Plume Remediation at an Active Manufacturing Site near Orléans, France

The remedial works were completed in difficult working conditions; in a busy delivery yard, without disruption to existing site activities.Read More

Chlorinated Solvents Treatment at Former Dry Cleaner Site, UK

Excavation treatment and direct push application of HRC and HRC Primer, providing a reactive barrier at the down gradient site perimeter.Read More

Design Focused Remediation of a UK Defense Manufacturing Site

The remediation injection works, completed by REGENESIS between the demolition and construction phases, minimised impact on the site redevelopment programme.Read More

Active Manufacturing Plant, Cataluña, Spain

Chlorinated solvents treated with 3-D Microemulsion and HRC PrimerRead More

Successful Remediation of a Large Scale Chlorinated Solvent Plume

A single injection of 3-D Microemulsion on a wide injection grid remediates redevelopment site.Read More

Treatment of Chlorinated Solvents in Limestone Bedrock

A Barrier Treatment Demonstrates Longevity of 3-D MicroemulsionRead More

Bioremediation of Petroleum Hydrocarbons, Oxfordshire, UK

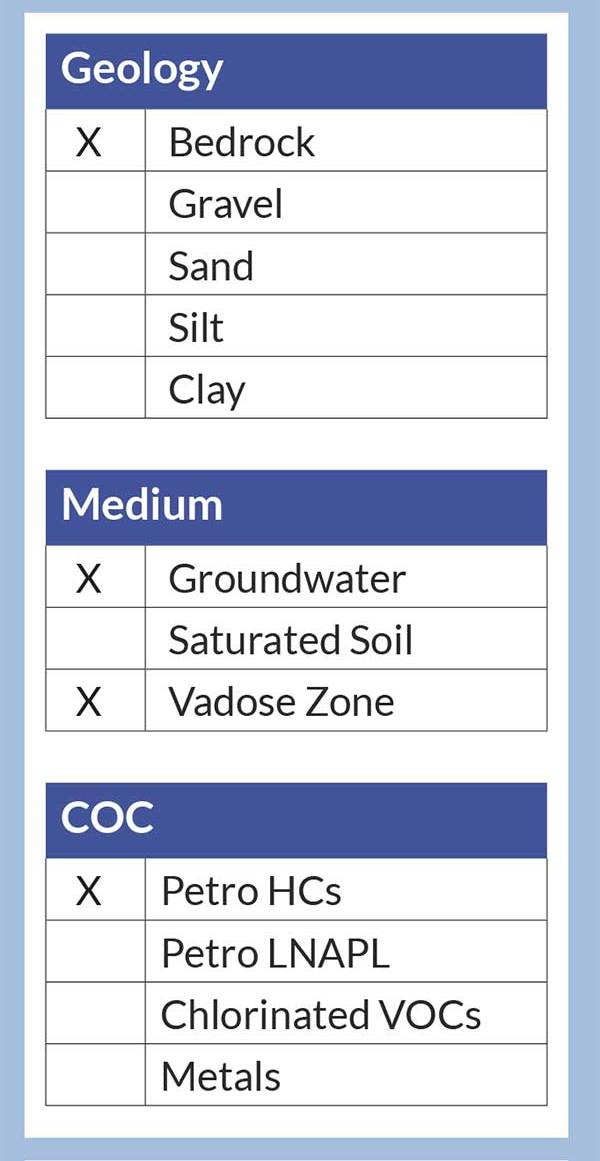

Summary

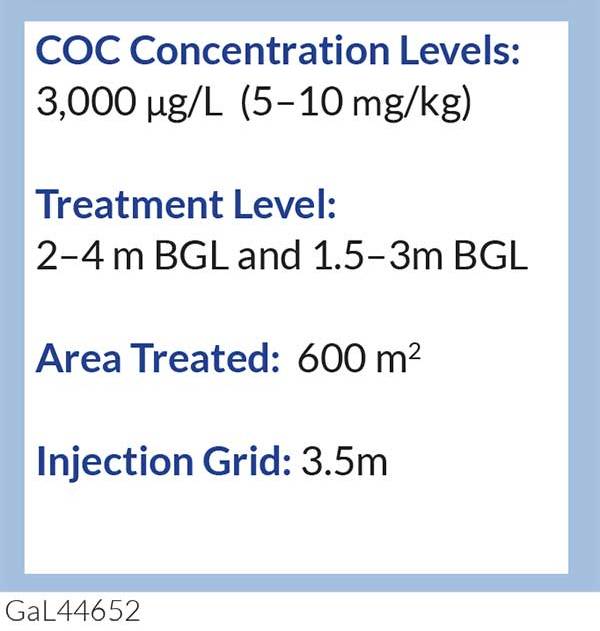

Following a site investigation (SI) and the removal of 8 underground storage tanks at a former petrol filling station, it became clear that the groundwater and soils beneath the site were grossly impacted by petroleum hydrocarbons (TPH). The geology comprised of made ground underlain by weathered limestone at 1m BGL. Though the groundwater concentrations were relatively low (3,000 μg/L TPH), the high sorbed mass in the soils (up to 10,000 mg/kg) was of concern. Though the remediation strategy did allow for the excavation and treatment of the weather material, due underground utilities most of the impacted material could not be excavated for health and safety reasons, without diverting the existing underground infrastructure.

REGENESIS and the Environmental Consultant formulated a remediation strategy comprising of partial excavation of impacted material (where allowed) and in-situ enhanced aerobic bioremediation of the groundwater for betterment of underlying conditions. All to be validated by groundwater monitoring to demonstrate contaminant mass reduction across the site.

Treatment

An ORC-Advanced® slurry was injected across 54 No. wells installed into the underlying bedrock with specific doses in the northern and southern areas of the site to target where TPH had been recorded during the SI. ORC-Advanced was applied across the entire plume, in order to provide enhanced aerobic biological degradation of the dissolved phase for 12 months from a single injection.

What’s Special?

- A remediation strategy where validation of the groundwater (not soil) achieved site sign-off, resulting in quick site closure.

- The in situ remediation allowed for injection adjacent to underground utilities without damaging them, avoiding the need for excavation or re-routing infrastructure.

Remediation at Active Petrol Filling Station in North Italy

Integrated treatment of petroleum hydrocarbons via enhanced physical extraction and aerobic bioremediation with PetroCleanze and ORC AdvancedRead More

In Situ Remediation of Petroleum Hydrocarbons in Deep Chalk

From LNAPL to less than 1,000 μg/L in seven months using an integrated treatment approach Read More

Petroleum Contaminated Groundwater Treatment, West London, UK

Installation of ORC-Advanced barrier successfully reduced the contaminant influx onto the site, allowing for site redevelopment without any disruption Read More

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español