PetroFix in situ PRB replaces cut-off wall design to benefit redevelopment project

Case study highlights:

- 40m long in situ barrier installation completed within 5 days

- Small working footprint – no disruption to construction works

- This alternative solution provides immediate and long-term groundwater treatment

- GE Awards 2020 winner: The judges commented on the innovative method and recognised the reduced programme and significantly reduced quantities of soil sent to landfill, minimising environmental impact

At the site of a former storage and distribution depot in Coventry, the soils and groundwater were impacted with petroleum hydrocarbons from previous site usage, which included a petrol filling station that had been located just north of the site and also across part of the site itself. Cundall created a multi-phased remediation strategy with Alto Construct to deal with the soils and asked REGENESIS to carry out the groundwater remediation. REGENESIS installed a PetroFix activated carbon permeable reactive barrier at the edge of the site to capture and promote the biological degradation of high levels of dissolved phase contamination migrating on-site, to protect the redevelopment site as well as the adjacent river.

A Fuel Spill Caused by a Truck Rollover in Montana Receives No Further Action Following PetroFix Application

Case study highlights:

- No further action received

- Potential impacts to scenic river eliminated

- 2400 pounds of PetroFix applied to fuel spill excavation

This case study reviews a semi-truck that was hauling gasoline and diesel and overturned into a dry irrigation ditch in Montana. The diesel tanks ruptured and released fuel into the ditch, impacting the shallow water table with petroleum hydrocarbons (PHCs), including benzene, toluene, ethylbenzene, and xylenes (BTEX). The irrigation ditch feeds a larger irrigation canal that empties into the Yellowstone River. In response, an area of approximately 2,500 square feet area was excavated and approximately 800 tons of the grossly impacted soils were removed. Following the emergency response effort, Pioneer Technical Services, Inc. (Pioneer) reviewed the emergency response report, completed a site inspection and met with the property owner to discuss the emergency response clean-up reconstruction methods and materials to be used.

Combined ISCR and in situ sorption of a PCE plume on school grounds in Northern Italy

Case study highlights:

- Safe and easy co-injection of PlumeStop and S-MicroZVI

- 50m long in situ barrier was applied with minimal interference with the school activities

- Significant and rapid decrease of PCE concentrations in all 3 monitoring wells immediately downgradient

An ongoing manufacturing facility located within a major Italian city created a widespread tetrachloroethene (PCE) contaminant plume in the underlying aquifer. The highly aerobic aquifer has inhibited natural attenuation, with no daughter products detected even after many years. Environmental company TAUW is in charge of this site and has implemented hydraulic containment within the factory grounds, as required by law. However, there remained a need to target the plume beyond the site boundary, for which they outlined an in situ solution in collaboration with Prof. Marco Petrangeli Papini from Università La Sapienza di Roma.

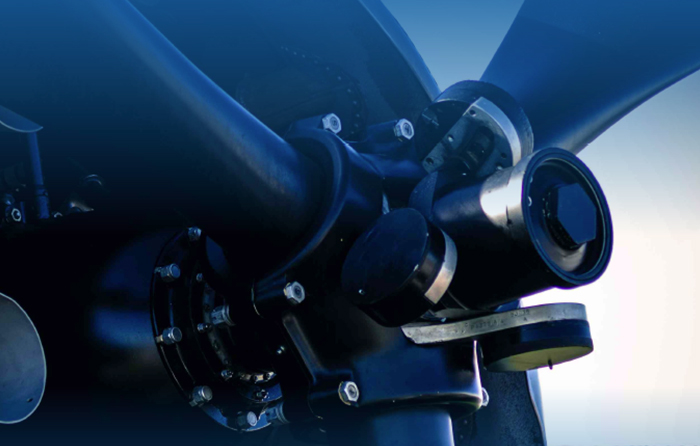

Over 8 Million Cubic Feet of Groundwater Treated In 13 Days

Case study highlights:

- 8 million cubic feet of CVOC impacted groundwater treated

- 88,000 gallons of ERD remedial amendments applied in less than 13 days using novel, innovative tooling and application approach

- The project was completed more than 40% faster than originally scheduled.

This case study reviews the site of a large-scale enhanced reductive dechlorination (ERD) treatment of chlorinated volatile organic compounds (CVOCs) applied in a fractured bedrock aquifer at a voluntary remediation site in Pennsylvania. REGENESIS Remediation Services (RRS) began the application in May 2020 and completed it in less than 13 days, averaging nearly 7,000 gallons of fluid volume injected per day at this active facility. In total, more than 260,000 combined pounds of 3-D Microemulsion, Chemical Reducing Solution (CRS) and Bio-Dechlor INOCULUM Plus (BDI Plus) were injected for ERD treatment of the CVOCs. The extensive injection well network and large injection volume required RRS to develop an innovative injection process and containment design. Two 21,000-gallon frac tanks were delivered to the site to hold deoxygenated water used for mixing and to chase product injections. Mixing for the main high-flow system was performed in two large polyethylene tanks that were constantly recirculated to ensure a homogenous mixture.

PlumeStop Treatment of Chlorinated Solvents in a Bedrock

Successful pilot study uses colloidal activated carbon to protect

nearby surface waters, United Kingdom

Introduction

REGENESIS was asked to provide a remediation solution for a Trichloroethylene (TCE) plume in the UK. We worked closely with Golder to design and implement a novel solution that combined Plumestop, HRC and BDI+ to sorb and biologically degrade the contamination, rapidly and effectively reducing contamination downstream to nondetectable

levels.

Case Study Highlights

This pilot study shows that treatment of chlorinated solvent plumes is possible using PlumeStop even with challenging conditions such as a: co-mingled plume, fractured bedrock setting, and a highly variable hydraulic conductivity.

The PlumeStop in situ permeable reactive barrier rapidly reduced downgradient contaminant concentrations and maintained these through a combination of sorption and biological degradation,protecting the adjacent surface water receptor.

PetroFix Pilot Study Leads To Successful Full-Scale Application

Case study highlights:

- Previous pilot testing results provided promising results leading to a full-scale application

- PetroFix is designed to remediate petroleum contamination completely at the lowest total cost to closure

- Site closure strategy included reducing groundwater concentrations, inhibiting plume migration, and demonstrating plume stability site-wide

This case study reviews a full-scale PetroFix remediation program that was designed and implemented at seven locations to treat petroleum hydrocarbons (PHCs) following a successful field pilot test.

Two post-injection groundwater sampling events were completed in June and September 2019. In December 2019, a supplemental PetroFix injection was completed in the PHC source area onsite following the PersulfOx and ORC-A pretreatment step and groundwater equilibration. Additionally, a new treatment area was added where a small quantity of PetroFix was injected.

Combined Remedy Treats Chlorinated Solvents to Achieve Closure with Florida DEP

Case study highlights:

- Former dry cleaning operations lead to CVOC contaminated groundwater

- AECOM, a global environmental consulting firm, was engaged to develop a solution for this site

- PlumeStop and HRC provide rapid and effective remediation

This case study reviews the site of a chlorinated solvent spill as part of former dry cleaner operations at a retail shopping center in St. Petersburg, Florida. AECOM®, a global environmental consulting firm, was engaged to develop a solution for the site. The application called for an in situ groundwater treatment of low-concentration chlorinated volatile organic compounds (CVOCs). AECOM enlisted REGENESIS® to design and implement an innovative sorption-enhanced reductive dechlorination (ERD) bioremediation approach for treating the CVOC contaminants. The CVOCs included the typical dry cleaner contaminant suite: tetrachloroethene (PCE), trichloroethene (TCE), cis-1,2-dichloroethene (cis-DCE), and vinyl chloride (VC). In October 2017, REGENESIS Remediation Services injected PlumeStop® Liquid Activated Carbon™ and Hydrogen Release Compound®, completing the sorption-ERD remedial application in a single day. The results of the effort led to the Florida Department of Environmental Protection, Southwest District issuing a Site Rehabilitation Completion Order, releasing the property owner from further obligation to conduct remediation at the project site (i.e., site regulatory closure).

Multiple Lines of Evidence Show CVOCs Degrading on PlumeStop, Leading Site to NFA Status

Case study highlights:

- Combined remedy approach proves successful in treating chlorinated solvents at former dry cleaner

- This site provided ideal challenge conditions to demonstrate complete biodegradation using a sorption-ERD approach

- The site was granted NFA status in June 2019 as a result of this pilot study

This case study reviews one of the original PlumeStop® pilot tests for in situ groundwater treatment of chlorinated volatile organic compounds (CVOCs or chlorinated solvents) at a former dry cleaner location in Marina, California. REGENESIS treated the CVOCs using a novel, sorption-enhanced reductive dechlorination (ERD) approach. This approach consisted of immediate sorption followed by the sequential elimination of chlorine from the CVOC molecules, transforming them into non-toxic end products such as ethene, carbon dioxide, and chloride. The CVOC, biogeochemical, and microbial data collected during the pilot test monitoring program provide multiple lines of evidence for post-sorption degradation of the target solvents on the PlumeStop carbon surface. Therefore, the pilot test results confirm the answer to the question: “Do Contaminants Biodegrade When Treated With PlumeStop?”. Biodegradation of CVOCs does occur once sorbed onto a PlumeStop-treated aquifer matrix. These findings led to the site being granted NFA status by the CCRWQCB.

TerraShield Protects Future Occupants from Harmful Vapor Intrusion

Case study highlights:

- TerraShield was considered the safest and most effective choice to protect against the high levels of vapor contaminants found onsite

- The installation of TerraShield eliminated potential health risks for future onsite employees posed by the hazardous vapor intrusion exposure from the TCE and PAH contaminants

- TerraVent, a low-profile trenchless vapor collection system, was installed on this site

A large automotive and supply company planned to build its new corporate headquarters on a 4.5-acre brownfield site recently acquired in Southfield, MI. Soil and groundwater sampling on the property revealed the presence of trichloroethylene (TCE) and polynuclear aromatic hydrocarbons (PAHs). TCE was also identified in soil gas beneath the site. Within the footprint of the planned building itself, contaminant concentrations were found to be in excess of applicable indoor air quality screening levels. The developer utilized brownfield funding from the local authority to conduct the necessary environmental remediation measures.

Remediation of chlorinated solvents under a commercial development, Belgium

Case study highlights:

- How a single application of 3DME resulted in the full reductive dechlorination of a large plume of chlorinated solvents

- How this simple and inexpensive treatment allowed the redevelopment of a highly impacted brownfield site, while allowing construction and economic use to go ahead unimpeded by the remediation occurred beneath the ground

In Belgium, the former Ubell metal-working factory, which had stood abandoned since the 1990’s, was chosen by Spaque to be redevelopment for commercial use. Significant amounts of chlorinated solvents had been observed in the groundwater, both widespread and with high concentrations in the source area. Reductive dichlorination was seen to be occurring naturally, but was stalling at cis-1,2 DCE due to a carbon-limited system. REGENESIS designed a remediation approach that would use a slow-release electron donor to enhance and maintain full and effective reductive dechlorination (Enhanced Reductive Dechlorination (ERD)) of the target contamination.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español