February 2020 Newsletter

Client Spotlight: Kyle Hayes

Kyle Hayes is an Environmental Department Manager for Terracon Consultants, Inc. Although many of the projects he works on are similar in nature, each has a different set of circumstances and attributes that require looking through a different lens to determine the best path forward. He shares, “Each day brings new opportunities and challenges that require research, critical thinking, and problem solving.” Hayes continues, “Since Terracon’s environmental services are broad, my oversight and management activities mostly pertain to due diligence, site assessment, remediation, brownfields, regulatory compliance and permitting, asbestos, and industrial hygiene related projects.” Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

Combined Amendment Approach Using ZVI Successfully Treats Chlorinated Solvents

This case study reviews a formerly undeveloped site in downtown Jacksonville that was impacted with chlorinated solvents in the groundwater and metal-impacted soils. The site required remediation prior to moving forward with development. Ryan Companies US, Inc. was under contract to purchase the property from the site owner and was seeking an expedited closure of the site prior to completion of construction. To treat the chlorinated solvent groundwater plume, Terracon selected multiple technologies from REGENESIS, including PlumeStop, zero-valent iron (ZVI), Bio-Dechlor Inoculum Plus (BDI Plus), and Hydrogen Release Compound (HRC).

Webinar Recording Now Available

Land Science is pleased to present a webinar with vapor intrusion experts Dr. Blayne Hartman of Hartman Environmental Geoscience and Dr. Mark Kram of Groundswell Technologies. During this webinar presentation, they discuss updates regarding vapor intrusion pathway issues, including regulatory updates and the use of vapor intrusion continuous monitoring technology. They are joined by Tom Szocinski, CEP, Director of Vapor Intrusion at Land Science, who discusses technologies to mitigate vapor intrusion.

Upcoming PFAS Webinar – Sign Up Today!

In this webinar we are pleased to have as a special guest speaker Jack Sheldon, Senior Remediation Specialist at Antea Group, and Caron Koll, PG, LSP, and PFAS Lead at Antea Group. Their presentation will discuss lessons learned from a decade of experience working with PFAS contaminants in groundwater. Through more than a decade of developing sampling programs and interpreting PFAS analytical data, many lessons have been learned and this webinar will focus on a few of those lessons. This free webinar begins Wednesday, March 25th, 2020 at 11am pacific/2pm eastern.

New Battelle Sponsorship Opportunity

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

January 2020 Newsletter

Client Spotlight: Kyle Sorensen

Seeing projects come full-circle and reach closure is especially gratifying for Kyle Sorensen, Project Manager at Antea Group. He shares, “I’ve had the opportunity to work on chemical and manufacturing facilities, retail petroleum sites, and even sites in the beverage industry, among others. The variety has given me the opportunity to be involved in many different types of projects that have helped diversify my skillset. In addition, it’s allowed me to develop strong relationships with great people along the way.” With responsibilities that include managing remediation and compliance-related projects for a broad range of clients, Sorensen enjoys supporting clients through the entire remediation project lifecycle. Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

Innovative Approach Reduces Benzene to Achieve Closure

This case study reviews a gas station site in Greenville, Alabama where petroleum hydrocarbon contamination was present in the subsurface for decades. This site is part of an environmental liability transfer and Antea Group assumed the liability for this site. Antea Group required an effective remedial solution that would result in rapid site closure. Antea Group partnered with REGENESIS to create a remedial design using an in situ chemical oxidation (ISCO) treatment paired with an aerobic bioremediation technology to ensure a complete treatment of this site. PersulfOx, PlumeStop, and ORC Advanced were applied to quickly reduce benzene levels to non-detect, resulting in successful regulatory closure.

Webinar Recording Now Available

Land Science is pleased to present a webinar with vapor intrusion experts Dr. Blayne Hartman of Hartman Environmental Geoscience and Dr. Mark Kram of Groundswell Technologies. During this webinar presentation, they discuss updates regarding vapor intrusion pathway issues, including regulatory updates and the use of vapor intrusion continuous monitoring technology. They are joined by Tom Szocinski, CEP, Director of Vapor Intrusion at Land Science, who discusses technologies to mitigate vapor intrusion.

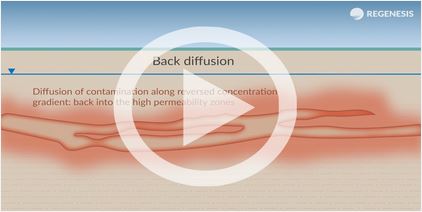

Back Diffusion Explained

Complex, heterogeneous sites can provide a challenge to the achievement of stringent remedial targets for groundwater contamination. The USA’s National Research Council (NRC) has identified back diffusion – also known as matrix back diffusion – as one of the prominent processes that limit our ability to clean up groundwater at those sites. This video explains the process of back diffusion and its effect on achieving remedial targets.

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

December 2019 Newsletter

|

Upcoming Events

|

February 2019 Newsletter

|

Questions?REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

|

January 2019 Newsletter

|

|

Questions?REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

|

December 2018 Newsletter

|

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español

Chad Northington

Chad Northington

John Hesemann, PE

John Hesemann, PE Craig Sandefur

Craig Sandefur

Steve Sliver

Steve Sliver

This video documents a beta-test of PetroFix at a petroleum bulk storage facility in the Midwest. Environmental consulting and engineering firm Patriot Engineering was tasked to develop a remediation approach to address dissolved phased petroleum-impacted groundwater caused by leaking underground and above ground storage tanks at the site. Steve Sittler of Patriot discusses the excellent results from the PetroFix application, eliminating contaminants one month post-injection, as well as signs that indicate biodegradation is occurring. Patriot believes that PetroFix is a viable remedial option for this site and is planning a full-scale application to successfully address the state regulatory agency’s request for compliance. View the case study video here.

This video documents a beta-test of PetroFix at a petroleum bulk storage facility in the Midwest. Environmental consulting and engineering firm Patriot Engineering was tasked to develop a remediation approach to address dissolved phased petroleum-impacted groundwater caused by leaking underground and above ground storage tanks at the site. Steve Sittler of Patriot discusses the excellent results from the PetroFix application, eliminating contaminants one month post-injection, as well as signs that indicate biodegradation is occurring. Patriot believes that PetroFix is a viable remedial option for this site and is planning a full-scale application to successfully address the state regulatory agency’s request for compliance. View the case study video here.

Due to past operations at a former solvent recovery facility, the soil and groundwater were contaminated with PFAS. PlumeStop, a cost-effective colloidal activated carbon technology, was applied in situ to rapidly adsorb the PFAS contaminants in the upgradient water onto the micron-scale activated carbon.

Due to past operations at a former solvent recovery facility, the soil and groundwater were contaminated with PFAS. PlumeStop, a cost-effective colloidal activated carbon technology, was applied in situ to rapidly adsorb the PFAS contaminants in the upgradient water onto the micron-scale activated carbon.

Groundwater contamination was caused by discrete releases of chlorinated solvents at a Rail Site in Quebec. A combined remedy approach using PlumeStop and AquaZVI was chosen because it allows for the highest treatment efficiency at the lowest possible cost. A pilot test was conducted in early November.

Groundwater contamination was caused by discrete releases of chlorinated solvents at a Rail Site in Quebec. A combined remedy approach using PlumeStop and AquaZVI was chosen because it allows for the highest treatment efficiency at the lowest possible cost. A pilot test was conducted in early November.

Blayne Hartman, PhD

Blayne Hartman, PhD Mark Kram, PhD

Mark Kram, PhD

and Institute of Environmental Health (IEH), at the <a href=) Oregon Health & Science University (OHSU)

Oregon Health & Science University (OHSU)

When it comes to honing one’s expertise within the environmental remediation industry, Richard Desrosiers, Associate Principal and Hydrogeologist at

When it comes to honing one’s expertise within the environmental remediation industry, Richard Desrosiers, Associate Principal and Hydrogeologist at