Remediation of a Former Builder’s Yard, Bedfordshire, UK

Case study on the cost-effective treatment of TPH and PAH at a brownfield site in the UK. Read More

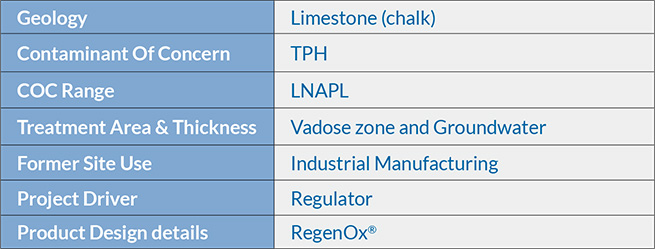

LNAPL Remediation in a Chalk Aquifer under a Residential Property

with BRD Environmental Ltd

Introduction

After completion of the redevelopment of former industrial land into residential properties, significant Total Petroleum Hydrocarbon (TPH) contamination was discovered in the groundwater and smear zone under the gardens and parking area. The TPH comprised diesel and heating oil, with up to 40mm of Light Non- Aqueous Phase Liquid (LNAPL) evident in the monitoring wells.

The original source of contamination (an above-ground storage tank) was removed during redevelopment; however, residual contamination had migrated into a lower chalk aquifer and after the discovery of LNAPL present within chalk fissures above the water table, remedial action was required.

Figure. 1 On site RegenOx® injections using a direct push injection rig

Figure. 2 Total TPH Concentration in Boreholes BH13 and BH14

Method

The two most highly contaminated boreholes, BH13 and BH14, were located in a back garden and a car parking space. As space was restricted and to minimise the impact of works on residents, an in situ remedial technique was deemed the only viable option.

RegenOx® is an In Situ Chemical Oxidation (ISCO) reagent capable of treating high concentrations of a broad range of soil and groundwater contaminants including both petroleum hydrocarbons and chlorinated solvents.

The alkaline nature of RegenOx enabled its use within the chalk aquifer without adverse matrix reaction.

The ability of RegenOx to deal with both LNAPL and dissolved phase contamination avoided the use of ‘pump and treat’ equipment onsite. This minimised both operational and disposal costs and negated the requirement for bulky equipment on the site. Applications were completed using a small direct- push injection rig (Figure 1). This meant that the resident’s parking area could be reinstated at the end of each working day, so that they could park overnight as usual.

The RegenOx injections were completed in three events at two week intervals during June and July.

Results

A 99% reduction of TPH concentrations occurred rapidly in boreholes BH13 and BH14 following the injection works, with LNAPL no longer observed on the site.

Conclusion

A short campaign of RegenOx applications at the site completely removed any LNAPL and reduced TPH concentrations by 99% in a chalk aquifer and regulatory closure was achieved within a short period.

At £55,000 for the product and application work, the project was extremely cost effective, avoiding the use of operational and disposal costs on the site. The in situ nature of the works avoided disturbing or inconveniencing residents living on the site.

Remediation of PHCs and VOCs at a Former Dry Cleaner Site Using RegenOx®, ORC Advanced®, and ORC® Filter Socks

Former Dry Cleaning Site Redeveloped to Serve as New Home to Non-Profit Serving Homeless in Chilliwack B.C. Area

Project Highlights

- Introduction of RegenOx® and ORC Advanced® following in situ treatment using PulseOx1 resulted in the reduction in the initial concentrations of PHCs and dry cleaning chemicals in a sand and gravel aquifer, meeting site remediation goals

- Upon completion of remedial efforts, the project was awarded three British Columbia Ministry Environment instruments

Project Summary

A building occupied by a former dry cleaning business (1960s) located in Chilliwack, British Columbia was acquired by Ruth & Naomi’s Mission, (www.ranmission.ca) a non-profit organization serving Chilliwack. Environmental investigations to support the redevelopment of the former dry cleaner building revealed contamination of the soil and groundwater beneath the site and the offsite alley with petroleum hydrocarbons (PHCs) and dry cleaning related chemicals. Since the remedial excavation onto the offsite alley was not considered to be practical, RegenOx, along with ORC Advanced, was utilized for the in situ treatment of soil and groundwater within the excavation to reduce the remaining PHC and dry cleaning chemical concentrations.

Following treatment with RegenOx, reduction in the concentrations of PHC and dry cleaning related compounds were observed in soil and groundwater samples. RegenOx was additionally injected within the alley to treat the offsite plume. As a result, all post-remediation concentrations are below the applicable commercial land use standards. Additionally, ORC socks were applied to assist natural attenuation of any residual contaminants in groundwater. The successful investigation and remedial effort received three British Columbia Ministry of Environment instruments and now safely serves as a resource center and shelter.

Concentrations

- Volatile Petroleum Hydrocarbons VPH (up to 3,400mg/kg)

- EPH10-19 (8,200 mg/kg)

- Ethylbenzene (33mg/kg)

- Total Xylenes (160 mg/kg)

- Perchloroethylene (7μg/g)

- Trichloroethylene (2.8 mg/kg)

- VPHw (110mg/L)

- LEPH (5.6 mg/L)

- Ethylbenzene (2.14 mg/L)

- Toluene (2.7mg/L)

- Naphthalene (410μg/L)

- Perchloroethylene (2.76 mg/L)

- Xylenes (6.78mg/L)

- Vinyl Chloride (349 μg/L)

Technology Description

RegenOx is a percarbonate-based in situ chemical oxidation technology that rapidly destroys petroleum hydrocarbons and chlorinated contaminants through powerful chemical reactions. It directly oxidizes contaminants while a catalytic component generates oxidizing free radicals to destroy the target compounds.

ORC Advanced is a proprietary formulation of food-grade, calcium oxy-hydroxide that produces a controlled release of molecular oxygen to enhance aerobic biodegredation.

ORC Filter Sock is a permeable filter sock containing calcium oxy-hydroxide based chemical which produces a controlled release of molecular oxygen (17% by weight) when hydrated.

Results

PHC and dry cleaning compounds were reduced in concentrations to groundwater standards following the application of RegenOx and ORC Advanced, facilitating the redevelopment of the former dry cleaning business to house the not-for-profit homeless shelter, Ruth and Naomi’s Mission, serving the Chilliwack, B.C. community. Upon completion of investigation and remedial efforts, the project was awarded three British Columbia Ministry Environment instruments. Up to 200+ homeless are served dinner daily by this organization which provides both shelter and recovery programs to men and women, assisting them in their reintegration into the community and work place.

1 PulseOx is a registered trademark of APT Water, Inc.

ISCO and Enhanced Aerobic Bioremediation during Residential Development

Excavation works minimised through the use of RegenOx, ORC-Advanced and ORC-Advanced Pellets, allowing development to continue without interruption.Read More

RegenOx® Technology Expedites Hollywood Brownfield Site Transaction

Project Highlights

- Reduction of TCE, naphthalene, and styrene levels to below risk-based closure levels via in situ chemical oxidation clears the way for property sale

- Flexibility of RegenOx® application allowed the remediation to be completed faster and more effectively

- Treatment of over 18,000 cubic yards of vadose soil completed within 30 days

Project Summary

A pending real estate transaction of a industrial property in Hollywood, CA was held up by contamination of the vadose zone with a mixture of chlorinated and petroleum solvents. Before the transaction could be finalized, high levels of perchloroethene (PCE), naphthalene, and styrene in the vadose zone soil had to be reduced to below risk-based closure levels. To achieve this, the engineering firm in charge of remediation selected chemical oxidation using RegenOx based on the product’s proven effectiveness, low-cost, and handling safety.

Direct-Push Injection

A remediation plan was developed for the contaminated site that involved two rounds of direct-push application of RegenOx separated by 4 to 6 weeks. The direct-push methodology uses specialized equipment to apply RegenOx to discrete areas of the subsurface without soil removal (i.e., in situ). In order to determine the effectiveness of the treatment, composite soil samples from various grid cells were taken before and after application of RegenOx. Before treatment, significant variation was seen in the contaminant concentrations, with maximum concentrations of 140 μg/kg for PCE, 1200 μg/kg for naphthalene, and 400 μg/kg for styrene. Following the first direct-push application of RegenOx, the average PCE concentration was reduced to 4 μg/kg, a decrease of 86%. Similar results were seen for the petroleum solvents and other chlorinated volatile organic compounds (cVOCs) in the composite soil samples.

Soil Mixing Applicationhollywood2

Despite the contaminant reductions achieved by the first direct-push application of RegenOx, REGENESIS® Remediation Services determined that the speed and effectiveness of the remediation effort could be significantly improved by switching to soil mixing application of RegenOx. In this more aggressive approach, RegenOx was mechanically blended into the vadose soil in order to maximize the contact between the product and the contaminated soil. RegenOx was added as an eight percent solution and mixed throughout the soil using soil mixing equipment. With this treatment method, approximately twice as much soil was treated per day compared to direct-push application.

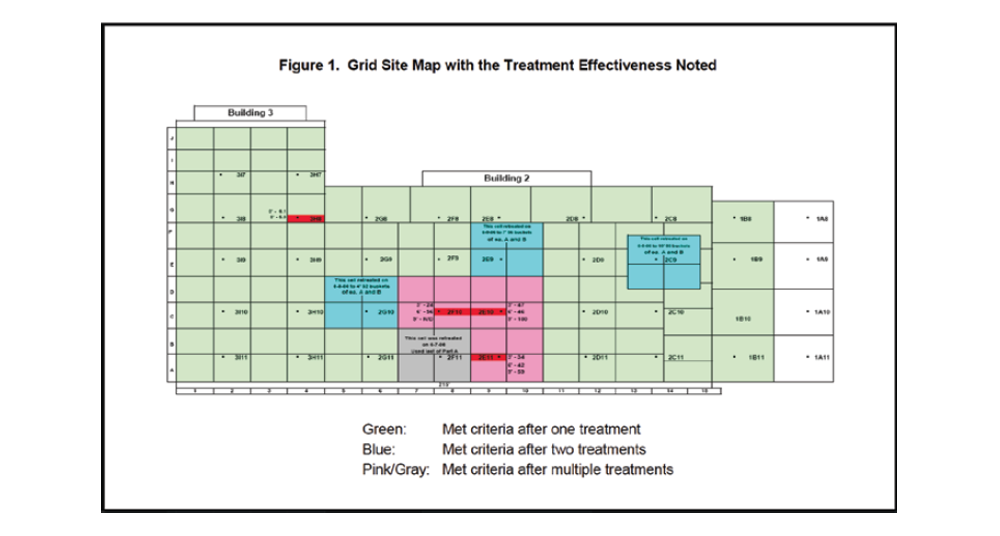

Of the 111 grids treated with RegenOx by soil mixing (Figure 1), 83 required only one treatment (green) to achieve levels below risk-based closure, 12 required two treatments (blue), and 16 required more than two treatments (pink and gray).

Technology Description

RegenOx is a percarbonate-based in situ chemical oxidation technology that rapidly destroys petroleum hydrocarbons and chlorinated contaminants through powerful chemical reactions. It directly oxidizes contaminants while a catalytic component generates oxidizing free radicals to destroy the target compounds.

Results

The mixed chlorinated and petroleum solvent contamination of the vadose soil was effectively reduced using RegenOx in both direct-push and soil mixing applications. Soil mixing was used to complete the remediation effort rather than a second round of direct-push injections because it maximized contact between RegenOx and the contaminated soil, achieving more rapid and effective treatment. In 74% of the treatment grids, concentrations of all the contaminants were reduced below the risk-based cleanup goal with a single application by soil mixing. Additional applications in the remaining 26% of the treatment grids also achieved the targeted levels for all the contaminants. This remediation approach successfully treated nearly 18,000 cubic yards of soil within 30 days. Using RegenOx and flexible application methods, the site was quickly and effectively remediated, allowing for the real estate transaction to be completed.

RegenOx® and ORC Advanced® Application Reduces BTEX , MTBE, and TBA Concentrations to Below MCL

Site closure granted.Read More

Military Fuel Depot Remediation in Moheda, Sweden

Integrated treatment of a x-large scale petroleum hydrocarbon plume contaminationRead More

Combined Remediation Approach Allows for Redevelopment, UK

Integrated treatment with In Situ Chemical Oxidation (RegenOx) and Dual Phase Vacuum ExtractionRead More

Environmental Remediation Beneath Residential Properties, UK

In order to treat the high contaminant concentrations, an integrated method was chosen. High levels of TPH were chemically oxidised using RegenOx. The residual dissolved phase contamination was treated using ORC Advanced.Read More

In Situ Remediation of an Operational Petrol Filling Station in Northern Italy

In Situ chemical oxidation and bioremediation treat TPH and BTEX. Regulatory acceptance despite low permeability aquifer.Read More

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español