Remediation of LNAPL at Redevelopment Site – London, UK

A 99% reduction of LNAPL has been achieved within 2 months on this urban site with existing structures and buildings.Read More

Remediation of a Former Builder’s Yard, Bedfordshire, UK

Case study on the cost-effective treatment of TPH and PAH at a brownfield site in the UK. Read More

Remediation of Impacted Groundwater on a Busy Construction Site, UK

REGENESIS was asked to provide a remedial solution to mitigate against the off-site migration of the contaminated groundwater. We designed a PlumeStop barrier and was subsequently employed as subcontractor on the works. The barrier injections were made along the downgradient boundary of the site, targeting the groundwater in a gravel formation at 2 – 5m BGL. On this site, PlumeStop was co-injected with ORC-Advanced to enhance the aerobic biodegradation processes in the subsurface.Read More

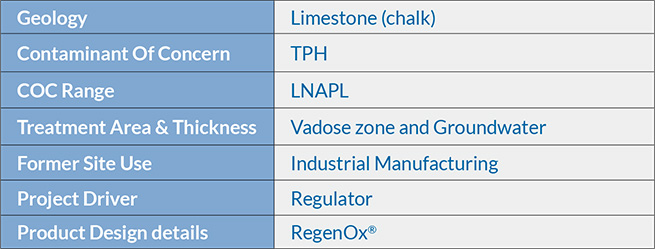

LNAPL Remediation in a Chalk Aquifer under a Residential Property

with BRD Environmental Ltd

Introduction

After completion of the redevelopment of former industrial land into residential properties, significant Total Petroleum Hydrocarbon (TPH) contamination was discovered in the groundwater and smear zone under the gardens and parking area. The TPH comprised diesel and heating oil, with up to 40mm of Light Non- Aqueous Phase Liquid (LNAPL) evident in the monitoring wells.

The original source of contamination (an above-ground storage tank) was removed during redevelopment; however, residual contamination had migrated into a lower chalk aquifer and after the discovery of LNAPL present within chalk fissures above the water table, remedial action was required.

Figure. 1 On site RegenOx® injections using a direct push injection rig

Figure. 2 Total TPH Concentration in Boreholes BH13 and BH14

Method

The two most highly contaminated boreholes, BH13 and BH14, were located in a back garden and a car parking space. As space was restricted and to minimise the impact of works on residents, an in situ remedial technique was deemed the only viable option.

RegenOx® is an In Situ Chemical Oxidation (ISCO) reagent capable of treating high concentrations of a broad range of soil and groundwater contaminants including both petroleum hydrocarbons and chlorinated solvents.

The alkaline nature of RegenOx enabled its use within the chalk aquifer without adverse matrix reaction.

The ability of RegenOx to deal with both LNAPL and dissolved phase contamination avoided the use of ‘pump and treat’ equipment onsite. This minimised both operational and disposal costs and negated the requirement for bulky equipment on the site. Applications were completed using a small direct- push injection rig (Figure 1). This meant that the resident’s parking area could be reinstated at the end of each working day, so that they could park overnight as usual.

The RegenOx injections were completed in three events at two week intervals during June and July.

Results

A 99% reduction of TPH concentrations occurred rapidly in boreholes BH13 and BH14 following the injection works, with LNAPL no longer observed on the site.

Conclusion

A short campaign of RegenOx applications at the site completely removed any LNAPL and reduced TPH concentrations by 99% in a chalk aquifer and regulatory closure was achieved within a short period.

At £55,000 for the product and application work, the project was extremely cost effective, avoiding the use of operational and disposal costs on the site. The in situ nature of the works avoided disturbing or inconveniencing residents living on the site.

Remediation of DNAPL in a Sandstone Aquifer at a Former Bleaching Mill

Successful treatment of DNAPL in a bedrock

An example of a successful remediation on a site already under construction. Through the use of 3DMe and close partnership with the Environmental Consultant, the number of wells could be minimised.

Read More

ISCO and Enhanced Aerobic Bioremediation during Residential Development

Excavation works minimised through the use of RegenOx, ORC-Advanced and ORC-Advanced Pellets, allowing development to continue without interruption.Read More

Pilot Study at Former Gasworks, Southeast England, UK

Pilot study results on a former gasworks site show that within 10 weeks of injecting PetroCleanze and ORC Advanced, significant mass reduction can be achieved. The pilot study is scalable to the entire site. Targeted remediation to reduce the contaminant mass in the most sensitive areas has the potential to dramatically reduce remediation costs for the developer.

Combined Remediation Approach Allows for Redevelopment, UK

Integrated treatment with In Situ Chemical Oxidation (RegenOx) and Dual Phase Vacuum ExtractionRead More

Enhanced Abstraction of Chlorinated Solvents using PetroCleanze

An extensive chlorinated solvent plume is treated by pump-and-treat augmented with PetroCleanze injections, followed by long term treatment via Enhanced Reductive Dechlorination using 3-D MicroemulsionRead More

Bioremediation of Chlorinated Solvents at an Operational Facility

HRC successfully degrades TCE plume, protecting sensitive receptor. With consultant: AECOM. Based on Richard Bewley’s presentation & article: ‘Meeting The Challenges For Bioremediation Of Chlorinated Solvents Posed At Operational Sites: A Comparison of Case Studies’ – AquaConsoil, 2015Read More

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español