from the site was performed to verify the effectiveness of the planned course of treatment prior to full-scale application. A >99% reduction in benzene concentrations confirmed the remediation plan, and application of the remediation chemistry was performed by REGENESIS Remediation Services (RRS) over two injection events. Due to the prolonged drought in the area, recycled water was brought on site for use in the field activities. The two injection events were separated by one month and each spanned ten days. During the first event, PersulfOx® was applied via direct push technology to 54 injection points. In the second event, ORC Advanced® was co-applied with PersulfOx through 59 points.

Technology Description

PersulfOX is a sodium persulfate-based chemical oxidation technology that destroys both hydrocarbon and chlorinated solvent contaminants in the subsurface. PersulfOx contains a built-in catalyst that activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegradation.

Results

Three months after treatment of the site was completed, BTEX concentrations decreased by over 99% from the baseline concentrations of 3070 μg/L. Furthermore, concentrations of all contaminants have been reduced to below the criteria for Low Threat Closure, and as a result of this rapid achievement of site goals, the redevelopment schedule of the site has been preserved.

Pilot Test of ISCO Soils Treatment in Industrial Area, Italy

At a former oil refinery in Italy, leaks from several large Aboveground Storage Tanks (ASTs) had caused the soil to become impacted with fuel. Concentrations of up to 3,000 mg/kg of petroleum hydrocarbons were measured in the unsaturated soil within the immediate vicinity of the ASTs. Read More

Combined PlumeStop® and ORC-Advanced® Treatment Remediates Low Level Benzene Contamination

Project Highlights

- Persistent benzene contamination reduced from 530 μg/L to 4 μg/L

- Target Medium Specific Concentration (MSC) achieved within one quarter of treatment

- Application of PlumeStop® and ORC Advanced® successfully completed by REGENESIS® Remediation Services (RRS) within three days allowing for the project

Project Summary

Operation activities at the site of an active gas station resulted in contamination of the groundwater with low levels of benzene. The concentration of benzene fluctuated, reaching 530 μg/L before remediation efforts were undertaken. REGENESIS designed a remediation plan to address the persistent low levels of benzene that combined the application of PlumeStop and ORC Advanced for in situ sorption and enhanced aerobic biodegradation.

The sorbent properties of PlumeStop make it possible to successfully treat low contaminant levels by creating local areas of high contaminant concentration that can then be colonized by contaminant-degrading bacteria. This co-localization of the contaminants and bacteria on the PlumeStop surface greatly improves the contact between the two components, thereby enhancing the speed and efficiency of the degradative reactions. Addition of ORC-Advanced further supports aerobic biodegradation by providing a long-lasting oxygen source.

RRS injected PlumeStop and ORC Advanced into 12 points around MW-6R (Fig. 1) that showed elevated benzene levels. A total of 1,200 lb of PlumeStop were first injected via direct push technology followed by injections of 240 lb of ORC Advanced into the same 12 holes. Treatment of the site was completed over the course of two days without any complications.

Technology Description

PlumeStop Liquid Activated Carbon (LAC) is an innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation.

ORC Advanced is a proprietary formulation of food-grade, calcium oxyhydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegredation.

Results

In the first quarterly sampling event after the remediation chemistries were applied, benzene levels had dropped from the pre-application level of 530 μg/L to below the Medium Specific Concentration (MSC) of 5 μg/L set by the Pennsylvania Department of Environmental Protection. Furthermore, groundwater quality parameters in MW-6R indicated good distribution of the remediation chemistry through the subsurface and the establishment of optimum parameters for continued aerobic biodegradation.

Innovative Application of PersulfOx Addresses BTEX Contamination at Former Gas Station Site

Project Highlights

- Innovative remediation plan designed by IRSL to address hydrocarbon plume using PersulfOx® addresses migrating plume

- Cleanup criteria on site was reached with only two injections of PersulfOx

- Direct Push Technology using PersulfOx counters any back diffusion

Project Summary

An active gasoline station in southwestern Ontario exhibited a hydrocarbon plume, which was migrating off site toward commercial buildings, presenting liability concerns for developers. Previous remediation efforts using other oxidants, including base-activated persulphate, did not result in significant reductions, and rebound was a problem, including pH buffering. InSitu Remediation Services, Ltd. (IRSL) was the consulting firm hired to perform the remediation work.

Led by Rick McGregor, IRSL designed an approach that included REGENESIS’® PerfulfOx to address the concentrations in the plume including BTEX ~ 25 mg/L, F1 ~29 mg/L, and F2 ~ 1.5 mg/L. The geology was silty sand with sand lens and a unconfined aquifer. The client’s cleanup goals were F1 0.75 mg/L and F2 0.15 mg/L. Two injections of PersulfOx using Direct Push Technology (DPT) were applied, targeting the sand lens and providing enough mass to allow for diffusion of PersulfOx into the silty sand to counter back diffusion.

Technology Description

PersulfOX and PersulfOX SP promote the rapid and sustained in situ oxidation of a wide-range of organic contaminants. As an advanced in situ chemical oxidation (ISCO) reagent, it destroys organic contaminants found in groundwater and soil through abiotic chemical oxidation reactions.

This turn-key, all-in-one product with a built-in catalyst activates the sodium persulfate component and generates contaminant-destroying free radicals without the costly and potentially hazardous addition of a separate activator. The patented catalyst enhances the oxidative destruction of both petroleum hydrocarbons and chlorinated contaminants in the subsurface.

With the purchase and proper use of PersulfOx Catalyzed Persulfate, clients gain the benefits of the latest advancements in persulfate technology for environmental remediation. PersulfOx SP was formulated for use on projects specifying the use of persulfate and a separate chemical activation process such as alkaline activation, hydrogen peroxide activation, or iron activation. It can also be used as a follow-on treatment to REGENESIS’ PersulfOx Catalyzed Persulfate technology.

Results

Following the two injections of PersulfOx using direct push technology, cleanup criteria was reached quickly, resulting in two-plus years of sublevel monitoring.

About InSitu Remediation Services

One of Canada’s most experienced remediation companies, InSitu Remediation Services Ltd. (IRSL) has designed, implemented, and maintained soil and groundwater remediation programs in diverse geological environments in North, Central, and South America, Europe and the Middle East. The company offers remediation support services and specializes in ensuring the most efficient use of technical and financial resources, managing shortened remedial time-frames, and mitigating unnecessary technical and financial risk.

Rick McGregor, B.Sc. Geology, M.Sc. Hydrogeology, M.B.A., is president of InSitu Remediation Services Ltd. A respected environmental professional with over a quarter century in environmental assessment and remediation, he has designed and implemented remediation programs across the globe.

RegenOx® and ORC Advanced® Application Reduces BTEX , MTBE, and TBA Concentrations to Below MCL

Site closure granted.Read More

Single Application of ORC Advanced® Results in 87% Reduction of Contaminated Groundwater Plume

Project Highlights

- Size of contaminated groundwater plume reduced by 87% through extensive injection of ORC Advanced, applied using vertical and horizontal wells.

- Total BTEX >62.5ppm (mg/l) concentrations were identified prior to site treatment.

- Final round of ORC injections approved by Illinois EPA and LUST Program and is in-progress.

Project Summary

This site had been a carwash and retail gasoline station in an industrial-commercial area. During the removal of two (2) 6,000- gallon gasoline underground storage tanks (UST) and two (2) fuel dispensers, a gasoline release was reported to the Illinois Management Emergency Agency, based on impacted soil observed during the excavation. Contaminants for this gasoline release were Benzene, Toluene, Ethylbenzene, and total Xylenes (BTEX). The release resulted in groundwater contamination that encompassed the entire property, and extended slightly off-site, impacting three businesses. The area covered by the groundwater plume was approximately 1.5 acres. The size of the groundwater BTEX plume posed a significant challenge in site treatment.

Remediation Approach

In this instance, LandTech, Inc. implemented an Enhanced Aerobic Biodegradation strategy using ORC Advanced. This included 12,800 pounds of ORC Advanced, 7 pounds of Nitrate, and 1 pound of Phosphorous nutrients applied to the site via direct injection through 242 vertical wells to 16 feet below ground surface, and 1,065 feet of horizontal wells beneath the existing structures. ORC Advanced® is an engineered, oxygen release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils. ORC Advanced provides remediation practitioners with a significantly faster and highly effective means of treating petroleum contaminated sites.

Results

This site presented significant challenges due to the extensive levels of BTEX contaminants and the large area of groundwater contamination. After one round of injections and a monitoring period of 1 year, analytical results for the groundwater demonstrated the ORC injections have reduced the 1.5 acre BTEX groundwater plume by 87%. A second/final round, 1,350 pounds, of ORC Advanced injections have been approved by the Illinois EPA to address a few recalcitrant performance wells.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español