Manufacturing Site Gets Closure using In Situ Desorption with Vacuum Enhanced Recovery for Petroleum Hydrocarbons

Project Highlights

- VOC levels show a 99% decrease in soil and 66% decrease in groundwater contamination

- Unique desorption reagent and enhanced recovery process approved for use by Michigan DEQ

- Site closure granted for two petroleum releases within same general area

Project Summary

Two separate UST petroleum releases were identified within the same general area of the manufacturing site with one being more recent and the other an older historic release. Following soil hydro-excavation activities which were limited by a building footprint, residual VOC contamination was identified at concentrations of 770,820 μg/kg in soil and 12,387 μg/L in groundwater. In Situ remediation using PetroCleanze® , an enhanced desorption/ extraction technology was planned for use to treat the remaining high levels of VOCs. Petro- Cleanze is optimized to desorb bound hydrocarbon mass and drive it from the soil matrix into the aqueous phase. Once pollutants are moved into the dissolved phase, its ability to chemically oxidize portions of the contamination coupled with enhanced recovery (physical extraction) effectively reduces contaminant concentrations.

Remediation Approach

A total of four initial PetroCleanze injection/extraction events took place in two treatment areas close to where the UST was once located. Each injection used a total of 1,320 lbs. of PetroCleanze and 925 lbs. of RegenOx Part A; the material was applied as a 5% solution (2000 gallons) through eight direct-push injection points. The vertical treatment interval ranged between 5 feet to 15 feet below ground surface. Following each injection, a vacuum enhanced recovery event was performed approximately two weeks later. The two week period was critical as it allowed PetroCleanze time to react and free up the bound hydrocarbon mass. Approximately 2,000 gallons of petroleum impacted water was removed during each extraction event and disposed of at a licensed disposal facility. Correlating soil samples in key treatment areas indicated that concentrations were reduced up to 99% with the exception of one area which required an additional injection event. Based on the site conditions, subsurface obstructions limited the influence of the PetroCleanze to this area. Therefore, a fifth injection event was conducted immediately surrounding the residual area in which the soil contamination remained to directly address the soil contamination. Correlating soil samples following the additional injection event indicated the concentrations were reduced up to 90%. Six months after treatment, groundwater VOC levels in EW-2 were reduced from 12,000 μg/L to 4000 μg/L marking a 66% reduction in the treatment zone. Within the same well, following each injection/extraction event, TPH data reported concentrations consistently decreasing from 20,000 μg/L to 10,000 μg/L to 5,900 μg/L. In 2014, as a result of the significant reductions in both soil and groundwater contamination, Michigan DEQ approved restricted UST closure for the two petroleum releases with no further action required.

Technology Description

PetroCleanze is a customized formulation of the widely used RegenOx in situ chemical oxidation technology. The primary function of PetroCleanze is to increase the desorption rates of hydrocarbons bound in saturated soil and make them available for more efficient and rapid treatment using a range of enhanced recovery technologies.

$150,000 Cost Savings Achieved using Enhanced Anaerobic Bioremediation and Bioaugmentation

Site Closure Pending for Treatment of TCE at Former Manufacturing Facility

Project Highlights

- Pilot test moved to full-scale application after rapid decrease in TCE and daughter product contamination

- Cost for ERD injection was approximately $70,000, compared to more than $250,000 for the proposed-permanganate ISCO injection

- A no further action request has been submitted to the regulatory agency and is being reviewed for closure

Project Summary

During due diligence for a property transfer at a former manufacturing facility in Indiana, TCE impacts in groundwater were discovered downgradient from a former above-ground storage tank (AST). Little to no TCE remained in the sandy soils within the source area but migrated into groundwater resulting in a plume extending off-site. An initial plan was proposed to address the TCE in groundwater via an in situ chemical oxidation (ISCO) approach using potassium permanganate. The consultant, KERAMIDA, believed this approach was overly aggressive, given the relatively low groundwater concentrations and lack of significant soil impacts. Also, the permanganate ISCO treatment was much more expensive and difficult to implement compared to a biological enhanced reductive dechlorination (ERD) approach. At the request of the regulatory agency, a pilot injection using 3-D Microemulsion® and BDI® Plus was performed in the source area and rapid reduction of TCE was observed within the first three months, accompanied by daughter product (cDCE and VC) production. Based on the results, the regulatory agency approved a full-scale injection one year later. Postinjection monitoring performed for two years following the full-scale injection indicated rapid decreases in TCE concentrations in all of the impacted wells with concurrent increases in daughter product concentrations. Daughter product concentrations also decreased significantly 9 months after 3-D Microemulsion and BDI Plus injection. At the conclusion of two years of post-injection monitoring, all of the wells in the treatment area were below the regulatory action levels for all compounds. A request for closure is currently being reviewed by the regulatory agency.

Remediation Approach

KERAMIDA developed a remedial plan that involved ERD and bioaugmentation, using 3-D Microemulsion and BDI Plus. The total cost for the injection was approximately $70,000, compared to more than $250,000 for the proposed permanganate ISCO injection. A total of 6,400 pounds of 3-D Microemulsion and 48 liters of BDI Plus were injected into 48 points spaced 15 feet apart in a grid pattern throughout the primary impacted area. The injection interval was approximately 9 to 18 feet below grade. The ERD/bioaugmentation approach saved more than $150,000 compared to the permanganate ISCO approach, likely more since the nature of ISCO as a contact-based remedial technology would likely have required multiple injections to achieve remedial goals.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

About the Consultant

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

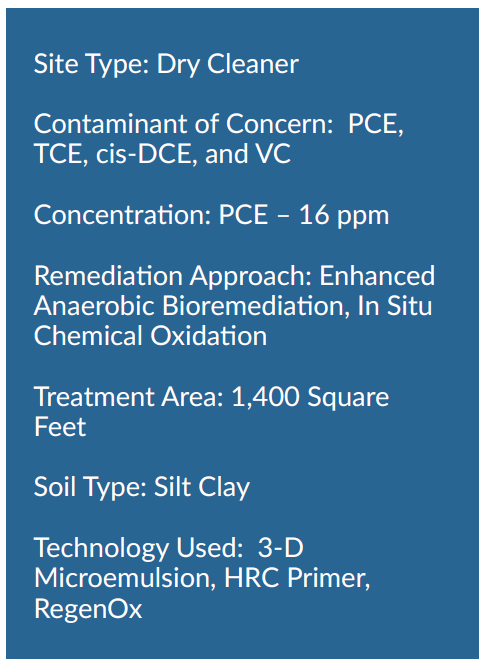

ERD Remediation Approach Replaces Permanganate Treatment in Low Permeability Soils

3-D Microemulsion® and BDI® Plus Treat PCE Contamination at Former Dry Cleaner

Project Highlights

- Previous remedial techniques included soil excavation and in situ chemical oxidation (ISCO)

- ISCO injection proved difficult due to low permeable soils so KERAMIDA developed an ERD/bioaugmentation injection design

- Reductions in PCE/TCE contamination observed in most wells within the injection area; monitoring is ongoing

Project Summary

The site was a former Indianapolis dry cleaner with historical releases of PCE to the subsurface. Previous remedial techniques included soil excavation in the source area, in an off-site, right-of-way area, and an in situ chemical oxidation (ISCO) injection using potassium permanganate. These approaches did reduce PCE concentrations in groundwater; however, they remained well above regulatory closure levels in multiple wells. After a almost two years of post-ISCO injection monitoring and evaluation, the consultant, KERAMIDA, recommended an alternative biological, enhanced reductive dechlorination (ERD) approach in the area of residual chlorinated impacts.

Remediation Approach

KERAMIDA worked with REGENESIS to develop an ERD/bioaugmentation injection design using 3-D Microemulsion® and BDI® Plus. The final design included 20 injection points spaced 15 feet apart on a grid pattern throughout the area of residual PCE/TCE impacts. The injection included a total of 1,200 pounds of 3-D Microemulsion and 18 liters of BDI Plus, distributed evenly over the 20 injection points with an injection interval of 10-13 feet below grade (targeting the impacted sand lens). The low permeability of the impacted sand lens, which proved problematic for the high volume of fluids needed for the permanganate ISCO injection, was a challenge. Since 3-D Microemulsion can be injected with minimal water when necessary, the low fluid volumes required to effect remediation proved to be ideal for this site. In addition, the low cost of the approach compared to other potential options, combined with the long-lasting effects of the remediation products provided a significant cost-to-closure savings. One year of post-ERD implementation (post-injection) monitoring shows PCE/TCE decreases and corresponding daughter product production (cDCE and VC). The persistence of strong anaerobic conditions resulting from the use of 3-D Microemulsion is expected to keep VOC concentrations and daughter products low well into the future.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product.

Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

About the Consultant

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

KERAMIDA Inc. is an engineering and consulting firm that serves industries, businesses, cities, and governments worldwide. They provide strategy and implementation services in: Sustainability, Green House Gases, Energy, Environmental Compliance, Remediation, Environmental Due Diligence, Brownfield Redevelopment, Plant Decommissioning, Health & Safety, Training, Risk Management, and ISO Management Systems. Established in 1988, KERAMIDA is headquartered in the historic Lockerbie Square district of Indianapolis, Indiana. The firm employs over 70 technical experts and support personnel in offices throughout the U.S., including Chicago, IL; Pittsburgh, PA; New York, NY; Los Angeles, CA, Sacramento, CA. KERAMIDA’s many principals have worked for over 25 years in the sustainability, environmental, health & safety, and remediation arenas, and are recognized leaders in their fields. Their engineers, scientists, and planners are renowned for delivering creative, integrated EHS solutions to a broad range of clients throughout the U.S. and abroad.

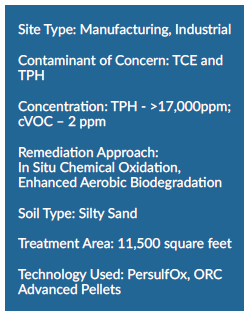

ISCO Treats High Levels of TCE with Planned Enhanced Bio for TPH Treatment

157,000 lbs. of PersulfOx® Applied to Treat Illinois Manufacturing Facility

Project Highlights

- Remediation mandated after oil sheen observed in river adjacent to manufacturing facility

- In Situ chemical oxidation (ISCO) paired with excavation to remediate site

- Tight treatment deadline met through supply of 51 PersulfOx SuperSacks, containing 2,204 lbs. each, which were delivered within a few days’ notice

- TPH soil plume has been reduced by >90% (from 6,111 cubic yards to 555 cubic yards)

Project Summary

An operating metal fabrication facility, located in Illinois, caused subsurface impacts from the use of cutting oils and degreasing solvents. This resulted in high levels of TPH and TCE in soil and groundwater. The state of Illinois cited the facility for a violation when an oil sheen was observed seeping from the property into an adjacent river. A mechanical oil recovery system was installed and absorbent booms were used to stop oil from reaching the river. ISCO was selected as the remediation approach to treat the contamination below the active facility. The TCE area was treated with PersulfOx via injection wells and a soil mixing application with an excavator.

Remediation Approach

Prior to the start of remediation activities, a change in the primary consultant was made and a new consultant was brought in. The new consultant imposed a tight deadline of several months to complete the full scope of remediation activities. REGENESIS was able to assist with keeping the project on-deadline through the timely delivery of 51 PersulfOx SuperSacks, containing 2,204 lbs. each. The PersulfOx SuperSacks were delivered within a few days’ notice. The consultant installed a series of injection wells within and outside of the building. PersulfOx was injected into these wells during three applications over a three-month period. Additionally, the TCE area was treated with PersulfOx® through a soil mixing application using an excavator. The final step of the remediation plan is to treat the TPH-impacted soils outside the building through excavation and the application of Oxygen Release Compound (ORC®) Advanced Pellets which will supply a long-term oxygen source of oxygen for enhanced bioremediation of the residual TPH. The client is also evaluating the use of PlumeStop to change the FOC value of the soil for a site specific Tier 3 closure level via MNA for an area that had extremely high TPH values >40,000ppm.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced Pellets are a pelletized version of REGENESIS’ widely used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications.

AZ Superfund Site Uses ISCO to Replace Recirculation Wells Leading to Cost Savings of $100,000

Project Highlights

- 95% reduction of BTEX, MTBE and TMBs reported on-site

- Total savings estimated to be $100,000

- In Situ Chemical Oxidation (ISCO) combined remedy design incorporates PersulfOx® to effectively address reduction in contaminants

Project Summary

A former industrial paint facility in Tempe, Arizona was contaminated with high levels of gasoline in the groundwater. Ongoing active remediation using Accelerated Remediation Technology (ART) was applied to treat high levels of BTEX, MTBE and TMB. However, this remediation approach was unsuccessful in reducing contaminants to cleanup target levels due to the limited radius of influence produced by the recirculation well system. REGENESIS was approached to design an ISCO plan using the existing treatment well infrastructure.

Remediation Approach

REGENESIS injected 10,028 pounds of PersulfOx at a 12% solution in two applications. As a result, a 95% reduction of BTEX, MTBE, and TMBs was reported post-application. The overall PersulfOx ISCO injection treatment totaled $40,000 – a small fraction of the previously deployed ART system cost and equal to four months of the ART system’s operational expense.

REGENESIS Solutions Applied

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

Results

The REGENESIS ISCO plan using PersulfOx contributed to the 95% reduction in BTEX, MTBE, and TMBs while providing significant cost savings to the client in the remediation of this Arizona Superfund site. Use of a combined remedy approach offers clients viable options for achieving cleanup target levels and compressed time to closure.

RegenOx® and 3-D Microemulsion® Injections Treat VOC Impacted Soils

PCE Contamination at Former Dry Cleaning Site in Northern California Remediated

Project Highlights

- PCE soil concentrations of up to 16,095 ug/kg in the hot spot area

- After initial ISCO application, ERD was used to continue VOC concentration reduction

- Latest sampling event reported concentrations below clean-up target levels

- No further remediation needed on-site

Project Summary

In 2007, VOCs including (PCE) and related compounds including (TCE), (cis-DCE), and vinyl chloride (VC) were detected in soil and groundwater samples collected at a site in Northern California. A comprehensive field investigation conducted under the Regional Water Quality Control Board identified a distinct VOC-impacted soil area behind the former dry cleaner. Site characterization work identified the presence of VOCs including PCE with soil concentrations of up to 16,095 ug/kg in the hot spot area. A combined technology remediation approach was

implemented on-site including injections of RegenOx®, 3-D Microemulsion® and HRC® Primer. At the most recent sampling event, approximately 2.5 years post-application, the maximum detected concentrations of PCE and related VOCs was 420 ug/kg and all soil sample results were below the Soil Cleanup Levels. These data suggest that the combination of in situ chemical oxidation (ISCO) with RegenOx, followed by enhanced reductive dechlorination with 3-D Microemulsion has been highly effective in reducing VOC concentrations in soil.

Remediation Approach

Three rounds of ISCO injections with RegenOx were applied on-site to treat the vadose zone soils. After the first round of injection, PCE was detected in soil samples collected in this area at maximum concentrations of 2,000 ug/kg, which, while substantially lower than initial concentrations indicated a need for further treatment. Enhanced reductive dechlorination (ERD) was performed by injecting 3-D Microemulsion and HRC Primer into vadose zone soil to treat PCE and related daughter products. The products were injected into 33 borings in the hot spot area with the treatment interval between 3 feet and 17 feet below ground surface. The most recent soil samples indicated a VOC concentration reduction to below the Regional Water Board’s soil to groundwater leaching ESLs (upon which the Site Cleanup Levels listed in the Site Cleanup Order were based). As a result, residual VOC concentrations in soil in the hot spot area do not appear to present a significant source for leaching to underlying groundwater. Continued groundwater monitoring being performed. No further remediation is required in this area.

Technology Description

RegenOx is an advanced chemical oxidation technology that destroys contaminants through powerful, yet controlled chemical reactions and not through biological means. This product maximizes in situ performance while using a solid alkaline oxidant that employs a sodium percarbonate complex with a multi-part catalytic formula.

3-D Microemulsion factory emulsified is an engineered electron donor material that offers a novel 3-stage electron donor release

profile, pH neutral chemistry and is delivered on-site as a factory–emulsified product.

HRC Primer is a less viscous version of the standard Hydrogen Release Compound (HRC) product. It is a thinner, water-like compound that is typically injected into an aquifer where it releases lactic acid at a rate faster than standard HRC (several weeks), but at a slower, more controlled rate than dispersing aqueous simple sugar solutions or straight lactic acid (several days).

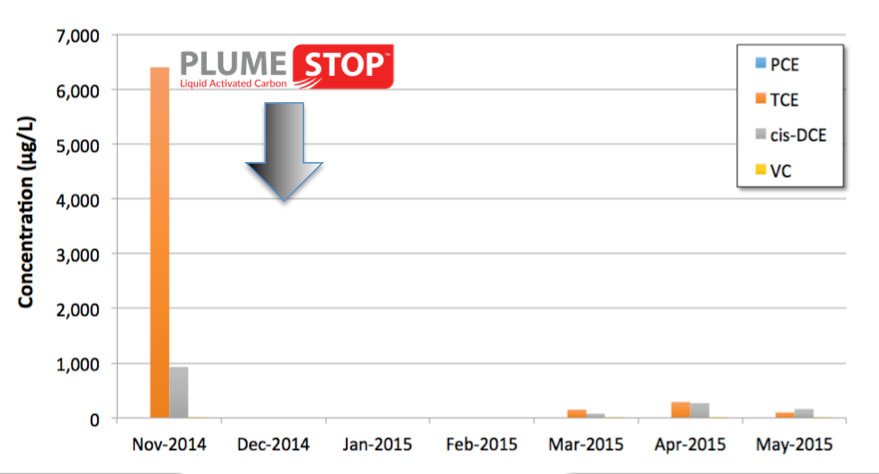

Combined Remedies Approach Reduces CVOCs up to 97% in 78 Days

Project Highlights

- Downtown Chicago site planned for multi-million dollar redevelopment

- Manufacturing operations caused CVOC impacts in groundwater of up to 6500 ug/L

- Redevelopment schedule required effective treatment with timely implementation

- Monitoring wells indicated up to 97% reduction of CVOCs 78 days post treatment

Project Summary

This site in downtown Chicago, was impacted by chlorinated solvents used in various historic manufacturing activities. DCE and TCE concentrations were recorded up to 7,440 µg/L in a sand formation over clay. As the site was to be redevelopment as a hotel and sports arena, and any programme delays would be extremely costly, the client needed a quick and permanent remedy to achieve the stringent target levels (of: total VOC MCL 567 µg/L and TCE MCL 242 µg/L) REGENESIS successfully remediated the groundwater to below target levels within the tight time window.

Treatment

The designed volumes of PlumeStop, HRC, and BDI Plus were successfully applied within the defined treatment zones (see map right) during the application event. A combined volume of 265 m3 of PlumeStop, HRC and BDI Plus was injected via 138 direct push injection points.

Results

78 days post-application, the two key validation wells (AW 3-3 and AW 3-2) observed 80% and 97% reduction in total CVOCs. BDI Plus was used to facilitate the bioaugmentation. As a result, the DHC sp. count and functional genes of the anaerobic metabolic pathways increased significantly from baseline measurements, as determined by QuantArray® analysis. This means that not only contaminant sorption is occurring, but that biodegradation is happening as well. The second and third monitoring round (at 108 and 138 days) confirm the production of breakdown products, indicating that enhanced reductive dechlorination (ERD) is ongoing. Regulatory sign-off is applied for.

What’s Special?

- Unsupported by PlumeStop, bioremediation would not have been an option for a site with such a tight programme. This project shows that accelerated bioremediation using Plumestop can compete with In Situ Chemical Oxidation on time

- The execution of this application was unique because of the tight project programme

- Rapid reduction in groundwater contamination: 80 – 97% from first sampling interval of the total solvents. The concentration levels in all wells are now compliant.

Technology Description

PlumeStop™ Liquid Activated Carbon™ is composed of very fine particles of activated carbon (1-2μm) suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix binding to the aquifer matrix, rapidly removing contaminants from groundwater, and expediting permanent contaminant biodegradation.

HRC® is a controlled release, electron donor material, that when hydrated is specifically designed to produce a controlled release of lactic acid. The newly available lactic acid is critical for the production of hydrogen to fuel anaerobic biodegradation processes in soil and groundwater.

Bio-Dechlor INOCULUM® Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Hexavalent Chromium Remediation at Former Saw Mill

Summary

REGENESIS were retained to carry out the remediation design and site application works to treat groundwater impacted with hexavalent chromium (Cr VI) on the site of a former saw mill in the United Kingdom, Europe. Metals Remediation Compound® (MRC) and 3-D Microemulsion® (3DMe) were applied into the groundwater to provide rapid reduction and immobilisation of the CrVI present. Groundwater samples collected 2 months after application were analysed for CrVI , returning non-detect results.

Treatment

Due to the ground conditions of weathered limestone, treatment was carried out via pre-installed treatment wells at 5 m spacing in the source area and 6 m in the barrier. MRC and 3DMe were co-applied into these wells to target the source area of contamination and to install a reactive barrier at the down-gradient edge of the site to protect a nearby watercourse. MRC and 3DMe provide a powerful combination of wide distribution and strong reducing and immobilising properties.

What’s Special?

- REGENESIS’ injection team completed the site works ahead of schedule to allow the groundwork contractor to prepare the site for housing development.

- The use of MRC and 3DMe allowed for wide spacing of the injection wells and therefore lower drilling costs.

- The treatment approach achieved rapid reductions from up to 15,000 μg/L of Cr(VI) to non-detect within two months, expediting regulatory sign-off and unlocking the site for redevelopment

Technology Descriptions

Metals Remediation Compound (MRC) removes metals such as dissolved Cr(VI) from groundwater via in situ immobilisation (precipitation and/or sorption to soil particles).

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product..

Safe and Simple Excavation Application Provides Long-Term Treatment

Summary

During the demolition and redevelopment of a former petrol filling station, an underground storage tank was removed. The tank had been used for the storage of diesel and had leaked into the surrounding soils and groundwater. The impacted soils were excavated and removed to a waste management facility. The groundwater within the excavation was impacted with dissolved phase hydrocarbons and required further treatment.

Regenesis provided the remediation contractor with a remedial design for the application of ORC Advanced Pellets to treat the residual contamination within the groundwater in and around the open excavation.

Treatment

ORC Advanced Pellets were applied into the groundwater, in the base of the excavation. This was completed by placing them in an excavator bucket and spreading evenly across the area. By using the pelletised version of ORC Advanced, there was no need for mixing or application using pumps and the potential for dust creation was minimised.

The pellets take only minutes to apply and yet provide a controlled release of oxygen into the groundwater for a period of 9-12 months from a single application. The ORC Advanced stimulates the growth of an aerobic biomass which accelerates the biological degradation of dissolved phase hydrocarbon contamination.

What’s Special?

- The use of ORC Advanced Pellets meant that the contractor could backfill the excavation and continue the build programme with minimal disruption.

- The remediation then continued in situ with no need for physical plant taking up valuable space or requiring maintenance.

- ORC Advanced Pellets provide an effective long-term treatment of residual dissolved phase contamination though a very easy, safe and rapid application process.

Product Description

ORC Advanced Pellets (ORC-A Pellets) are a pelletised version of REGENESIS’ widely-used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletised, dry application material minimises airborne dust while eliminating the need for specialised equipment and spray water required for powder-slurry applications. ORC Advanced Pellets are approximately 3-10 mm in size.

Enhanced Reductive Dechlorination with Bioaugmentation Treats Source Area, Stops Plume Migration

Combined Remedy Source Treatment Applied at Florida Dry Cleaner

Project Highlights

- Aggressive source treatment to deplete the high-concentration PCE mass

- Plume treatment with a permeable reactive barrier to cut off the plume

- Low-impact direct-push injections in both areas

Project Summary

A former dry cleaner in an urban setting in central Florida was contaminated with a PCE plume that extended nearly 1,000 feet downgradient from the source. An extensive treatability test involving multiple emulsified vegetable oils and other electron donor technologies indicated that 3-D Microemulsion® would perform best at the site. An enhanced anaerobic bioremediation treatment was implemented in two areas – the source area near the dry cleaner and an area approximately 500 feet downgradient. A total of 13,900 gallons of 3-D Microemulsion was injected into 30 direct push points in the two areas. In addition, 97 liters of Bio-Dechlor INOCULUM Plus (BDI® Plus) bioaugmentation culture was injected to accelerate treatment results.

Remediation Approach

The injections were performed near the former dry cleaner to deplete the source mass and expedite a transition into natural attenuation monitoring. A plume treatment was implemented as a permeable reactive barrier approximately 500 feet downgradient to help mitigate the risk of additional downgradient migration. Injections were completed using direct-push technology.

Technology Description

3-D Microemulsion is an engineered electron donor technology that offers a novel 3-stage electron donor release profile pH-neutral chemistry, and unique subsurface distribution properties.

Bio-Dechlor INOCULUM Plus is a natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español