PetroFix Bulletins

Proven PFAS Remediation Technology Promises to Save DoD Billions

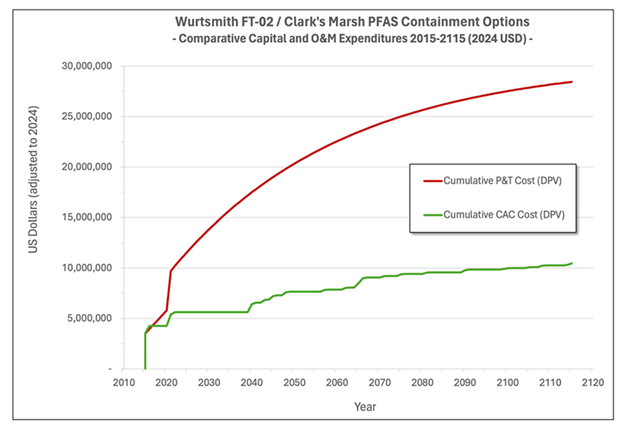

Published Research of Wurtsmith Air Force Base Shows Potential for Over 60% Savings

Too often the US Department of Defense (DoD) contractors default to the installation of pump and treat systems to mitigate PFAS pollution in groundwater. This approach has been proven inefficient and will not flush the aquifer free of PFAS. It serves only as a plume containment strategy. The use of in-ground colloidal activated carbon filtration (in situ CAC filtration) is a proven PFAS remediation approach. It presents a much more cost-effective and resilient solution, while avoiding the liability and long-term risk of PFAS waste. Where appropriate, in situ CAC filtration has the potential to reduce the DoD PFAS-related environmental liability by billions of dollars over the next 30+ years.

Recognized remediation experts Jeremy Birnstingl1, and John Wilson2 recently published a research paper entitled A Cost Comparison of Pump-and-Treat and In Situ Colloidal Activated Carbon for PFAS Plume Management3. The research discloses the high cost the DoD is paying to contain a PFAS plume at an existing DoD installation employing a typical pump and treat approach. Further, the paper compares the costs of operating the current remediation system with the costs of installing and operating an in situ CAC filtration system.

Key Takeaways:

- Pump and Treat will not flush PFAS from the aquifer – even after 100+ years of pumping.

- Over 60% Cost Savings – For the subject site, in situ CAC filtration was shown to be about 1/3 the cost of pump and treat systems over a 30-year period ($7.2M vs $19M)

Other Considerations:

- Zero Waste – Unlike pump and treat systems that generate hazardous PFAS waste, in situ CAC filtration generates no waste

- Reduces Risk and Liability – In situ CAC filtration eliminates the need to transport PFAS waste generated through public streets to a hazardous waste disposal facility and risking future liability

- No Energy or O&M Required – In situ CAC filtration effectively contains the PFAS plume while requiring no energy input or on-going operation and maintenance

- Jeremy Birnstingl, PhD, Regenesis, Bath UK

- John Wilson, PhD, Scissortail Environmental Solutions, Ada OK USA (formerly USEPA, Kerr Research Center, Ada OK)

- “A Cost Comparison of Pump‐and‐Treat and In Situ Colloidal Activated Carbon for PFAS Plume Management” © 2024, Authors Birnstingl, Wilson. Remediation Journal, Published by Wiley Periodicals LLC

Understanding PFAS Remediation Using Colloidal Activated Carbon

eBook highlights:

- Colloidal activated carbon (CAC) offers a low-cost, zero-waste PFAS solution

- CAC converts the subsurface into a purifying filter

- How does activated carbon adsorb contaminants and what primary factors govern sorption behavior?

- How does a CAC barrier contain PFAS over the long term?

This eBook delves into the mechanics of in situ remediation of per- and polyfluoroalkyl substances (PFAS) with CAC, explaining how this approach is used to prevent PFAS exposure risk. When applied directly into the subsurface, this patented CAC material effectively converts the subsurface into a purifying filter. Commercially available as PlumeStop® and SourceStop®, these technologies efficiently remove PFAS.

In situ filtration using CAC is increasingly gaining widespread attention as the environmental industry seeks practical and economically viable solutions to remediate PFAS-contaminated sites. With many known benefits, including low cost and zero waste, this approach to eliminating PFAS risk provides significant advantages, including avoiding the need for permanent infrastructure, ongoing operations and maintenance, external power, and the need for PFAS waste disposal.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español