Safe and Simple Excavation Application Provides Long-Term Treatment

Summary

During the demolition and redevelopment of a former petrol filling station, an underground storage tank was removed. The tank had been used for the storage of diesel and had leaked into the surrounding soils and groundwater. The impacted soils were excavated and removed to a waste management facility. The groundwater within the excavation was impacted with dissolved phase hydrocarbons and required further treatment.

Regenesis provided the remediation contractor with a remedial design for the application of ORC Advanced Pellets to treat the residual contamination within the groundwater in and around the open excavation.

Treatment

ORC Advanced Pellets were applied into the groundwater, in the base of the excavation. This was completed by placing them in an excavator bucket and spreading evenly across the area. By using the pelletised version of ORC Advanced, there was no need for mixing or application using pumps and the potential for dust creation was minimised.

The pellets take only minutes to apply and yet provide a controlled release of oxygen into the groundwater for a period of 9-12 months from a single application. The ORC Advanced stimulates the growth of an aerobic biomass which accelerates the biological degradation of dissolved phase hydrocarbon contamination.

What’s Special?

- The use of ORC Advanced Pellets meant that the contractor could backfill the excavation and continue the build programme with minimal disruption.

- The remediation then continued in situ with no need for physical plant taking up valuable space or requiring maintenance.

- ORC Advanced Pellets provide an effective long-term treatment of residual dissolved phase contamination though a very easy, safe and rapid application process.

Product Description

ORC Advanced Pellets (ORC-A Pellets) are a pelletised version of REGENESIS’ widely-used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletised, dry application material minimises airborne dust while eliminating the need for specialised equipment and spray water required for powder-slurry applications. ORC Advanced Pellets are approximately 3-10 mm in size.

Combined RegenOxTM and ORC Advanced® Application Treats TPH and BTEX

Introduction

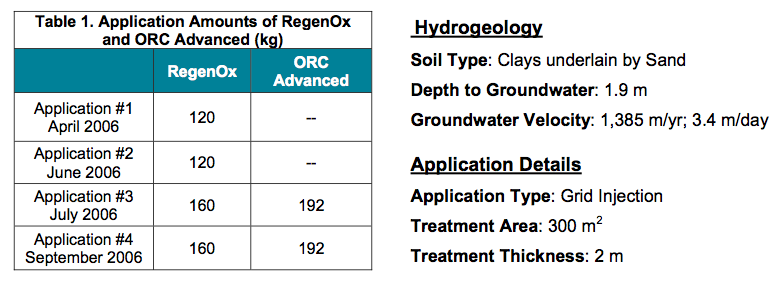

Operations at a former car dealership resulted in petroleum hydrocarbon contaminated soil and groundwater. In the source well SB7, groundwater concentrations of total petroleum hydrocarbons (TPH) had increased to 250 parts per million (ppm) and concentrations of benzene, toluene, ethylbenzene, and xylenes (BTEX) were present at more than 400 ppm. In order to reach the TPH site specific target level (SSTL) of 19.2 ppm, a combined remedial approach using chemical oxidation and enhanced aerobic bioremediation was implemented. Injections of RegenOxTM and ORC Advanced® were applied in four separate injection events (Table 1). The combined approach was designed to treat the high concentrations and promote aerobic bioremediation of any remaining residual contamination.

Remediation Approach

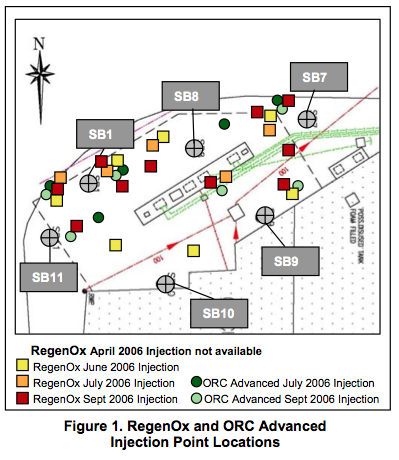

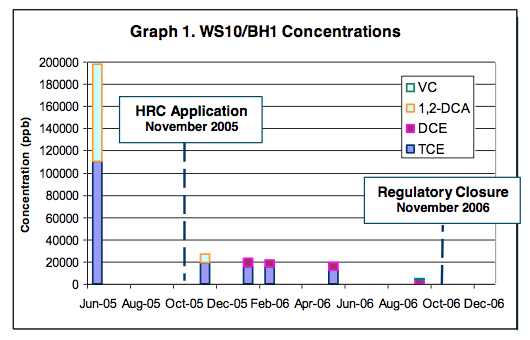

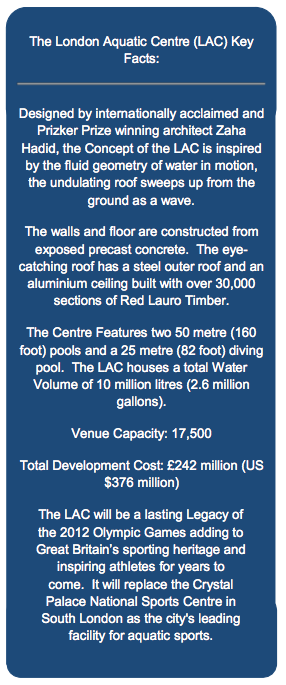

The remedial objective was to reduce high concentrations of TPH to below the SSTL of 19.2 ppm. RegenOx was applied in April 2006 and June 2006 across the plume (Figure 1). Both RegenOx and ORC Advanced were applied separately in July 2006 and September 2006. (Table 1)

In Situ Treatment Results

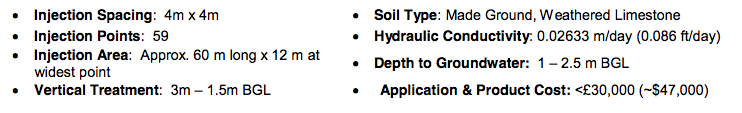

Shortly after the initial RegenOx chemical oxidation treatment, TPH was reduced by an average of 67% (Graph 1). As is typical following the first chemical oxidation application, contaminant rebound occurred after approximately one month. This is primarily a result of rapid desorption of sorbed phase contaminants from soil into groundwater and the 30 day longevity of RegenOx. Three follow up RegenOx injections were applied to continue treatment and eliminate the remaining contamination. Additionally, two ORC Advanced injections were performed to provide a long-term (12 months on average) oxygen source for enhanced aerobic bioremediation.

Shortly after the initial RegenOx chemical oxidation treatment, TPH was reduced by an average of 67% (Graph 1). As is typical following the first chemical oxidation application, contaminant rebound occurred after approximately one month. This is primarily a result of rapid desorption of sorbed phase contaminants from soil into groundwater and the 30 day longevity of RegenOx. Three follow up RegenOx injections were applied to continue treatment and eliminate the remaining contamination. Additionally, two ORC Advanced injections were performed to provide a long-term (12 months on average) oxygen source for enhanced aerobic bioremediation.

RegenOx was effective at reducing TPH to below the SSTL in all wells, excluding SB7 (Graph 1) which was located within the source area. However, a reduction of 95% occurred in SB7 within two weeks of the initial RegenOx injection. Rebound was observed in this area throughout the treatment, indicating that sorbed phase TPH was more prevalent around this well. RegenOx reduced the overall TPH loading of the soils and maintained TPH concentrations in groundwater to below 60 ppm. The ORC Advanced applications are expected to further TPH reduction in this area via enhanced aerobic biostimulation beyond the length of the monitoring program.

Conclusion

As a result of the RegenOx applications, concentrations were reduced quickly and cost-effectively within weeks of the injections. It is expected that the remaining concentrations above the SSTL in Graph 1 will be reduced as ORC Advanced continues to release oxygen. Successful closure was achieved due to the overall reduction in TPH concentrations, the observed reduction in contaminant concentrations in the source area, and the expected future reductions from the application of ORC Advanced.

Enhanced Reductive Dechlorination of Chlorinated Solvents in Groundwater Enables Development of Contaminated Site

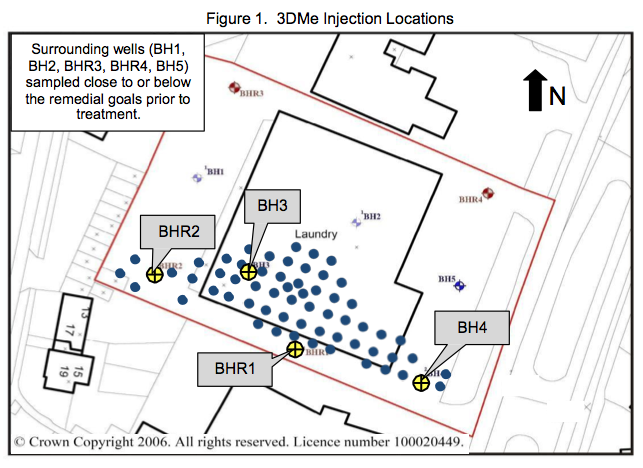

A former dry cleaning site was scheduled for redevelopment into residential properties. Site investigations revealed that past laundry operations had resulted in chlorinated solvent contamination within the groundwater. Concentrations of tetrachloroethene (PCE) were increasing with little to no measureable daughter products being observed, indicating a lack of reductive dechlorination occurring in the subsurface. ENVIRON UK Ltd. completed a Detailed Quantitative Risk Assessment (DQRA) for the contaminants of concern on the site and liaised with the regulatory authorities in order to agree on site specific target levels (SSTL) for the remediation project. Anaerobic biostimulation using an electron donor was chosen to biologically reduce chlorinated solvent concentrations. The majority of contamination was delineated around wells BHR1, BHR2, BH3, and BH4. Within the most impacted well, BH4, the total chlorinated solvent contamination had reached approximately 4,000 micrograms per litre (μg/L).

3-D Microemulsion (3DMe®) Application

3-D Microemulsion (3DMe), supplied by Regenesis Ltd., uses a 3-stage donor release profile allowing for the immediate, mid-range and long-term release of hydrogen into the groundwater. The hydrogen is used to increase the mass and activity of indigenous microorganisms performing reductive dechlorination. 3DMe was mixed with water to form a microemulsion for injection. Approximately 1,250 kg (2,750 lbs) of 3DMe was mixed with water at a ratio of 20 parts water to 1 part 3DMe and injected using the grid design shown in Figure 1.

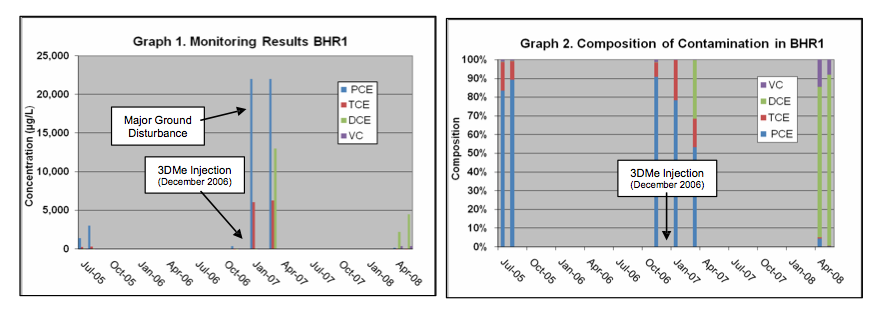

BHR1 – Southern Plume Boundary

PCE in well BHR1 (Graph 1) reached concentrations of up to 3,000 μg/L prior to treatment. Approximately one month after the 3DMe injection and following the removal of a concrete slab and excavation works, an increase in PCE and trichloroethene (TCE) concentrations was observed, peaking at 22,000μg/L and 6,300μg/L, respectively. This was attributed to an influx of chlorinated solvents caused by a physical disturbance and a rain event which mobilised contamination from the capillary fringe zone. Despite these peaks, PCE and TCE concentrations declined significantly to approximately 20 μg/L at 17 months post-injection. Concentrations of DCE increased to a peak of 13,000 μg/L as PCE and TCE were dechlorinated, followed by a decline to below 5,000 μg/L. Vinyl chloride (VC) was also detected at approximately 400 μg/L. The total chlorinated solvent mass was reduced by over 80% in 17 months.

The chlorinated solvent contamination in BHR1 comprised of 90% PCE prior to the application (Graph 2) with little evidence of significant reductive dechlorination occuring. Following the injection of 3DMe, concentrations of PCE and TCE declined to non-detect with the sequential appearance and degradation of daughter products indicating the decline in contaminant concentrations was due to enhanced reductive dechlorination.

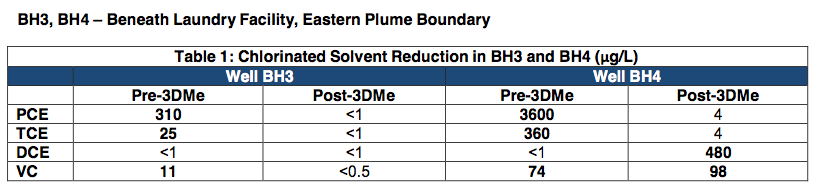

BH3, BH4 – Beneath Laundry Facility, Eastern Plume Boundary

Prior to the 3DMe application, concentrations of parent products PCE and TCE were stable indicating a low rate of dechlorination was occurring. Within three months of the 3DMe injection, concentrations of PCE and TCE were reduced to near non-detect levels while DCE and VC concentrations sequentially increased. At ten months post- injections, all contaminants of concern in well BH3 had reached non-detect levels and continued reduction was observed in well BH4. It is anticipated that the long-term release profile of 3DMe will maintain an anaerobic environment for further reduction in this area.

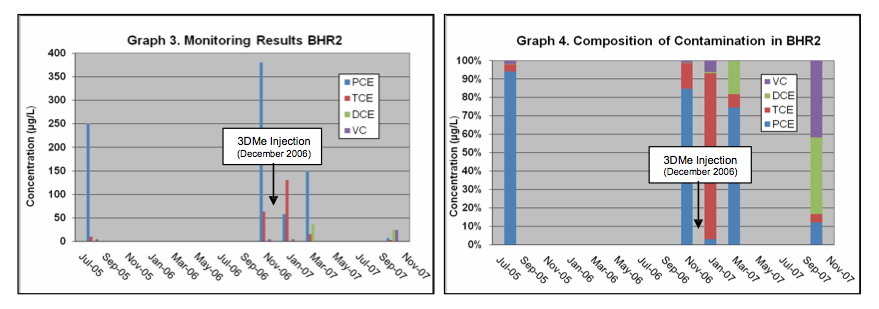

BHR2 – Western Plume Boundary

Well BHR2 (Graph 3) contained almost 400 μg/L total chlorinated solvents prior to the 3DMe injection. Within one month of the application, PCE was reduced to 4 μg/L while TCE concentrations initially rose to approximately 130 μg/L and then declined to approximately 15 μg/L. The reductive dechlorination sequence continued as DCE increased to 35 μg/L then declined. Concentrations of VC remained reduced. An analogous spike in PCE concentration was observed similar to that observed in well BHR1 following the concrete slab removal. It is notable that the spike comprised the parent product PCE whilst daughter product trends were not notably affected. This would be consistent with an influx of fresh contamination following the disturbance, while on-going degradation of the original contamination proceeded. Following this peak, concentrations of total chlorinated solvents declined to below 60 μg/L at 22 months post-injection.

Before the application of 3DMe, the chlorinated solvent contamination in BHR2 comprised of up to 95% PCE (Graph 4). Following the injection of 3DMe, the PCE concentration reduced by 98% and the TCE declined by 95% within 22 months. As seen in well BHR1, the sequential appearance and degradation of daughter products was observed indicating that enhanced reductive dechlorination was occurring.

CONCLUSION

Prior to remediation work commencing, concentrations of PCE in the groundwater were increasing presumably due to ongoing desorption from impacted soils and infiltration of the capillary fringe zone. Minor concentrations of TCE and DCE indicated a lack of reductive dechlorination was occurring and enhanced anaerobic biostimulation was needed in order to reach the SSTLs. Within one month of the 3DMe application, strong evidence of reductive dechlorination was observed as PCE and TCE declined by more than 96% to non-detect levels and breakdown products DCE and VC increased, then declined.

Chlorinated solvent concentrations throughout the plume were reduced towards the cleanup goals within ten months of the 3DMe application, representing a total contaminant mass reduction of more than 80%, despite influx of additional contamination. Further reduction is expected as 3DMe continues to enhance the reductive dechlorination process allowing for continued treatment of the remaining chlorinated solvents. Redevelopment of the site has since been completed with the appropriate regulatory authority sign off in place. The remediation was achieved through a single injection event costing less than £30,000 for 3DMe and application fieldwork combined.

High Concentrations of Chlorinated Solvents Reduced to Non-Detect Allowing for Site Closure

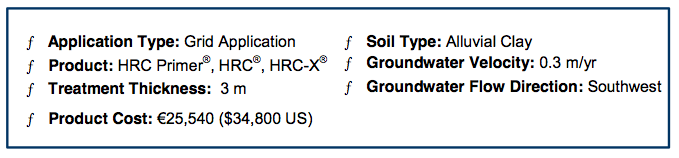

The subject site has been used for the manufacture of industrial switchgear assemblies and warehousing since the 1970s. A subsurface investigation revealed a highly localized plume near WS10 with significant groundwater concentrations of trichloroethene (TCE) at 260 parts per million (ppm) along with its breakdown product cis-1,2- dichloroethene (cDCE). A site specific target level (SSTL) was established for TCE (1.0 ppm) and remedial action began with an in situ injection of Hydrogen Release Compound (HRC®). The product was chosen over other remedial strategies since the application would not disrupt on-site operations and did not require long-term maintenance.

Remediation Approach

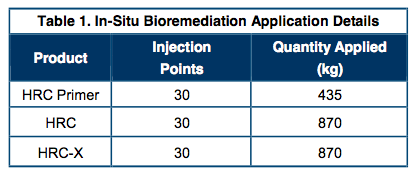

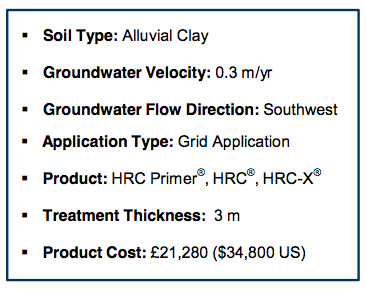

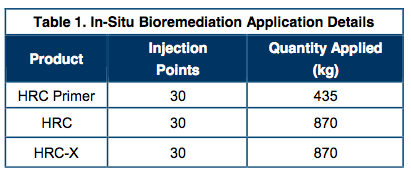

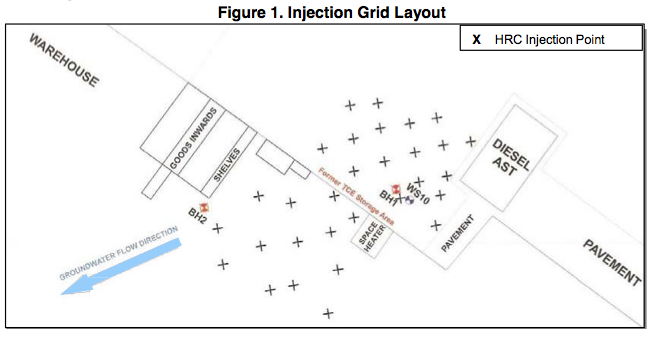

The remediation objective was to reduce concentrations of TCE to below the SSTL of 1.0 ppm. A combined approach using HRC Primer®, HRC and extended release, HRC-X®, was applied using a grid injection layout (Figure 1). HRC Primer was initially injected to quickly establish reducing conditions within the aquifer. The injection of HRC would sustain anaerobic conditions over the next 18 months while the addition of HRC-X would continue releasing hydrogen for approximately 5 years. Two new wells were installed to monitor the progress of remediation – BH1 and BH2. Well BH1 replaced future monitoring in WS10 while BH2 was installed downgradient. Sampling of both wells indicated a hot spot at BH1 and no elevated level of contamination in BH2.

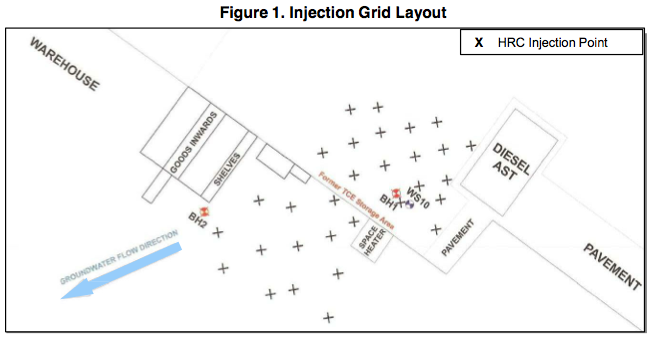

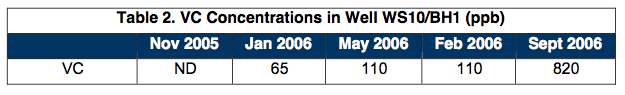

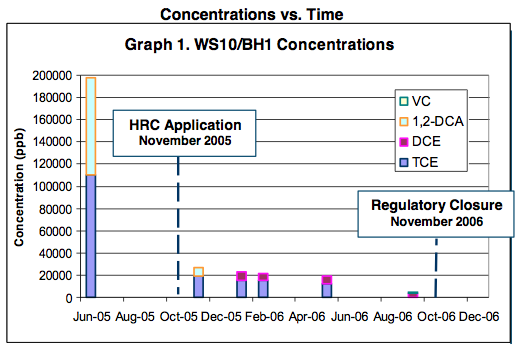

Monitoring results immediately following the HRC injection (November 2005) revealed TCE was present at BH1 but not at BH2 indicating no migration off-site was likely to occur. Breakdown products 1,1-dichloroethene (1,1-DCE), trans-1,2- dichloroethene (tDCE), and cDCE were present for the first time demonstrating a reductive dechlorination process had been established as a result of the HRC application. By January 2006, trace concentrations of vinyl chloride (VC) were detected for the first time indicating that complete dechlorination was occurring in the subsurface.

In September 2006, sampling results indicated TCE levels were below the SSTL of 1.0 ppm (Graph 1). Breakdown products continued to be detected however all were on a reducing trend.

CONCLUSION

Within 10 months, total chlorinated compounds in Well WS10/BH1 were reduced from 198 to 4.3 ppm, a 98% reduction. The TCE remedial goal was reached using one combined application of HRC Primer, HRC and HRC-X. The consultant and environmental agency agreed that the remaining chlorinated solvents would continue to reduce and no further action was needed. A request for site closure was granted in November 2006.

High Levels of Chlorinated Solvents Reduced to Non-Detect; Site Receives Closure

CASE SUMMARY

The subject site has been used for the manufacture of industrial switchgear assemblies and warehousing since the 1970s. A subsurface investigation revealed a highly localized plume near WS10 with significant groundwater concentrations of trichloroethene (TCE) at 260 parts per million (ppm) along with its breakdown product cis-1,2-dichloroethene (DCE). A site specific target level (SSTL) was established for TCE (1.0 ppm) and remedial action began with an in-situ injection of Hydrogen Release Compound (HRC®). The product was considered an effective approach since it did not require long-term maintenance and produces a limited amount of waste.

REMEDIATION APPROACH

The remediation objective was to reduce concentrations of TCE to below the SSTL of 1.0 ppm. A combined approach using HRC Primer®, HRC and extended release, HRC-XTM, was applied using a grid injection layout (Figure 1). HRC Primer was initially injected as a mechanism to establish reducing conditions within the aquifer. The injection of HRC promoted a continued supply of hydrogen to the anaerobic environment over the next 2 years while HRC-X would provide an electron donor for approximately 5 years. Two new wells were installed to monitor the progress of remediation – BH1 and BH2. Well BH1 replaced future monitoring in WS10 while BH2 was installed downgradient.

RESULTS

Monitoring results immediately following the HRC injection (November 2005) revealed TCE was present at BH1 but not at BH2 indicating no migration off-site was likely to occur. Breakdown products 1,1-dichloroethene (1,1- DCE), trans-1,2-dichloroethene (tDCE), and DCE were present for the first time demonstrating a reductive dechlorination process had been established as a result of the HRC application. By January 2006, trace concentrations of vinyl chloride (VC) were detected for the first time indicating that complete dechlorination was occurring in the subsurface.

In September 2006, sampling results indicated TCE levels were below the SSTL of 1.0 ppm (Graph 1). Breakdown products continued to be detected however all were on a reducing trend while VC continued to increase as a result of the reduction.

CONCLUSION

Within 10 months, total chlorinated compounds in Well WS10/BH1 were reduced from 198 to 4.3 ppm, a 98% reduction. The TCE remedial goal was reached using one combined application of HRC Primer, HRC and HRC- X. The consultant and environmental agency agreed that the remaining DCE and VC would continue to reduce and no further action was needed. A request for site closure was granted in November 2006.

Rapid Reduction of Petroleum Hydrocarbons using ORC Advanced® allows for Redevelopment of Site

Summary

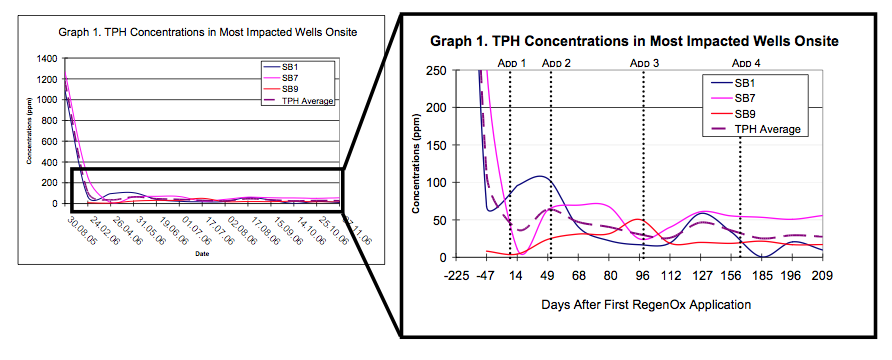

Remedial works at the Former Lama Petroleum site were undertaken in late 2008 as part of the ongoing redevelopment of the Fresh Wharf Estate in Barking UK. The site was to be developed for light industrial use, however, historical oil mixing handling and storage activities performed on the site had resulted in TPH and PAH contamination in the groundwater.

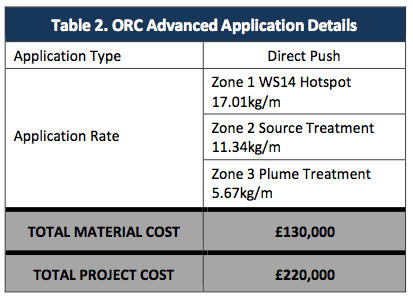

Site investigation works suggested the presence of an approximately 1,000m2 source area in thenorthwestern portion of the site, as well as a downgradient plume area, estimated to be in the region of 6,000m2 extending towards the Handtrough Creek. Phase separated hydrocarbons were detected in the source area where the former above ground storage tanks had been located prior to decommissioning circa 2003. In the downgradient plume area, the maximum dissolved phase TPH concentration was 1,100μg/L (Monitoring Well BH102) and located adjacent to Handtrough Creek.

Remedial Strategy

The remedial objective was to reduce dissolved phase concentrations of Total TPH and PAH in groundwater to the agreed remedial target level of 110μg/L, within 12 months of treatment. A trigger level for further remediation was set at 200μg/L, equating to an 80% contaminant concentration reduction within 42 weeks post treatment. If the trigger TPH concentration was not achieved within 42 weeks after treatment, further options would be undertaken.

The original assessment of remedial options identified that a combination of Pump and Treat (P&T) to target free product in the source area and ORC Advanced® treatment in the groundwater plume would represent the most time‐efficient and cost‐effective remedial solution for the site. However, trial pits advanced in the source area during site clearance works

determined that free product was not present in the groundwater, but was present in discrete bands within the unsaturated made ground. Following this observation, excavation to remove the most impacted soils in the source area was determined to be the most suitable approach and P&T was discarded as an option.

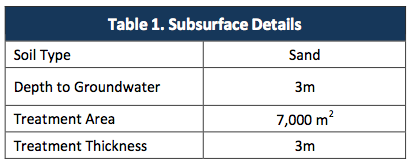

Soil removal works were undertaken at the site in October 2008. ORC Advanced treatment in both the source and plume areas was undertaken in October and November 2008. ORC Advanced was applied using three direct push injection rigs and a separate mixing and pumping unit. The rods were driven to 6mBGL and the ORC Advanced was applied over the impacted saturated zone as the rods were slowly withdrawn to 3mBGL. The application included a total of 813 injection points over 19 drilling days. The dose rates were varied to match the different contaminant concentrations and conditions encountered across the site (Tables 1 & 2). Vibro‐piling works were completed across the site at the same time as the ORC Advanced was being applied and were unimpeded by the direct push equipment.

Results

Following the injection of ORC Advanced, a slight increase in the dissolved phase contaminant concentrations was observed due to the site disturbance from injection and piling works. Both TPH and PAH concentrations then rapidly decreased to below the site specific remedial target values and remained low over the monitoring programme. A 99% reduction in the groundwater concentrations of TPH and PAH was achieved with no rebound. Monitoring results are presented below for well BH102, which was located on the southern site boundary, adjacent to Handtrough Creek.

Conclusion

Following the application of ORC Advanced, TPH and PAH concentrations were rapidly reduced and maintained below the site specific target values without contaminant rebound. The works were completed safely and efficiently and did not hinder the ongoing construction works occurring simultaneously at the site. The low final contaminant concentrations and the lack of rebound resulted in regulatory acceptance of the remediation and development works were completed.

London Olympic Park Environmental Cleanup Uses Bioremediation Technology ORC Advanced® to Treat Hydrocarbons and Expedite Construction

The multi-billion dollar development of the 500 acre London 2012 Olympic Games Park has been one of the largest Brownfields regeneration projects in recent years. Located in Stratford in East London, the site was formerly an industrial estate with uses including: chemical, fertilizer, engineering works, landfills and depots leaving a legacy of soil and groundwater contamination.

The Olympic Delivery Authority (ODA) set strict deadlines for the Olympic facility construction projects. The development included the construction and refurbishment of 16 new major stadia and sports facilities. More specifically, the subsurface foundations for the London Aquatic Centre (LAC) were to be completed by the 27th July 2009 (exactly three years before the London 2012 Olympic Games Opening Ceremony).

The LAC site was contaminated with petroleum hydrocarbons from lubricating oil as a result of historic operations. The first stage of remediation began in November 2007 using dual-phase vacuum extraction (DPVE) to remove the LNAPL, however due to the strict ODA deadlines and integration with construction programmes (starting in April 2008) prolonged use of DPVE was not practical to remediate the dissolved phase hydrocarbon plume. An in situ

solution became the only viable option.

In Situ Enhanced Bioremediation, a widely accepted and well understood natural biodegradation process was chosen to cleanup this portion of the site. This approach

utilizes indigenous microbes to aerobically biodegrade petroleum hydrocarbons in-place. The actual process is facilitated using an injectable, Advanced Oxygen Release Compound (ORC Advanced®). Upon hydration and injection, this powder-like material accelerates aerobic bioremediation by releasing molecular dissolved oxygen for periods up to 12 months on a single application. Without this valuable oxygen supply, the required aerobic bioremediation processes either cease or proceed at very slow rates

The patented Controlled-Release Technology (CRTTM) in ORC Advanced allows for an efficient, long-term release of oxygen which provides optimal conditions for sustained aerobic biodegradation. CRT also saves time and money during implementation by eliminating the need for multiple oxygen release compound applications.

Additionally, ORC Advanced® was applied at the LAC site using direct-push injection. This application approach is highly efficient as it requires no permanent well installation, above-ground piping or mechanical equipment and after application, no operational costs or further site disturbance. Remedial objectives or the Olympic Games Aquatic Centre were satisfied and redevelopment of the site was unhindered by the ongoing in situ remedial work. More importantly, the construction-phase was completed according to the ODA set deadlines.

REGENESIS is proud to have supported environmental consultants, remediation contractors and regulators in successfully delivering the multi-billion dollar, award winning, remediation for The London 2012 Olympic Games.

Combined Remediation Approach – Dual Phase Vacuum Extraction with In Situ Chemical Oxidation

Introduction

When redevelopment of an old service station was proposed, site investigations revealed a significant petroleum hydrocarbon impact within the soil and groundwater. The subsurface contamination threatened to derail the redevelopment program and a rapid remediation strategy was needed to reduce concentrations to acceptable levels. Geo2 Remediation was contacted to remediate the site in order to allow safe development for luxury residential properties while ensuring no impact to local protected controlled waters.

Figure 1. Successful Site Remediation Leads to Luxury Residence Redevelopment

Project Background

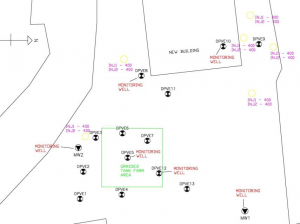

Geo2 Remediation carried out the treatment of a former service station following historic leakage from underground storage tanks (USTs). The tanks had been removed prior to the beginning of the site investigation. Free product was discovered at the surface of the saturated zone and elevated concentrations of total petroleum hydrocarbons (TPH) were observed within the groundwater. Concentrations of TPH as high as 290 mg/L were discovered within the source area.

In Situ Physical Remediation

Geo2 Remediation installed a dual phase vacuum extraction (DPVE) system, designed to rapidly remove phase separated product identified on the surface of the groundwater. The DPVE system began treatment in September 2007. Thicknesses of free product up to 50mm, identified around the former tank farm, were removed within 1 month of commencing treatment. Within the groundwater, TPH concentrations were reduced to between 300 mg/L and 150 mg/L over a 5-month monitoring period. In order to increase the efficiency of the DPVE system, Geo2 augmented the physical treatment system with RegenOx to provide a rapid reduction in soil and groundwater concentrations and allow redevelopment to proceed on schedule.

Combined In Situ Physical Remediation and Chemical Oxidation

Geo2 Remediation applied RegenOxTM, a safe and easy to apply proprietary in situ chemical oxidation (ISCO) designed to provide rapid concentration reduction of contaminants without a violent exothermic reaction or other handling difficulties common to ISCO reagents. RegenOx was injected into the subsurface around the dissolved phase impact following DPVE system shutdown using a direct-push injection rig. Two applications were completed within one week of each other using a modest dose of 326 kg RegenOx to achieve sorbed-phase desorption and partial chemical oxidation of the residual hydrocabons. The DPVE system was then restarted to remove the resulting desorbed contamination and partially oxidised hydrocarbon species from the groundwater – this enabled the Reagent requirements to be kept to a minimum (i.e. partial contaminant oxidation rather than full contaminant oxidation) whilst capitalising on the use of the DPVE system already in place. The total cost of the RegenOx application – including all fieldwork – was approximately £ 5,000, the cost of one month’s DPVE operation at the site.

RegenOx® Basics

RegenOx® is a proprietary two-part chemical oxidation product developed and sold by Regenesis for in situ groundwater treatment. It combines the use of a controlled-release percarbonate-based oxygen compound with a proprietary multi-part catalyst to generate surface-mediated free-radical generation and contaminant oxidation (e.g. perhydroxyl radical, hydroxyl radical and superoxide radical), with reactive power comparable to that of Fenton’s reagent but with greatly facilitated handling and subsurface delivery / longevity (up to 30 days). This provides an effective contaminant oxidation reaction without violent exothermic reaction, and can therefore be handled using a wide range of standard field equipment (e.g. direct push injection rigs) or applied directly to excavations. Furthermore, it is alkaline and can therefore be used in calcareous formations in addition to sands and gravels etc.

RegenOx-enhanced Contaminant Desorption

RegenOx has been designed as a bespoke remediation product to provide advantages in usage and application over commodity chemical products used for ISCO (e.g. permanganates, persulphates, peroxides). One of the design features it includes is reduced losses onto the aquifer matrix, commonly known as the matrix Natural Oxidant Demand (NOD). This is achieved by RegenOx through a powerful desorption / surfactant effect of the combined product (principally the catalyst) that draws the contaminant off the soil surface and into solution / onto the catalytic surface where localised free-radical generation occurs leading to focused contaminant destruction. This restricts the oxidant losses onto tightly bound and heavier soil organics such as humics, roots, and other natural or immobile fractions. At the same time, RegenOx is purely inorganic therefore adding no organic surfactant to the system that may prevent a competitive oxygen sink to on-going contaminant biodegradation.

The present project makes use of this product feature to combine in situ chemical oxidation with enhanced physical mass recovery. RegenOx-desorbed contaminant mass and partially oxidised (more soluble) organic species are recovered via groundwater abstraction using the DPVE system, whilst further contamination is destroyed in situ by oxidation.

Results

Upon completing the RegenOx applications, desorption from the highly impacted soils produced a temporary increase in groundwater hydrocarbon concentrations to a maximum of 4,800 mg/L. One week after the second application was completed, the DPVE system was re-started, rapidly reducing the TPH concentrations in the groundwater to an average of 20 mg/L. The improved efficacy of the DPVE system can be seen in Graph 1 where the linear trendline of MW-2 before and after the RegenOx applications shows a conservative 80% reduction in contaminant concentrations within two months – effectively increasing the DPVE efficiency by more than 500% at this stage in its operation. Once the DPVE system was switched off, further monitoring showed that there was no rebound in groundwater hydrocarbon concentrations due to the augmentation process successfully reducing the sorbed TPH concentrations of the soils.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español