Design Focused Remediation of a UK Defense Manufacturing Site

The remediation injection works, completed by REGENESIS between the demolition and construction phases, minimised impact on the site redevelopment programme.Read More

Successful Remediation of a Large Scale Chlorinated Solvent Plume

A single injection of 3-D Microemulsion on a wide injection grid remediates redevelopment site.Read More

Bioremediation of Petroleum Hydrocarbons, Oxfordshire, UK

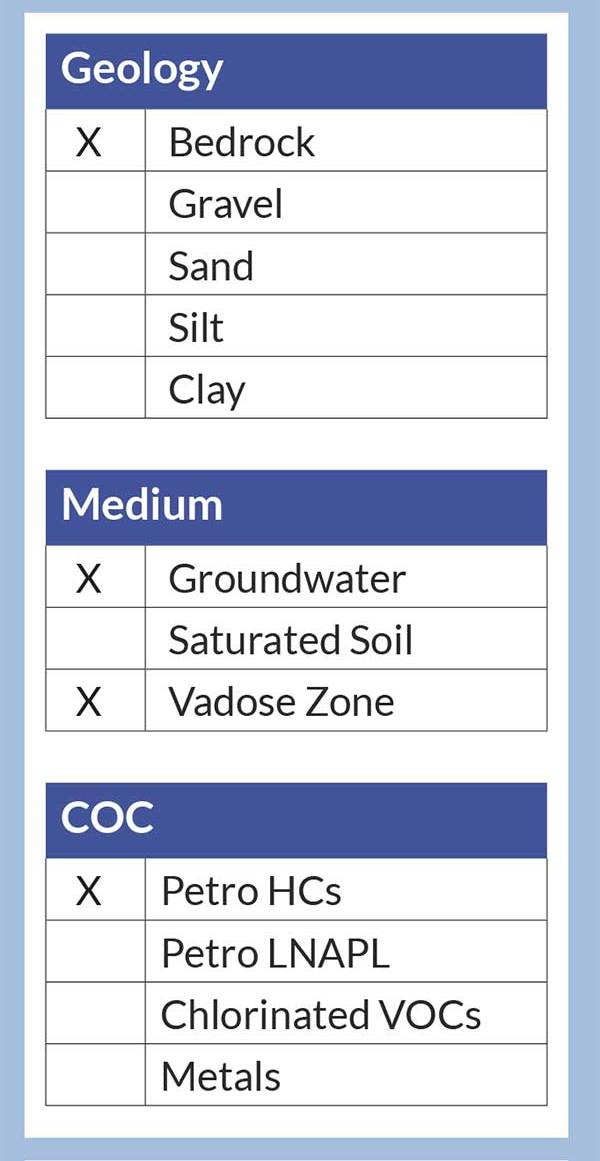

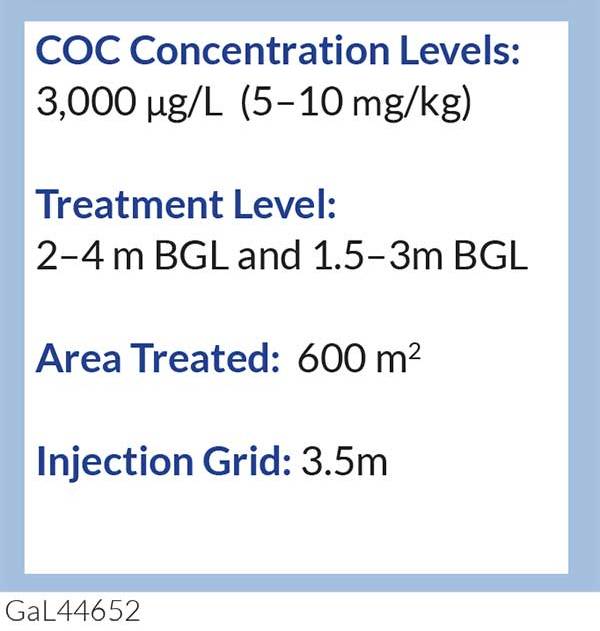

Summary

Following a site investigation (SI) and the removal of 8 underground storage tanks at a former petrol filling station, it became clear that the groundwater and soils beneath the site were grossly impacted by petroleum hydrocarbons (TPH). The geology comprised of made ground underlain by weathered limestone at 1m BGL. Though the groundwater concentrations were relatively low (3,000 μg/L TPH), the high sorbed mass in the soils (up to 10,000 mg/kg) was of concern. Though the remediation strategy did allow for the excavation and treatment of the weather material, due underground utilities most of the impacted material could not be excavated for health and safety reasons, without diverting the existing underground infrastructure.

REGENESIS and the Environmental Consultant formulated a remediation strategy comprising of partial excavation of impacted material (where allowed) and in-situ enhanced aerobic bioremediation of the groundwater for betterment of underlying conditions. All to be validated by groundwater monitoring to demonstrate contaminant mass reduction across the site.

Treatment

An ORC-Advanced® slurry was injected across 54 No. wells installed into the underlying bedrock with specific doses in the northern and southern areas of the site to target where TPH had been recorded during the SI. ORC-Advanced was applied across the entire plume, in order to provide enhanced aerobic biological degradation of the dissolved phase for 12 months from a single injection.

What’s Special?

- A remediation strategy where validation of the groundwater (not soil) achieved site sign-off, resulting in quick site closure.

- The in situ remediation allowed for injection adjacent to underground utilities without damaging them, avoiding the need for excavation or re-routing infrastructure.

Petroleum Contaminated Groundwater Treatment, West London, UK

Installation of ORC-Advanced barrier successfully reduced the contaminant influx onto the site, allowing for site redevelopment without any disruption Read More

Remediation of Hexavalent Chromium in Bedrock at Former Saw Mill

Bedrock chrome VI contamination treated to non-detect levels in 2 months, expediting regulatory sign-off and unlocking the site for redevelopmentRead More

Hotspot Treatment of Petroleum Hydrocarbons – North West, UK

Phased, in situ treatment with PetroCleanze and ORC-A Socks allows main contractor to keep programme on trackRead More

PetroCleanze Increases Efficacy of Pump and Treat System – Reading, UK

Treatment example of LNAPL and smear zone in bedrock. PetroCleanze enhanced the efficacy of the existing P&T system, reducing P&T costs onsite.Read More

Hexavalent Chromium Barrier Treatment Protects River

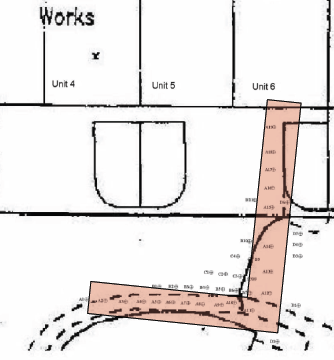

Summary

w_Reg_20916_MRC_8_inj-rig_UKOn an industrial estate in Ravensthorpe, West Yorkshire, a leak from a storage tank in a chrome-plating works, had resulted in contamination of the underlying groundwater. The contamination was found to be migrating off-site, under neighbouring properties, towards a nearby river. Regenesis was employed to design and install a barrier to protect the river for a guaranteed 12 months in order to allow the building to be cleared of other tenants prior to demolition and source removal.

Design & Application

Metals Remediation Compound (MRC) was used to immobilise the contamination by reducing soluble hexavalent chromium into solid, non-hazardous trivalent chromium, which settled out of the groundwater. The MRC was injected in an ‘L’ shaped barrier through the apron and road outside of the industrial unit. The corner of the ‘L’ consisted of three rows of direct push injection locations, in order to provide a wide treatment zone where maximum contaminant influx would occur. The MRC was applied using direct push injection in gravels, from the top of the groundwater at 5 m BGL to 12 m BGL (rock-head).

What’s Special?

- Within weeks of application, the barrier prevented the movement of hexavalent chromium contamination towards the river. Concentrations of 10,000 μg/L Cr(VI) were reduced by >98% to <200 μg/L 5m downgradient of the barrier and non-detect at the river.

- Regenesis provided a warranty on the barrier for a period of 12 months after the application, however the MRC barrier would remain effective between 2 to 3 years.

- The controlled-release mechanism of MRC meant that offsite receptors were protected for an extended period from a single, low-cost injection.

In Situ Remediation of PCE and DNAPL at Active Industrial Drycleaners

A highly sustainable form of remediation with estimated savings likely to exceed £500,000. Read More

Hexavalent Chromium Remediation at Former Saw Mill

Summary

REGENESIS were retained to carry out the remediation design and site application works to treat groundwater impacted with hexavalent chromium (Cr VI) on the site of a former saw mill in the United Kingdom, Europe. Metals Remediation Compound® (MRC) and 3-D Microemulsion® (3DMe) were applied into the groundwater to provide rapid reduction and immobilisation of the CrVI present. Groundwater samples collected 2 months after application were analysed for CrVI , returning non-detect results.

Treatment

Due to the ground conditions of weathered limestone, treatment was carried out via pre-installed treatment wells at 5 m spacing in the source area and 6 m in the barrier. MRC and 3DMe were co-applied into these wells to target the source area of contamination and to install a reactive barrier at the down-gradient edge of the site to protect a nearby watercourse. MRC and 3DMe provide a powerful combination of wide distribution and strong reducing and immobilising properties.

What’s Special?

- REGENESIS’ injection team completed the site works ahead of schedule to allow the groundwork contractor to prepare the site for housing development.

- The use of MRC and 3DMe allowed for wide spacing of the injection wells and therefore lower drilling costs.

- The treatment approach achieved rapid reductions from up to 15,000 μg/L of Cr(VI) to non-detect within two months, expediting regulatory sign-off and unlocking the site for redevelopment

Technology Descriptions

Metals Remediation Compound (MRC) removes metals such as dissolved Cr(VI) from groundwater via in situ immobilisation (precipitation and/or sorption to soil particles).

3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory-emulsified product..

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español