ORC Advanced® Treats Multiple Plumes and High TPH Concentrations

CASE SUMMARY

Past operations at a former U.S. Navy Base in American Samoa had resulted in total petroleum hydrocarbon (TPH) contamination within the subsurface. Currently occupied by an elementary school, the former military base once stored barrels of petroleum-based fuels for military operations. A hydrocarbon sheen was evident following rain events prompting the need for a remedial investigation to determine the extent of contamination within the subsurface. Soil boring samples revealed elevated levels of TPH-diesel, TPH-gasoline, and TPH-motor oil at concentrations exceeding the cleanup standard. Site investigations did not identify any TPH impact to groundwater.

Access to the site and equipment was very limited thus on-site sampling and remediation was conducted only annually when the school was out of session. As a result, a remedial approach was required in which no operations & maintenance would be necessary. In addition, a technology was needed which would not damage on-site structures, successfully treat low permeable soils, and not disrupt the day to day operations of the elementary school. Enhanced bioremediation using ORC Advanced® was chosen since it did not require on-site maintenance and would effectively treat TPH concentrations within a reasonable timeframe.

REMEDIATION APPROACH

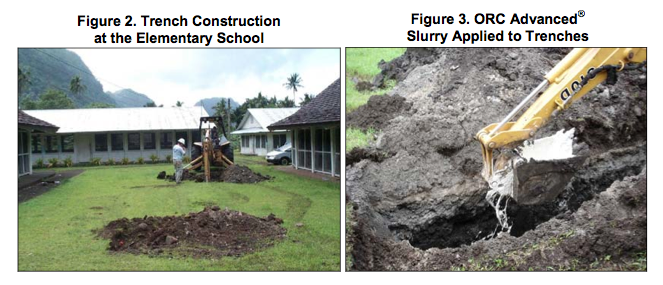

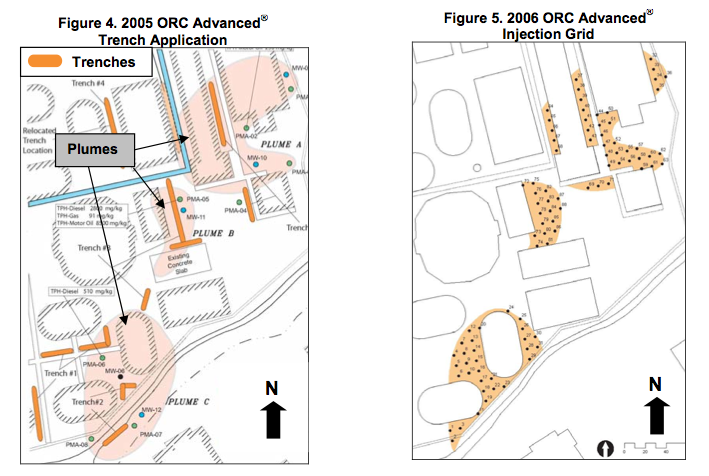

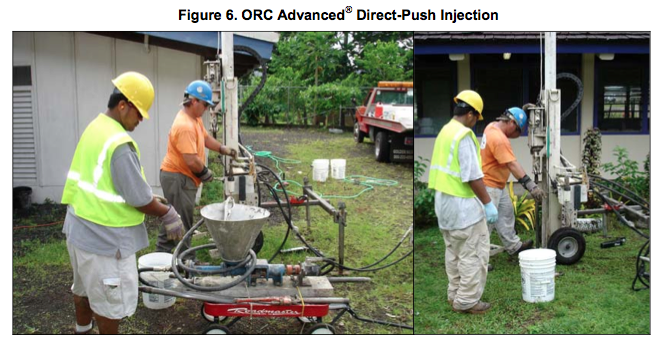

The initial application of ORC Advanced® was applied in 2005 via multiple trenches to address the three identified plumes (Figure 4). ORC Advanced® was mixed with water to form a slurry then placed at the bottom of each trench prior to backfilling (Figure 3). Soil sampling one year later indicated a reduction in TPH levels; however three boring samples remained above the cleanup goal. This was explained by the lack of water available in the subsurface to move the ORC Advanced® radially from the applied trench area. A second application in 2006 was delivered via direct-push injection using approximately 2,000 pounds of ORC Advanced® into a total of 82 injection points (Figure 5 & 6). In 2007, an ORC Advanced® injection application was completed to treat the few remaining hot spots. One last application is scheduled for summer 2008.

RESULTS

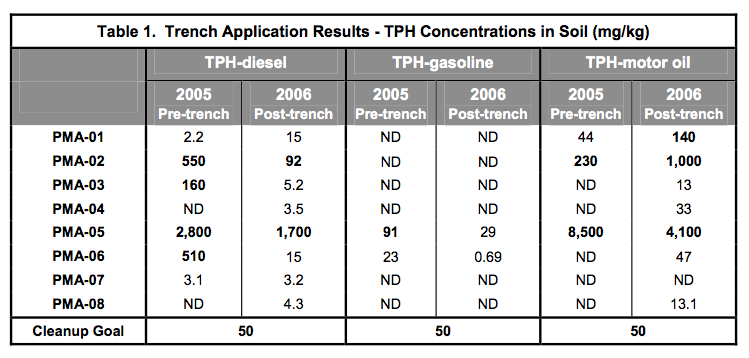

Trench Application

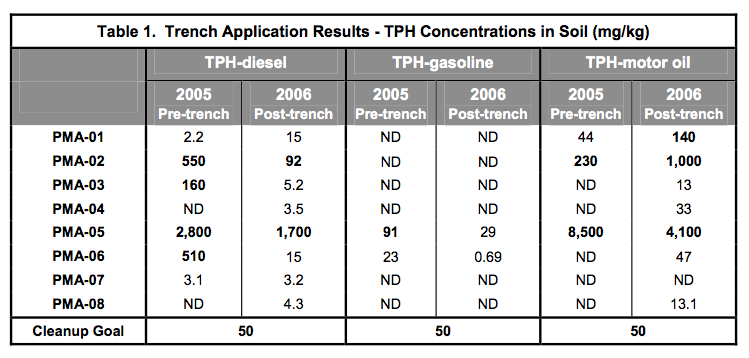

The 2005 trench application was successful in reducing TPH concentrations significantly (Table 1). Within the area of highest concentrations (PMA-05), TPH-diesel was reduced from 2,800 milligrams per kilogram (mg/kg) to 1,700 mg/kg, TPH-motor oil declined by 50% and TPH-gasoline was reduced to below the cleanup goal of 50 mg/kg. Of the eight sampled areas, three remained above the Project Action Level – PMA-01, PMA-02, and PMA-05. Although the trench application was successful in reducing concentrations within the immediate application area, the radius of influence was not great enough to remediate the entire plume. Therefore, a follow up application was designed using direct-push technology.

Direct-Push Application

The direct-push application substantially reduced high concentrations of TPH-diesel and TPH-motor oil (Table 2). Most significant was area PMA-05 where TPH-diesel declined from 1,700 mg/kg to below the cleanup goal and TPH-motor oil was reduced from 4,100 to 120 mg/kg, a 97% reduction. An increase in concentrations was observed as a result of the direct-push technique which mobilized residual contamination from the soil. A direct-push injection was completed in July 2007 to address the remaining concentrations of TPH-diesel and TPH-motor oil. A total of 2,500 pounds of ORC Advanced® were applied using the same design layout as the 2006 application (Figure 5). One last application is planned for summer 2008.

CONCLUSION

To date, one ORC Advanced® trench application and two direct-push injections have been completed. The trench technique was effective within the immediate vicinity of the application. However, in order to achieve a better radius of influence, the direct-push technique was more effective. Additionally, the impact and inconvenience to the site from direct-push was significantly less in comparison to the large trenched areas as shown in Figures 2 and 3.

TPH-motor oil has remained above the cleanup goal as seen in Table 2. This can be explained by the fact that the molecular size of motor oil is more significant compared to diesel and gasoline and, therefore, more time is needed to breakdown the molecule. In addition, as a result of the injection, mobilization of residual contamination from the soil caused an increase in concentrations. The July 2007 application is expected to continue the breakdown of any remaining contamination, including motor oil, towards the cleanup goal. Sampling will again be completed in the summer of 2008 along with one final ORC Advanced® application.

Site Closure via In Situ Aerobic Bioremediation of Petroleum Hydrocarbons

Summary

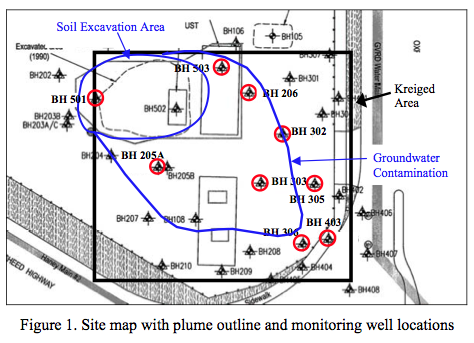

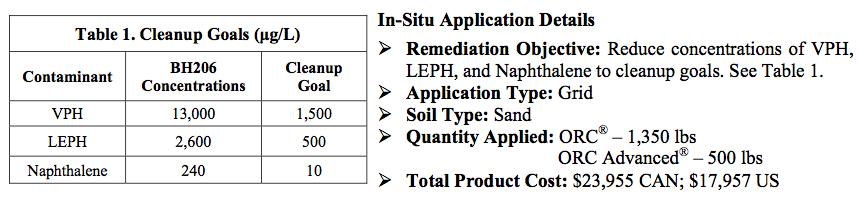

A former fueling facility in Port Coquitlam, BC contained four USTs and accompanying dispensers. The USTs were removed in 1990 after volatile petroleum hydrocarbon (VPH) concentrations were found above regulatory limits. Well BH206 had significant VPH and naphthalene concentrations reaching 13,000 μg/L and 240 μg/L, respectively. In addition, wells BH 303 and BH 205A had concentrations of VPH as high as 5,600 μg/L.

Remediation Approach

Excavation activities removed approximately 1,300 m3 of contaminated soil which were later disposed of at a permitted facility. Following the excavation, a groundwater remediation program was implemented using 1,350 lbs of Oxygen Release Compound (ORC®). An ORC slurry was added to the backfill and injected into the groundwater plume to further reduce VPH concentrations as well as light extractable petroleum hydrocarbons (LEPH). A second application using 500 lbs of ORC Advanced® was applied one year after the ORC application to continue reducing trends of petroleum hydrocarbons.

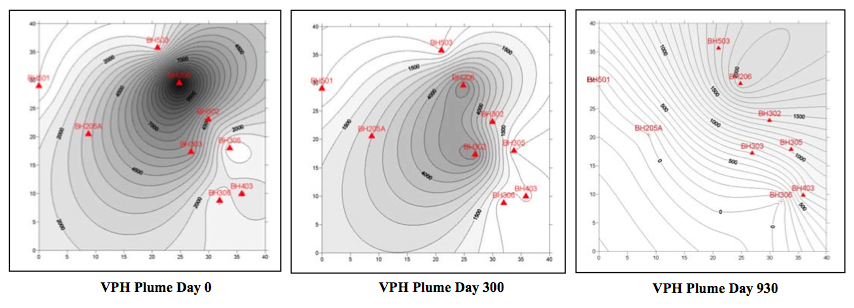

VPH Time Lapse Shots

Results

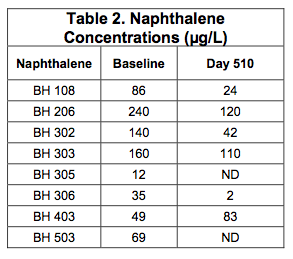

As shown in the VPH time lapse shots on the front, VPH reduction occurred across the plume. Approximately, one year after injection VPH declined from 13,000 μg/L to 4,300 μg/L in well BH206 and well BH303 showed a decrease of 80%. Downgradient of the source area VPH was reduced below cleanup goals. Prior to injection, a total of 7 wells had LEPH concentrations above the standard (500 μg/L). By day 510, four wells reached concentrations below cleanup goals. Reduction of naphthalene was also seen across the contaminated area (Table 2). Most notable are the 3 wells that reached the cleanup standard 510 days after injection.

Within 3 years of the initial application, all contaminants of concern were reduced to below the cleanup goals. Concentrations of VPH and LEPH were reduced by 1 to 2 orders of magnitude and naphthalene declined from a high of 280 μg/L to 7.9 μg/L. The site achieved closure approximately 5 years after commencing remedial treatment.

Combined RegenOxTM and ORC Advanced® Application Treats TPH and BTEX

Introduction

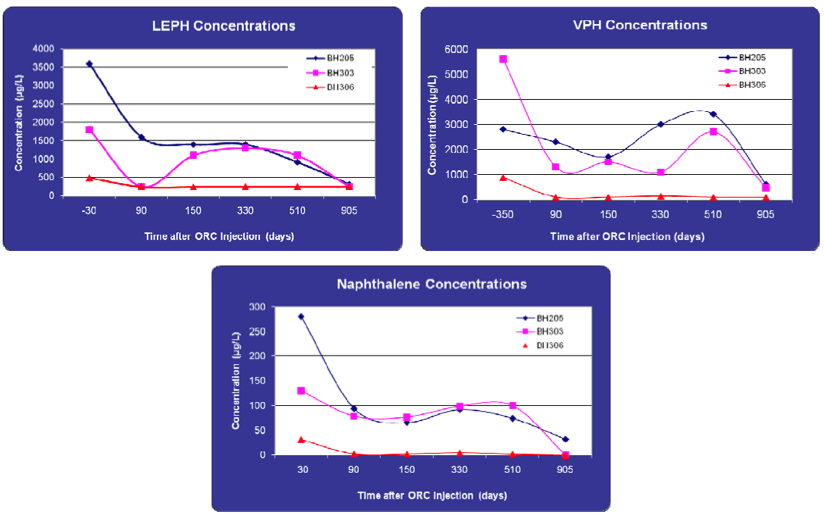

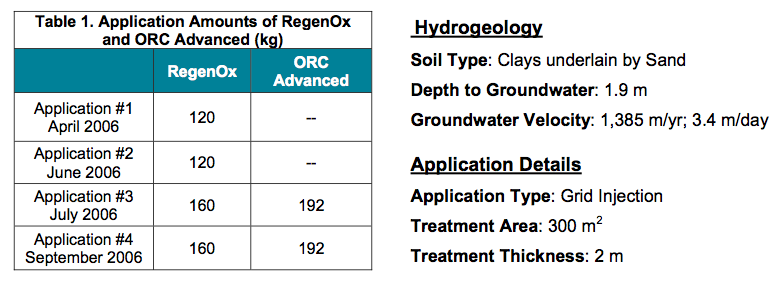

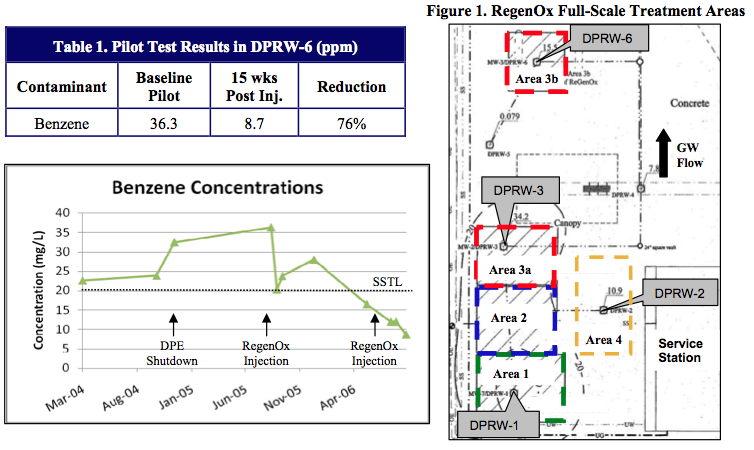

Operations at a former car dealership resulted in petroleum hydrocarbon contaminated soil and groundwater. In the source well SB7, groundwater concentrations of total petroleum hydrocarbons (TPH) had increased to 250 parts per million (ppm) and concentrations of benzene, toluene, ethylbenzene, and xylenes (BTEX) were present at more than 400 ppm. In order to reach the TPH site specific target level (SSTL) of 19.2 ppm, a combined remedial approach using chemical oxidation and enhanced aerobic bioremediation was implemented. Injections of RegenOxTM and ORC Advanced® were applied in four separate injection events (Table 1). The combined approach was designed to treat the high concentrations and promote aerobic bioremediation of any remaining residual contamination.

Remediation Approach

The remedial objective was to reduce high concentrations of TPH to below the SSTL of 19.2 ppm. RegenOx was applied in April 2006 and June 2006 across the plume (Figure 1). Both RegenOx and ORC Advanced were applied separately in July 2006 and September 2006. (Table 1)

In Situ Treatment Results

Shortly after the initial RegenOx chemical oxidation treatment, TPH was reduced by an average of 67% (Graph 1). As is typical following the first chemical oxidation application, contaminant rebound occurred after approximately one month. This is primarily a result of rapid desorption of sorbed phase contaminants from soil into groundwater and the 30 day longevity of RegenOx. Three follow up RegenOx injections were applied to continue treatment and eliminate the remaining contamination. Additionally, two ORC Advanced injections were performed to provide a long-term (12 months on average) oxygen source for enhanced aerobic bioremediation.

Shortly after the initial RegenOx chemical oxidation treatment, TPH was reduced by an average of 67% (Graph 1). As is typical following the first chemical oxidation application, contaminant rebound occurred after approximately one month. This is primarily a result of rapid desorption of sorbed phase contaminants from soil into groundwater and the 30 day longevity of RegenOx. Three follow up RegenOx injections were applied to continue treatment and eliminate the remaining contamination. Additionally, two ORC Advanced injections were performed to provide a long-term (12 months on average) oxygen source for enhanced aerobic bioremediation.

RegenOx was effective at reducing TPH to below the SSTL in all wells, excluding SB7 (Graph 1) which was located within the source area. However, a reduction of 95% occurred in SB7 within two weeks of the initial RegenOx injection. Rebound was observed in this area throughout the treatment, indicating that sorbed phase TPH was more prevalent around this well. RegenOx reduced the overall TPH loading of the soils and maintained TPH concentrations in groundwater to below 60 ppm. The ORC Advanced applications are expected to further TPH reduction in this area via enhanced aerobic biostimulation beyond the length of the monitoring program.

Conclusion

As a result of the RegenOx applications, concentrations were reduced quickly and cost-effectively within weeks of the injections. It is expected that the remaining concentrations above the SSTL in Graph 1 will be reduced as ORC Advanced continues to release oxygen. Successful closure was achieved due to the overall reduction in TPH concentrations, the observed reduction in contaminant concentrations in the source area, and the expected future reductions from the application of ORC Advanced.

RegenOx® Treats Benzene in Low Permeability Soils

Introduction

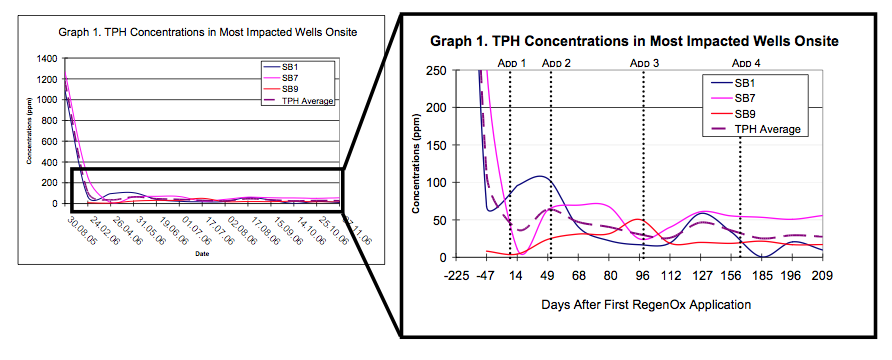

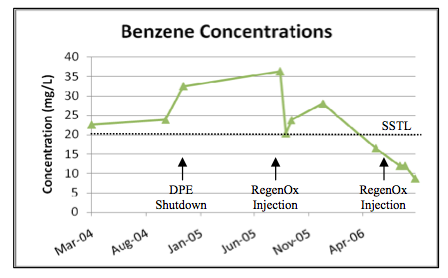

Service station operations created a benzene contaminant plume in tight subsurface soils. A dual-phase extraction system (DPE) was installed and removed a total of 9,965 pounds of petroleum hydrocarbons over two 90-day operational periods. However, contaminant removal reached asymptotic levels and a more effective remedial strategy was needed to address the remaining benzene concentrations. The DPE system was shut down in December 2004 and RegenOx® was selected to evaluate the effectiveness of reducing benzene and MTBE concentrations in tight soil lithology.

Description of Activities

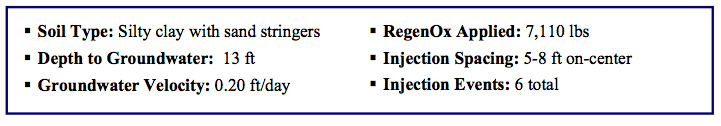

RegenOx was pilot tested around well DPRW-6 to evaluate its effectiveness in tight soil. A total of 1,439 pounds of RegenOx was applied near well DPRW-6 as a pilot test in August 2005 (510 lbs) and July 2006 (929 lbs). Benzene concentrations declined within 15 weeks by 76% and successfully reached the Site Specific Target Level (SSTL) (Graph 1), prompting a design for full scale implementation.

The objective of full-scale treatment was to provide rapid mass reduction of benzene concentrations and reach the SSTL of 20.1ppm across the 9,100 ft2 source area. Benzene rebound at DPRW-6 (the original pilot test well) six months post-injection suggested that a previously unidentified plume had re- contaminated that area. After additional site characterization was completed, 7,110 pounds of RegenOx were applied during six injection events over five treatment areas (Figure 1).

The RegenOx injections were performed over a 6 month period due to weather delays. Monitoring was conducted to observe potential contaminant rebound from areas requiring additional injections. The applications targeted a treatment thickness of 14-20 feet bgs into silty clay with intermittent sand “stringers”. RegenOx was injected using a top-down direct-push injection technique with 5-15 lbs of RegenOx injected per vertical foot.

Results

Prior to the full-scale application, benzene concentrations exceeded the SSTL of 20.1ppm in all wells. Monitoring over a 7 month period prior to remedial treatment indicated an increase in concentrations from 12 – 32ppm to 20.4 – 44.1ppm.

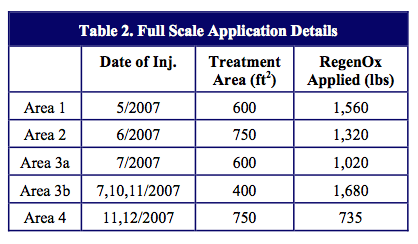

RegenOx was applied over six injection events as indicated in Table 2. Sampling conducted

after the final application event in December 2007 indicated a benzene reduction to at or below the SSTL in all wells (Graphs 2) including the original pilot test well DPRW-6. As monitoring continued, a decline in benzene concentrations persisted via natural attenuation and all wells sampled below 10ppm in August 2009. Based on the reducing trend observed over the past 12 months, the site was recommended for closure.

Rapid Reduction of VOCs Results in Site Closure

Summary

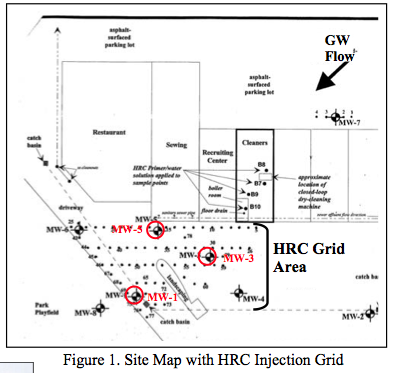

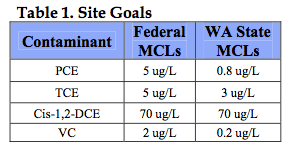

Subsurface investigations at a dry cleaning facility revealed elevated levels of PCE and other regulated daughter products. A remediation technology was needed that could cost-effectively reduce the contaminants to the Washington Department of Ecology’s (WDOE) cleanup levels. HRC was chosen for groundwater remediation due to its ability to provide a low cost solution for site restoration. A groundwater monitoring program was created to assess the efficacy of remediation. The results from this program indicate a significant reduction in all contaminants and provides convincing evidence that the application of HRC to a chlorinated solvent contaminated site results in successful site cleanup.

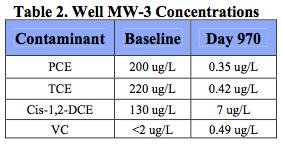

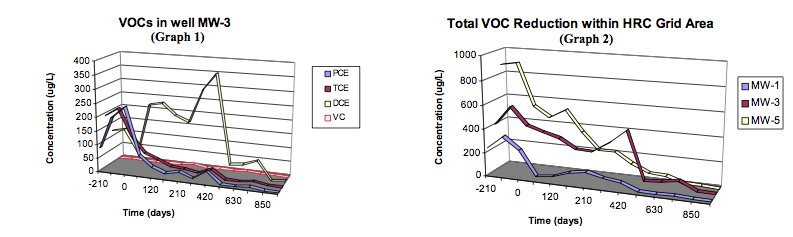

Conclusions

Total VOCs were reduced across the HRC grid area shortly after injection. Wells MW-1, MW-3, and MW-5 (Graph 2) were situated within the HRC grid area and thus represented the behavior of HRC. The results indicate a significant reduction in the concentration of PCE and its related daughter products. PCE and TCE were reduced by 99.8% and DCE was reduced by 94.5%. Similar results were displayed in all other wells affected by HRC. As a result of HRC treatment, PCE, TCE, and DCE levels have been reduced to 10 times below the federal standards. Although VC has dropped to 4 times below federal standards, contamination levels still exceed WDOE MCLs of 0.2 ug/L. This site is expected to gain regulatory closure in the near future once VC is reduced to 0.2 ug/L.

Combined DPE System and HRC Treat TCE and Freon in Tight Soils

SUMMARY

Site investigations completed at a former manufacturing facility indicated significant amounts of volatile organic compounds (VOCs) in the vadose zone and shallow groundwater. The plume originated beneath an on-site structure with concentrations of trichloroethene (TCE) and Freon 113 as high as 3,000 parts per billion (ppb) and 220 ppb, respectively. In order to reduce the impact to groundwater from the vadose zone, a dual-phase extraction (DPE) system was installed for the initial phase of remediation. The DPE system removed a significant amount of TCE and Freon 113 from the source area and eliminated further transport to groundwater. However, the hydraulic gradient changed as a result of the DPE system and pulled in additional cross gradient Freon which increased concentrations. In order to achieve site closure, the DPE system was shutdown and the remaining residual VOCs were treated via enhanced anaerobic biodegradation using Hydrogen Release Compound (HRC®). The HRC application was expected to reduce TCE and Freon 113 concentrations in groundwater to the cleanup goals and act as a reactive barrier to inhibit migration to downgradient areas.

TREATMENT APPROACH

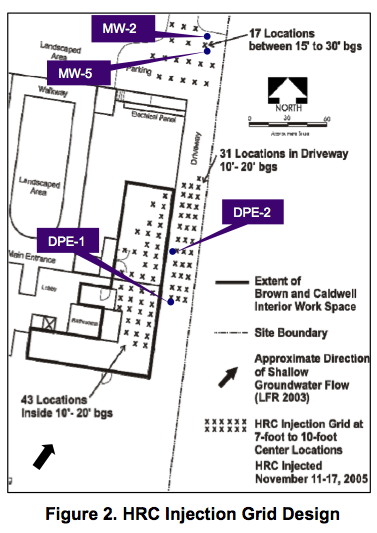

A subslab soil gas investigation was conducted at the site to assess the vapor concentrations of VOCs present in the soil underlying the on-site office building. Although the results of this investigation did not correlate to indoor air concentrations that would be a human health concern, a passive subslab soil gas ventilation system was installed as a further protective measure for site occupants. A total of three subslab vent ports were horizontally constructed beneath the building’s concrete foundation, with each port consisting of 6-feet long, 3-inch diameter perforated pipe wrapped in a filter sock and sealed in place (Figure 1).

To treat the remaining groundwater contamination and bring the site to closure, an in-situ application of HRC was performed. An initial injection using HRC Primer was applied prior to HRC in order to reduce concentrations of competing electron acceptors such as nitrate and sulfate. HRC was then applied beneath the on-site structure and along the east perimeter of the building (Figure 2). An additional barrier application was injected downgradient to prevent off-site migration.

HRC APPLICATION

- Application Type: Grid & Barrier

- Product Applied: HRC®

- Quantity Applied: 600 lbs HRC Primer; 12,240 lbs HRC

- Product Cost: ~$70,000 (HRC Primer + HRC)

- Soil Type: Silt and Silty Sand

- Groundwater Velocity: Low Permeability

- Depth to Groundwater: 7-10 feet

RESULTS

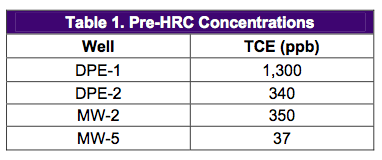

Prior to the HRC injection, TCE concentrations had been increasing over the previous 6 months (Graph 1). A high of 1,300 ppb, observed in DPE-1, indicated a flux of contamination occurring within the subsurface as a result of the DPE system shutdown. Approximately 5 months after the HRC injection, TCE declined to 7.5 ppb, a 99% reduction. Similar reducing trends were observed in monitoring wells DPE-2, MW-2 and MW-5 as concentrations were reduced to below 150 ppb in each well.

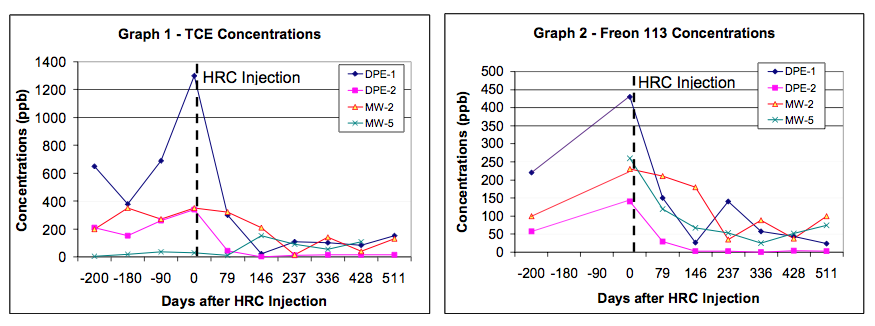

Similarly, an influx of Freon was observed in response to the DPE system shutdown just prior to the HRC injection (Graph 2). Concentrations declined rapidly over the next 6 months following the application as Freon declined from 430 ppb to 27 ppb in DPE-1. Over the next 17 months Freon was reduced by as much as 98% to below 100 ppb in all wells.

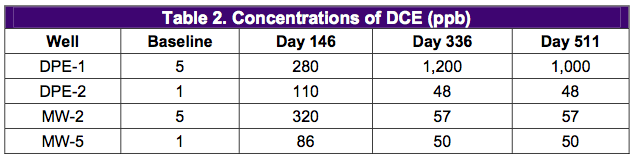

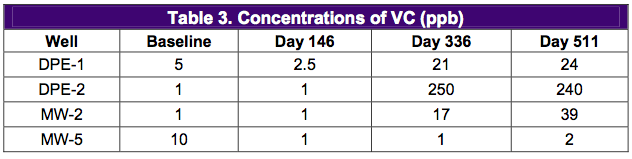

An increasing trend was also observed in total organic carbon (TOC) and metabolic acids corresponding to the decline in TCE and Freon. Concentrations of DCE, which had not been previously sampled above the detection limit, also increased (Table 2). As DCE concentrations began to decline, elevated levels of VC were observed (Table 3). Little to no ethene was detected.

A second application was applied 2 years after the initial HRC application to continue DCE and VC reduction. Approximately 6,200 pounds of HRC was applied using 91 injection points, similar to the original design in Figure 2. As monitoring continues, it is expected that the follow up application will reduce concentrations to the cleanup goals.

3-D Microemulsion® Enhances Reductive Dechlorination and Reduces PCE and TCE Concentrations to Non-Detect

CASE SUMMARY

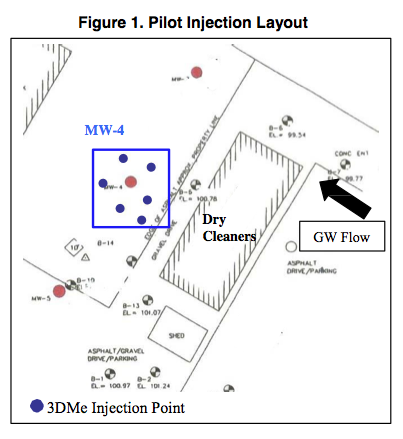

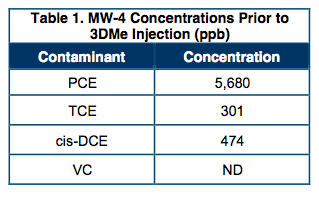

Operations at a dry cleaning facility in Illinois resulted in elevated levels of chlorinated ethenes in the subsurface. Downgradient of the contaminant source (in Well MW-4), the total chlorinated compound concentration was greater than 6,400 parts per billion (ppb), the main contaminant being tetrachloroethene (PCE). A pilot test using Hydrogen Release Compound (HRC®) was initially designed and deployed to produce conditions favorable for the reduction of contaminants. Well MW-4 was the designated sampling point to observe the contaminant reduction. The HRC pilot application was mis-applied over a 20 foot vertical interval instead of the recommended and planned 10 foot interval, resulting in under-dosing of HRC and only moderate treatment performance. A second application was performed 18 months later using the correct dosing of 3-D Microemulsion (3DMe)®.

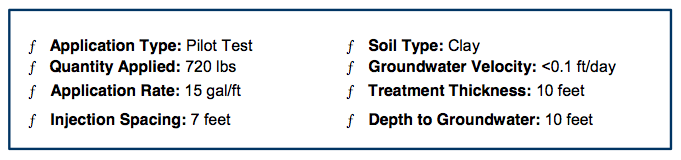

REMEDIATION APPROACH

3-DMicroemulsion is a completely new molecule with staged hydrogen release capabilities and is applied as a microemulsion for enhanced distribution. The 3-D Microemulsion was directly injected at 6 locations surrounding the targeted monitoring well MW-4 (Figure 1). It was injected at a rate of 120 pounds per injection point and at 10 to 20 feet below ground surface (at the correct 10 foot interval). The injection points were spaced approximately 7 feet from one another.

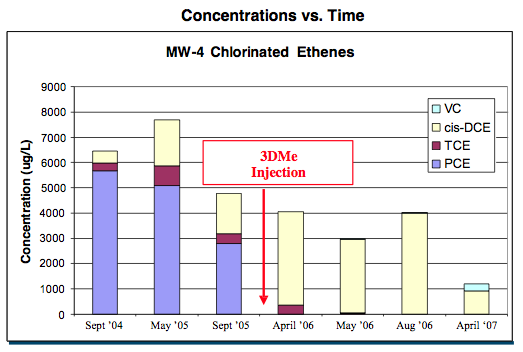

RESULTS

Although HRC was applied and under-dosed in September 2004, moderate increases in the reductive dechlorination process were observed near Well MW-4. The moderate effect resulted in a 50 percent decrease in PCE concentrations. As expected some daughter products were also produced.

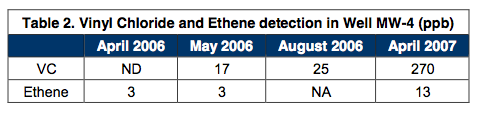

Within 30 days of the 3DMe application, PCE was reduced from 5,680 ppb to non-detect followed by a similar reduction in TCE. A reduction of 77 percent was observed in cis-DCE between August 2006 and April 2007. Slight increases in vinyl chloride (VC) and ethene indicated that complete dechlorination was occurring with no stalling effect (Table 2).

CONCLUSION

Biostimulation using 3-D Microemulsion was successful in treating the target contaminants as a result of the proper dosing/emplacement of the material and overall product performance. In MW-4, PCE and TCE were reduced to non-detect while total chlorinated compounds were reduced by more than 70 percent.

3-D Microemulsion® Bio-Barrier Rapidly Treats Cis-DCE and Vinyl Chloride Contamination and Maintains Reductive Dechlorination Over a 1,200-Day Period

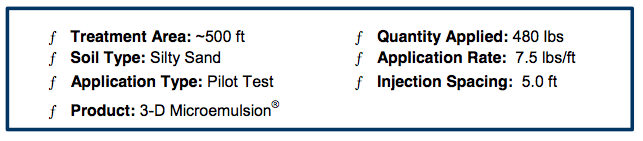

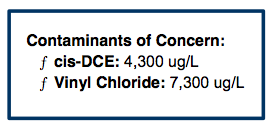

CASE SUMMARY

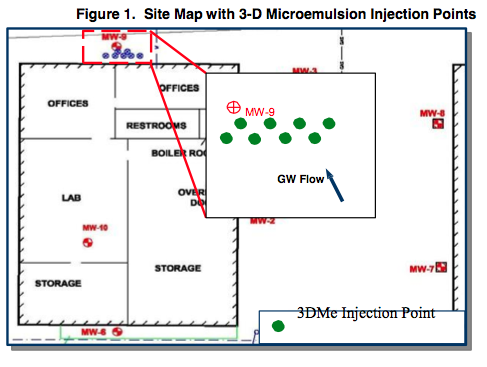

Cis-1,2-dichloroethene (cis-DCE) and vinyl chloride (VC) were migrating off-site at this commercial facility. A pilot test of enhanced anaerobic bioremediation was performed to determine if a bio-barrier using 3-D Microemulsion, a form of HRC Advanced®, could effectively reduce the cis-DCE and VC contamination before it moved off-site. The remediation design included the subsurface injection of 3-D Microemulsion upgradient of contaminated well MW-9.

TECHNOLOGY DESCRIPTION

Reductive dechlorination is a process used to degrade certain contaminants in groundwater (e.g., cis-DCE and VC) to ethene. 3-D Microemulsion is a highly effective agent to facilitate this process. 3-D Microemulsion is composed of free lactic acid, controlled-release lactic acid (polylactate), and certain fatty acid components esterified to a carbon backbone molecule of glycerin. When injected into contaminated soil and groundwater, 3DMe produces a sequential, staged release of its electron donor components. The immediately available free lactic acid is fermented rapidly while the controlled-release lactic acid is metabolized at a more gradual rate. The fatty acids are converted to hydrogen over a mid- to long-range timeline giving 3DMe an exceptionally long electron donor release profile. This staged fermentation provides an immediate, mid-term, and very long-term controlled release supply of hydrogen (electron donor) to fuel the reductive dechlorination process.

REMEDIATION APPROACH

The objective at the site was to demonstrate the ability of 3-D Microemulsion to prevent the off-site migration of cis-DCE and VC by contaminant reduction. The reduction was to be achieved by the introduction of 3DMe into the subsurface through 8 injection points spaced 5 feet apart (Figure 1).

RESULTS

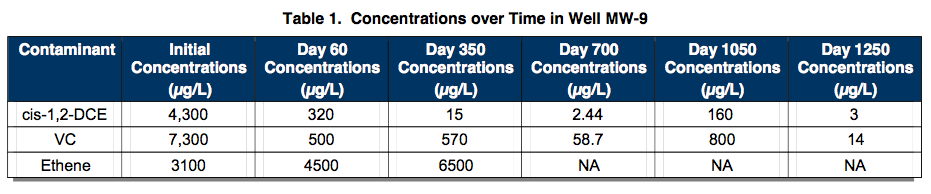

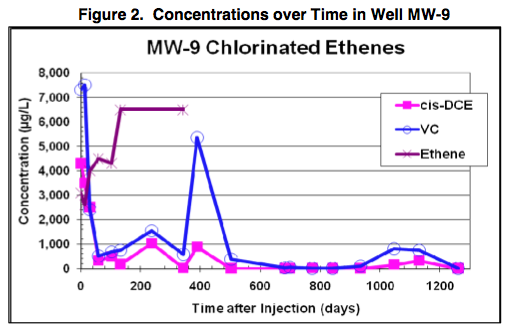

Within 60 days of the application of 3-D Microemulsion, concentrations of the target contaminants were significantly reduced (Table 1 and Figure 2). Over the 1,200-day monitoring period, cis-DCE was reduced by a magnitude of 3 from 4,300 to 3 micrograms per liter (μg/L). VC was reduced by 2 orders of magnitude from 7,300 to 24 μg/L, interrupted briefly by an anomalous spike likely to be laboratory error. As a result of this process, ethene concentrations increased by 102 percent, from 3,100 to 6,500 μg/L, after 130 days (a clear indication of complete dechlorination). Elevated levels of ethene were maintained for more than 300 days until ethene monitoring ended at Day 350 (Figure 2)

CONCLUSION

Overall, the results of this pilot test clearly show that when using 3-D Microemulsion, chlorinated ethene degradation via enhanced reductive dechlorination can be achieved both rapidly (60 days after injection) and successfully maintained over the long term.

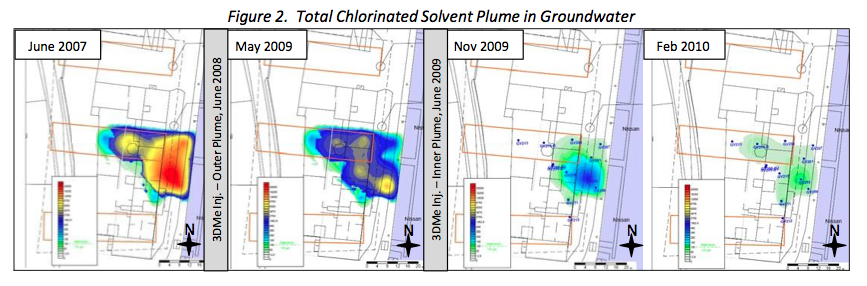

Enhanced Reductive Dechlorination of Chlorinated Solvents in Groundwater Enables Development of Contaminated Site

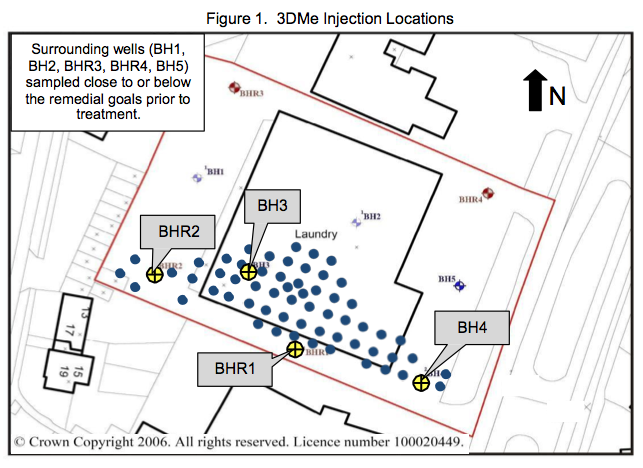

A former dry cleaning site was scheduled for redevelopment into residential properties. Site investigations revealed that past laundry operations had resulted in chlorinated solvent contamination within the groundwater. Concentrations of tetrachloroethene (PCE) were increasing with little to no measureable daughter products being observed, indicating a lack of reductive dechlorination occurring in the subsurface. ENVIRON UK Ltd. completed a Detailed Quantitative Risk Assessment (DQRA) for the contaminants of concern on the site and liaised with the regulatory authorities in order to agree on site specific target levels (SSTL) for the remediation project. Anaerobic biostimulation using an electron donor was chosen to biologically reduce chlorinated solvent concentrations. The majority of contamination was delineated around wells BHR1, BHR2, BH3, and BH4. Within the most impacted well, BH4, the total chlorinated solvent contamination had reached approximately 4,000 micrograms per litre (μg/L).

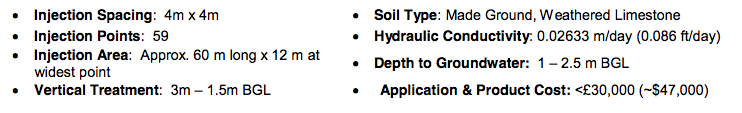

3-D Microemulsion (3DMe®) Application

3-D Microemulsion (3DMe), supplied by Regenesis Ltd., uses a 3-stage donor release profile allowing for the immediate, mid-range and long-term release of hydrogen into the groundwater. The hydrogen is used to increase the mass and activity of indigenous microorganisms performing reductive dechlorination. 3DMe was mixed with water to form a microemulsion for injection. Approximately 1,250 kg (2,750 lbs) of 3DMe was mixed with water at a ratio of 20 parts water to 1 part 3DMe and injected using the grid design shown in Figure 1.

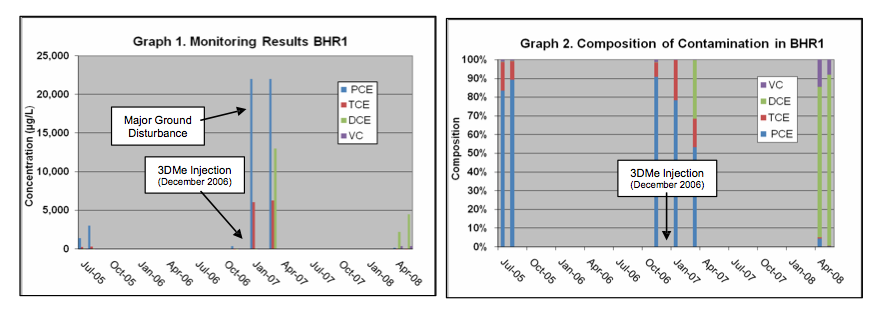

BHR1 – Southern Plume Boundary

PCE in well BHR1 (Graph 1) reached concentrations of up to 3,000 μg/L prior to treatment. Approximately one month after the 3DMe injection and following the removal of a concrete slab and excavation works, an increase in PCE and trichloroethene (TCE) concentrations was observed, peaking at 22,000μg/L and 6,300μg/L, respectively. This was attributed to an influx of chlorinated solvents caused by a physical disturbance and a rain event which mobilised contamination from the capillary fringe zone. Despite these peaks, PCE and TCE concentrations declined significantly to approximately 20 μg/L at 17 months post-injection. Concentrations of DCE increased to a peak of 13,000 μg/L as PCE and TCE were dechlorinated, followed by a decline to below 5,000 μg/L. Vinyl chloride (VC) was also detected at approximately 400 μg/L. The total chlorinated solvent mass was reduced by over 80% in 17 months.

The chlorinated solvent contamination in BHR1 comprised of 90% PCE prior to the application (Graph 2) with little evidence of significant reductive dechlorination occuring. Following the injection of 3DMe, concentrations of PCE and TCE declined to non-detect with the sequential appearance and degradation of daughter products indicating the decline in contaminant concentrations was due to enhanced reductive dechlorination.

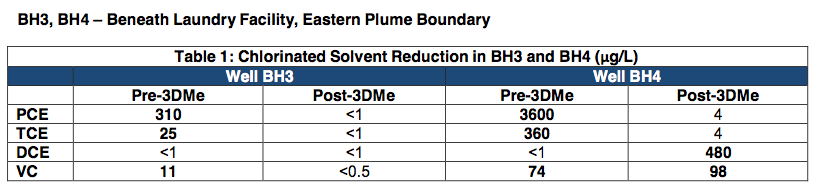

BH3, BH4 – Beneath Laundry Facility, Eastern Plume Boundary

Prior to the 3DMe application, concentrations of parent products PCE and TCE were stable indicating a low rate of dechlorination was occurring. Within three months of the 3DMe injection, concentrations of PCE and TCE were reduced to near non-detect levels while DCE and VC concentrations sequentially increased. At ten months post- injections, all contaminants of concern in well BH3 had reached non-detect levels and continued reduction was observed in well BH4. It is anticipated that the long-term release profile of 3DMe will maintain an anaerobic environment for further reduction in this area.

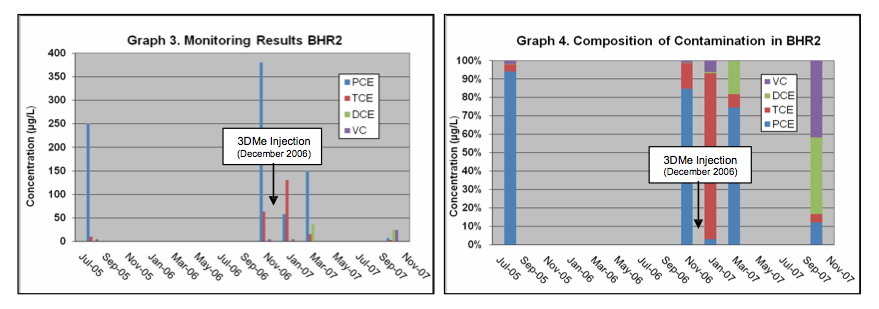

BHR2 – Western Plume Boundary

Well BHR2 (Graph 3) contained almost 400 μg/L total chlorinated solvents prior to the 3DMe injection. Within one month of the application, PCE was reduced to 4 μg/L while TCE concentrations initially rose to approximately 130 μg/L and then declined to approximately 15 μg/L. The reductive dechlorination sequence continued as DCE increased to 35 μg/L then declined. Concentrations of VC remained reduced. An analogous spike in PCE concentration was observed similar to that observed in well BHR1 following the concrete slab removal. It is notable that the spike comprised the parent product PCE whilst daughter product trends were not notably affected. This would be consistent with an influx of fresh contamination following the disturbance, while on-going degradation of the original contamination proceeded. Following this peak, concentrations of total chlorinated solvents declined to below 60 μg/L at 22 months post-injection.

Before the application of 3DMe, the chlorinated solvent contamination in BHR2 comprised of up to 95% PCE (Graph 4). Following the injection of 3DMe, the PCE concentration reduced by 98% and the TCE declined by 95% within 22 months. As seen in well BHR1, the sequential appearance and degradation of daughter products was observed indicating that enhanced reductive dechlorination was occurring.

CONCLUSION

Prior to remediation work commencing, concentrations of PCE in the groundwater were increasing presumably due to ongoing desorption from impacted soils and infiltration of the capillary fringe zone. Minor concentrations of TCE and DCE indicated a lack of reductive dechlorination was occurring and enhanced anaerobic biostimulation was needed in order to reach the SSTLs. Within one month of the 3DMe application, strong evidence of reductive dechlorination was observed as PCE and TCE declined by more than 96% to non-detect levels and breakdown products DCE and VC increased, then declined.

Chlorinated solvent concentrations throughout the plume were reduced towards the cleanup goals within ten months of the 3DMe application, representing a total contaminant mass reduction of more than 80%, despite influx of additional contamination. Further reduction is expected as 3DMe continues to enhance the reductive dechlorination process allowing for continued treatment of the remaining chlorinated solvents. Redevelopment of the site has since been completed with the appropriate regulatory authority sign off in place. The remediation was achieved through a single injection event costing less than £30,000 for 3DMe and application fieldwork combined.

Successful Treatment of Chlorinated Solvents using 3‐D Microemulsion (3DMe®) allows for Housing Redevelopment

BACKGROUND

Groundwater remediation was required at a former industrial site in order to allow for the completion of a large housing development project consisting of 330 apartments along the shore of a river (Figure 1). Membrane Interface Probe (MIP)1 data was used to delineate both the vertical and lateral extent of cis‐1,2‐ dichloroethene (DCE) and vinyl chloride (VC) contamination at the site. To enhance anaerobic bioremediation and bring the site to closure, 3‐D Microemulsion (3DMe®) was used to treat DCE and VC to the cleanup goals. Chlorinated solvent treatment was successful, achieving a 98 – 99% reduction in DCE and VC concentrations within 20 months (Figure 2). The site was granted closure and redevelopment was approved by the regulatory agency.

REMEDIATION HIGHLIGHTS

- Rate of dechlorination increased from 50% to nearly 100% as a result of the 3DMe injection

- Concentrations of DCE and VC reduced to below the cleanup goals

- Significant ethene production from the breakdown of DCE and VC

- Site closure achieved

- The success of the project was both supported and validated by the use of MIP data.

GROUNDWATER REMEDIAL STRATEGY

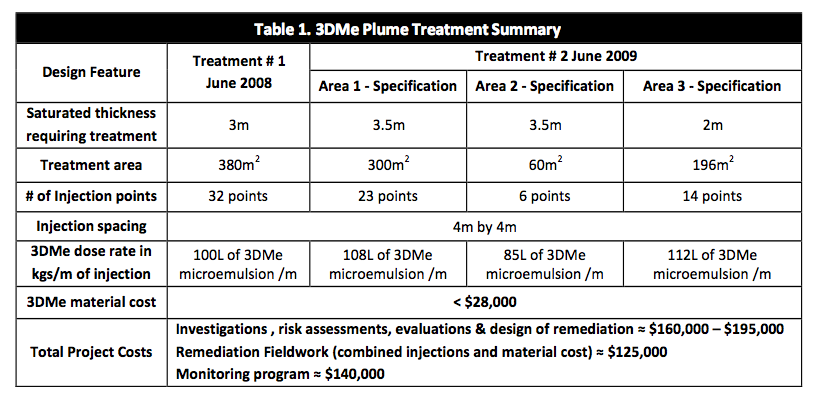

The remedial objective was to reduce concentrations of DCE and VC contamination in the groundwater to below the cleanup goal of 100μg/L. The maximum concentrations of DCE and VC were sampled at 19,000 μg/L and 12,000 μg/L, respectively. The 3DMe application was undertaken in two stages to allow for demolition works on‐site. Phase one (June 2008) included the injection of 3DMe into the eastern and western portions of the plume. Phase two (June 2009) included the injection of 3DMe in the previously inaccessible central plume area. Details of the injection are given in Table 1.

RESULTS

The degree of dechlorination was calculated to determine the progress of reductive dechlorination on‐site. Over the course of the treatment, a significant increase in full reductive dechlorination was observed as concentrations of DCE and VC were broken down to ethene. The degree of dechlorination increased from approximately 50% to nearly 100% within the treatment area.

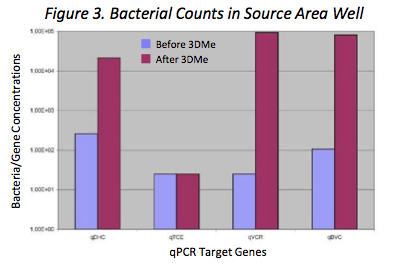

Quantification of microbial populations pre‐ and post‐3DMe application, clearly demonstrated that the microbial populations had increased (Figure 3) and were supported by the controlled supply of hydrogen from 3DMe to the treatment area. This was complimented by a corresponding increase in the degradation rate after the treatment was undertaken.

Compound Specific Isotope Analysis (CSIA) was undertaken as a final line of evidence. Transformation of organic compounds by biological processes can cause significant shifts in the ratios of 13C to 12C (δ13C) in both the reactants and products of the reaction. This occurs as a result of slower degradation kinetics associated with the heavier isotope 13C in comparison to 12C. As a result, molecules with the lighter isotopes tend to be transformed more rapidly, resulting in isotopic fractionation between 13C in the residual reactant and 12C in the initial product. For example, isotopic fractionation was reported for both DCE (‐9.1 to +5.2‰) and VC (‐22.0 to +27‰) between May 2008 and February 2010. This is evidence that the reduction in chlorinated solvent concentrations was not the result of abiotic processes such as physical dilution and dispersion, as isotope fractionation typically only occurs due to biological degradation of the chlorinated solvents.

CONCLUSION

Within two months of the 3DMe application, the rate of reductive dechlorination increased substantially. This was evidenced by:

- Sequential production and degradation of daughter compounds

- Significant increase in ethene concentrations post‐3DMe injection

- An increase in biomass and activity of microorganisms performing reductive dechlorination

- Isotopic fractionation between the parent and daughter compounds resulting from degradation

- An overall reduction in chlorinated compound concentrations in the groundwater

Contaminant levels throughout the plume were reduced to below the cleanup goals within 20 months of the 3DMe application and regulatory acceptance for redevelopment of the site was secured.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español