In-situ approach results in cost-effective and successful treatment of TPH and PAH

Introduction

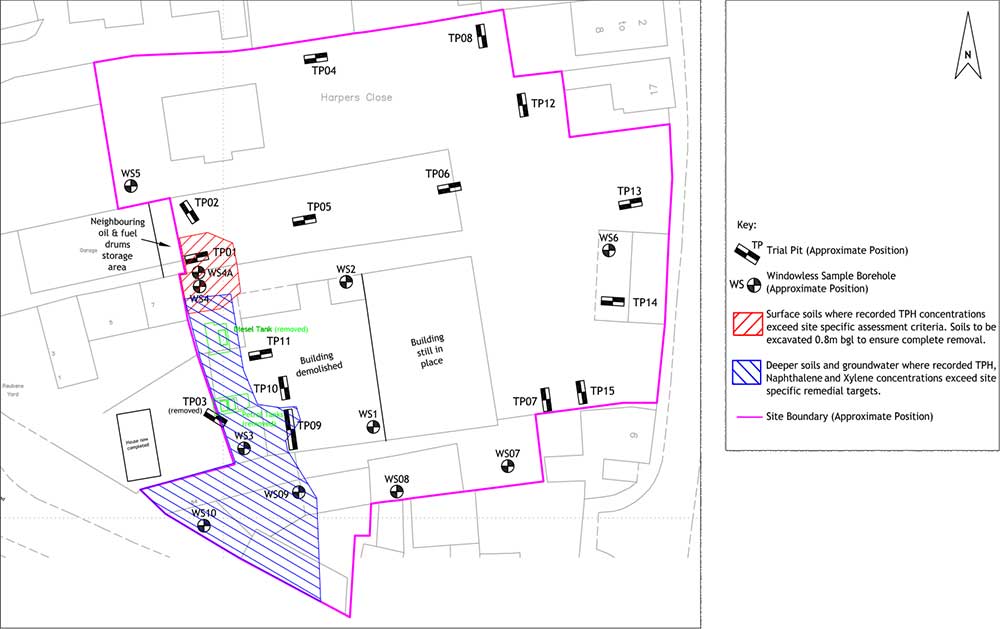

The site of a former builders merchant in Bedfordshire was undergoing redevelopment into residential properties. A site investigation found that underground storage tanks (USTs) had caused groundwater contamination in the southern part of the site and that surface spills had been identified as the cause of contamination found in the north (see figure 1). The USTs were removed in an earlier redevelopment phase.

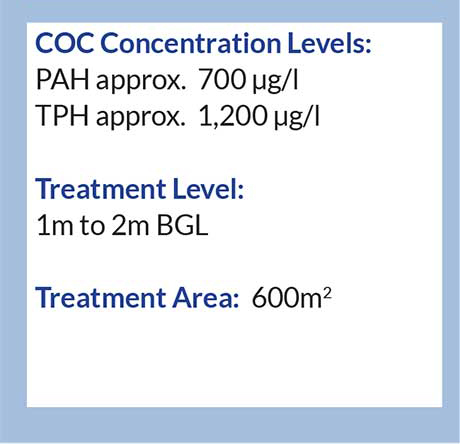

The dissolved TPH and PAH plume extended throughout 600m2 of the site, comprising concentrations of up to 1,200 μg/l.

Fig. 1 Site plan showing extent of contamination

The soils consist of made ground underlain by river terrace gravels, with a tight clay underneath. The groundwater level was found in a 0.5-1.0m layer in the based of the gravels. Although groundwater contaminations were fairly low, it was thought there was residual smear in the gravels, which could provide an ongoing secondary source (see figure 2).

It was determined that remediation was required and that excavation should be minimised. Pump and treat (P&T) was seen as unlikely to be successful, as the contaminant concentrations were relatively low, and the groundwater flow was intermittent and subject to poor re-charge. An in situ approach was therefore chosen, using RegenOx to provide in situ chemical oxidation (ISCO) of the smear zone and ORC Advanced being used to provide enhanced natural attenuation (ENA) of the residual groundwater contamination.

Design Methodology and Application

In the northern part of the site, a small excavation was made in the soils impacted by surface spills. ORC Advanced Pellets were placed in the base of the excavation to provide ENA of the groundwater contamination.

In the southern part, reagent injection was planned via wells on a grid pattern, to target the contamination in the permeable gravel layer. Three rounds of RegenOx were injected, with ORC Advanced added to the final application.

Fig. 2 Residual smear in the gravels

Application was challenging in part, because ISCO requires a high volume to ensure contact with the contamination. This lead to ‘daylighting’ (where product returns to the surface, see figure 3) in some locations where the permeabilities encountered were lower than expected. Therefore, the planned dose-per-injection round was reduced and the number of application rounds were increased, in order to maintain the overall treatment. In two areas of the site, the ORC Advanced treatment was achieved through application into slit trenches.

Fig. 3 Daylighting experienced in parts of the site

Results

Although validation is ongoing, the results to date show that the treatment has been successful in remediating the groundwater contamination:

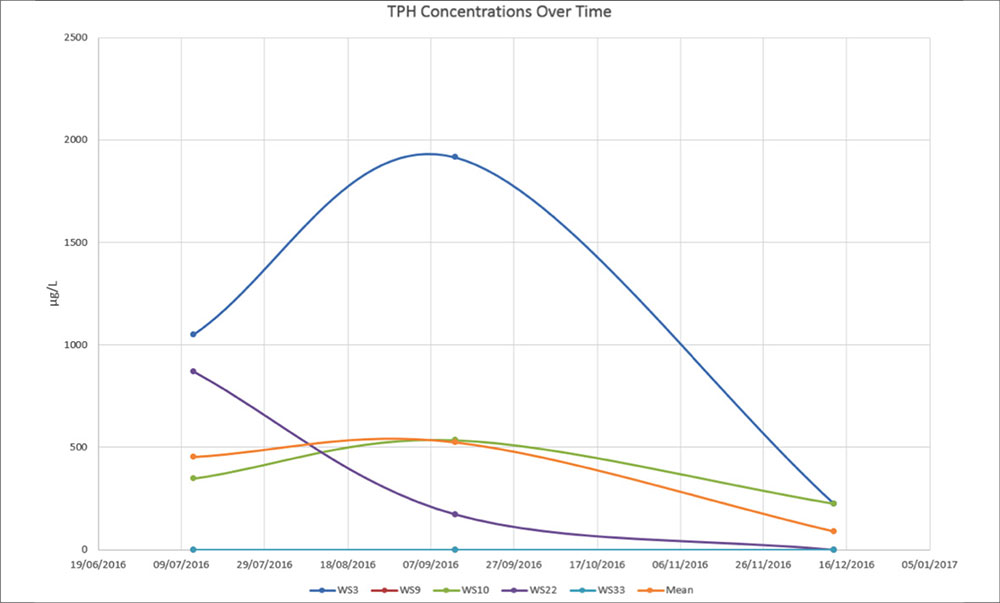

- The average TPH concentrations have shown a 80% reduction over 6 months, and these are continuing to reduce;

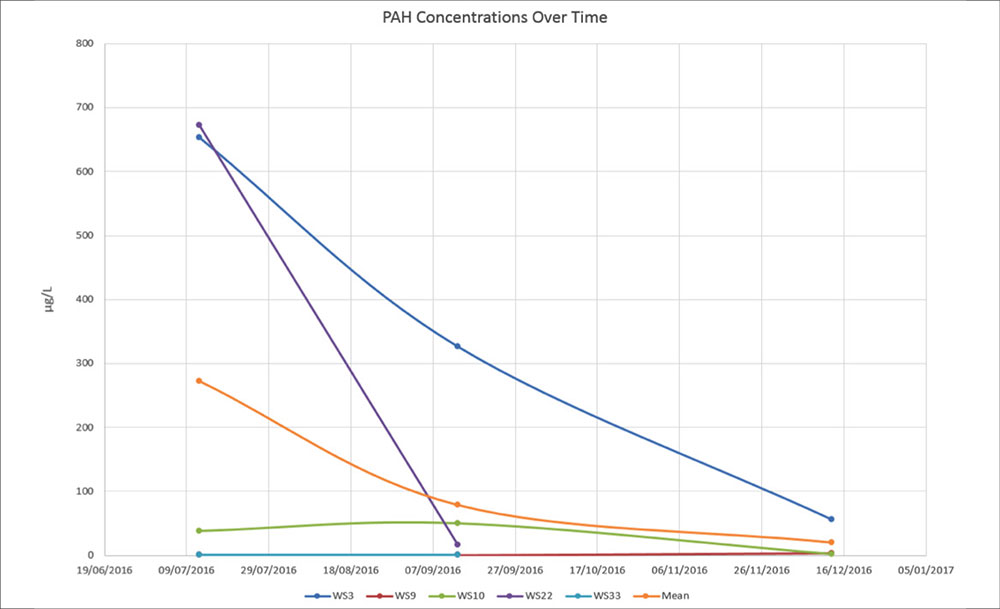

- For the PAH concentrations, a 93% reduction has been achieved over 6 months (see graphs below).

TPH concentrations over a 6-month period after application

PAH concentrations over a 6 month period after application

Conclusion

- The application works were completed over a few weeks, with only validation testing required thereafter. The remedial approach did not affect the construction programme onsite and allowed development to continue as planned;

- The treatment was highly cost effective, especially compared to the alternatives of extensive excavation or inefficient P&T;

- Because of the in situ approach, our injection team could be flexible and reactive in the field, so that when issues were encountered, we were able to amend our design and approach to ensure that the works were still done successfully, and within budget.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español