Performance-Based Objectives Achieved at Scott AFB

Case study highlights:

- Impacted soil was caused by leaking underground piping and removal of two large UST’s

- Second round of direct push injections included PetroFix to treat lingering BTEX

- One month following application of PetroFix, BTEX levels were at non-detect and have continued to remain at that level for 5 sampling events

This case study reviews the Corrective Action Plan (CAP) at Scott Air Force Base, a large military base located in Southwestern Illinois that was contaminated with petroleum impacted soil. One month following the application of PetroFix™, contaminant levels reached non-detect. Benzene continued to remain non-detect through March 2020 and the site was recommended for no further action. The final CAP Addendum proposed two rounds of groundwater treatment by injection at Former Tank 85 to reduce benzene concentrations below the groundwater remediation objectives. The first round of injections was completed in February through March 2018 and consisted of the use of REGENESIS’ RegenOx®, coupled with ORC Advanced® to stimulate aerobic bioremediation. The initial injection was successful in reducing most contaminants within the affected area. The second round of injections at the former UST was completed in March 2019 using REGENESIS’ PetroFix micron-scale remedial fluid.

Cost-Effective Treatment To Address PCE At Former Dry Cleaning Site

Case study highlights:

- Soil mixing with PersulfOx® cost less than half of the thermal desorption treatment.

- Very aggressive remediation goals were met on a quick timeline.

- One application of PersulfOx was powerful enough to reduce contaminant levels from 18,000 ppm to 150 ppm.

This case study reviews a former dry cleaning site in an upscale Chicago suburb that was contaminated with chlorinated solvents, specifically perchloroethylene. Cabeno Environmental, a turnkey environmental contractor, worked alongside REGENESIS to create an effective remedial design for this high profile site. They chose to treat the contaminated soil with in situ soil mixing using PersulfOx, an activated persulfate. Cabeno Environmental chose to treat the contaminated soil with in situ soil mixing using PersulfOx, an activated persulfate. This technology was chosen because it effectively and rapidly promotes in situ oxidation of a wide range of organic contaminants. After Cabeno Environental conducted a pilot test to refine the remedial design, the site was treated with hydrogen peroxide and 83,146 pounds of PersulfOx. Within one month of completing the soil mixing, the closure sampling was conducted. This quick timeline along with strict remediation goals demonstrated the power and effectiveness of the PersulfOx technology.

Single Application of ORC Advanced® Results in 87% Reduction of Contaminated Groundwater Plume

Project Highlights

- Size of contaminated groundwater plume reduced by 87% through extensive injection of ORC Advanced, applied using vertical and horizontal wells.

- Total BTEX >62.5ppm (mg/l) concentrations were identified prior to site treatment.

- Final round of ORC injections approved by Illinois EPA and LUST Program and is in-progress.

Project Summary

This site had been a carwash and retail gasoline station in an industrial-commercial area. During the removal of two (2) 6,000- gallon gasoline underground storage tanks (UST) and two (2) fuel dispensers, a gasoline release was reported to the Illinois Management Emergency Agency, based on impacted soil observed during the excavation. Contaminants for this gasoline release were Benzene, Toluene, Ethylbenzene, and total Xylenes (BTEX). The release resulted in groundwater contamination that encompassed the entire property, and extended slightly off-site, impacting three businesses. The area covered by the groundwater plume was approximately 1.5 acres. The size of the groundwater BTEX plume posed a significant challenge in site treatment.

Remediation Approach

In this instance, LandTech, Inc. implemented an Enhanced Aerobic Biodegradation strategy using ORC Advanced. This included 12,800 pounds of ORC Advanced, 7 pounds of Nitrate, and 1 pound of Phosphorous nutrients applied to the site via direct injection through 242 vertical wells to 16 feet below ground surface, and 1,065 feet of horizontal wells beneath the existing structures. ORC Advanced® is an engineered, oxygen release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils. ORC Advanced provides remediation practitioners with a significantly faster and highly effective means of treating petroleum contaminated sites.

Results

This site presented significant challenges due to the extensive levels of BTEX contaminants and the large area of groundwater contamination. After one round of injections and a monitoring period of 1 year, analytical results for the groundwater demonstrated the ORC injections have reduced the 1.5 acre BTEX groundwater plume by 87%. A second/final round, 1,350 pounds, of ORC Advanced injections have been approved by the Illinois EPA to address a few recalcitrant performance wells.

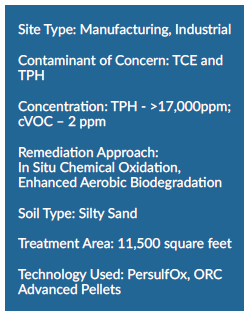

ISCO Treats High Levels of TCE with Planned Enhanced Bio for TPH Treatment

157,000 lbs. of PersulfOx® Applied to Treat Illinois Manufacturing Facility

Project Highlights

- Remediation mandated after oil sheen observed in river adjacent to manufacturing facility

- In Situ chemical oxidation (ISCO) paired with excavation to remediate site

- Tight treatment deadline met through supply of 51 PersulfOx SuperSacks, containing 2,204 lbs. each, which were delivered within a few days’ notice

- TPH soil plume has been reduced by >90% (from 6,111 cubic yards to 555 cubic yards)

Project Summary

An operating metal fabrication facility, located in Illinois, caused subsurface impacts from the use of cutting oils and degreasing solvents. This resulted in high levels of TPH and TCE in soil and groundwater. The state of Illinois cited the facility for a violation when an oil sheen was observed seeping from the property into an adjacent river. A mechanical oil recovery system was installed and absorbent booms were used to stop oil from reaching the river. ISCO was selected as the remediation approach to treat the contamination below the active facility. The TCE area was treated with PersulfOx via injection wells and a soil mixing application with an excavator.

Remediation Approach

Prior to the start of remediation activities, a change in the primary consultant was made and a new consultant was brought in. The new consultant imposed a tight deadline of several months to complete the full scope of remediation activities. REGENESIS was able to assist with keeping the project on-deadline through the timely delivery of 51 PersulfOx SuperSacks, containing 2,204 lbs. each. The PersulfOx SuperSacks were delivered within a few days’ notice. The consultant installed a series of injection wells within and outside of the building. PersulfOx was injected into these wells during three applications over a three-month period. Additionally, the TCE area was treated with PersulfOx® through a soil mixing application using an excavator. The final step of the remediation plan is to treat the TPH-impacted soils outside the building through excavation and the application of Oxygen Release Compound (ORC®) Advanced Pellets which will supply a long-term oxygen source of oxygen for enhanced bioremediation of the residual TPH. The client is also evaluating the use of PlumeStop to change the FOC value of the soil for a site specific Tier 3 closure level via MNA for an area that had extremely high TPH values >40,000ppm.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced Pellets are a pelletized version of REGENESIS’ widely used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications.

Combined Remedies Approach Reduces CVOCs up to 97% in 78 Days

Project Highlights

- Downtown Chicago site planned for multi-million dollar redevelopment

- Manufacturing operations caused CVOC impacts in groundwater of up to 6500 ug/L

- Redevelopment schedule required effective treatment with timely implementation

- Monitoring wells indicated up to 97% reduction of CVOCs 78 days post treatment

Project Summary

This site in downtown Chicago, was impacted by chlorinated solvents used in various historic manufacturing activities. DCE and TCE concentrations were recorded up to 7,440 µg/L in a sand formation over clay. As the site was to be redevelopment as a hotel and sports arena, and any programme delays would be extremely costly, the client needed a quick and permanent remedy to achieve the stringent target levels (of: total VOC MCL 567 µg/L and TCE MCL 242 µg/L) REGENESIS successfully remediated the groundwater to below target levels within the tight time window.

Treatment

The designed volumes of PlumeStop, HRC, and BDI Plus were successfully applied within the defined treatment zones (see map right) during the application event. A combined volume of 265 m3 of PlumeStop, HRC and BDI Plus was injected via 138 direct push injection points.

Results

78 days post-application, the two key validation wells (AW 3-3 and AW 3-2) observed 80% and 97% reduction in total CVOCs. BDI Plus was used to facilitate the bioaugmentation. As a result, the DHC sp. count and functional genes of the anaerobic metabolic pathways increased significantly from baseline measurements, as determined by QuantArray® analysis. This means that not only contaminant sorption is occurring, but that biodegradation is happening as well. The second and third monitoring round (at 108 and 138 days) confirm the production of breakdown products, indicating that enhanced reductive dechlorination (ERD) is ongoing. Regulatory sign-off is applied for.

What’s Special?

- Unsupported by PlumeStop, bioremediation would not have been an option for a site with such a tight programme. This project shows that accelerated bioremediation using Plumestop can compete with In Situ Chemical Oxidation on time

- The execution of this application was unique because of the tight project programme

- Rapid reduction in groundwater contamination: 80 – 97% from first sampling interval of the total solvents. The concentration levels in all wells are now compliant.

Technology Description

PlumeStop™ Liquid Activated Carbon™ is composed of very fine particles of activated carbon (1-2μm) suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix binding to the aquifer matrix, rapidly removing contaminants from groundwater, and expediting permanent contaminant biodegradation.

HRC® is a controlled release, electron donor material, that when hydrated is specifically designed to produce a controlled release of lactic acid. The newly available lactic acid is critical for the production of hydrogen to fuel anaerobic biodegradation processes in soil and groundwater.

Bio-Dechlor INOCULUM® Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Regenesis Remediation Services™ – PCE Plume Treated with RegenOx®

In Situ Chemical Oxidation Reduces Contamination Concentrations at a Former Dry Cleaner Site

Regenesis Remediation Services (RRS) was contracted to design and perform in situ chemical oxidation (ISCO) via soil mixing to remediate tetrachloroethylene (PCE) impacted soil at a former dry cleaner site located in Cook County, Illinois. RegenOx® was chosen as the primary remediation technology for the chemical oxidation. The treatment area focused on soilbound PCE contamination around 1,170 mg/kg in the clay-rich unsaturated soils. The soil remediation objective was to reduce PCE levels below the 240 mg/kg soil saturation limit established by the Illinois EPA.

The impacted soils were removed by a mini trackhoe excavator and placed inside a vacant unit adjacent to a treatment cell where the soil mixing was performed. A proportional amount of RegenOx was evenly dispersed throughout the excavated, contaminated soil, then thoroughly mixed using the excavator. Once mixing was complete, the soils were placed back into

the treatment cell while being hydrated with a RegenOx solution.

By optimizing the contact between the soil, contaminants, and RegenOx, powerful desorption effects strip PCE off of the soil matrix and onto the RegenOx catalytic surface. This catalytic surface contributes to localized free-radical generation, leading to focused and efficient contaminant destruction. Approximately 242 cubic yards of soil bound contaminant mass was successfully treated at this site. Soil mixing was performed from surface grade to approximately 10 feet below grade.

In Situ Chemical Oxidation Treats High TPH Concentrations

Over 114,000 Pounds of PersulfOx® Applied to Illinois Manufacturing Facility

Project Highlights

- High levels of TPH and TCE were detected on-site after a suspected cutting oil/degreasing solvent spill.

- Remediation mandated after oil sheen observed in river adjacent to manufacturing facility.

- In Situ chemical oxidation (ISCO) paired with excavation to remediate site.

- Tight treatment deadline met through the use of PersulfOx in 2,204-pound SuperSacks, which were delivered within a few days’ notice.

Project Summary

An Illinois metal fabrication manufacturing facility has been in operation since the early 1900s and is still active today. The use of cutting oils and degreasing solvents lead to high levels of TPH and TCE on-site. The state of Illinois cited the facility for a violation when an oil sheen was observed seeping from the property into an adjacent waterbody. A mechanical oil recovery system was installed and absorbent booms were used to mitigate the oil from reaching the river. ISCO was selected as the remediation approach to address the contamination below the active facility through a series of applications. Additionally, the TCE area was treated with PersulfOx® via injection wells and a soil mixing application.

Remediation Approach

Prior to the start of remediation activities, the primary consultant was removed from the project and a new firm was brought in. The remediation firm placed a tight deadline (a couple of months) to complete the full scope of activities. REGENESIS was able to assist with keeping the project on-deadline through the delivery of 2,204-pound PersulfOx SuperSacks, which were delivered within a few days’ notice. The consultant had a series of injection wells installed inside and outside of the building. PersulfOx was injected into these wells during three applications over a three-month period. Additionally, the TCE area was treated with PersulfOx through a soil mixing application using an excavator. The final step of the remediation plan is to treat the TPH-impacted soils outside the building through excavation, and Oxygen Release Compound (ORC®) Advanced Pellets will be used as a long-term oxygen source for enhanced bioremediation of the residual TPH.

Technology Description

PersulfOx is a sodium persulfate-based chemical oxidation technology which destroys both hydrocarbon and chlorinated solvent-type contaminants in the subsurface. PersulfOx contains a built-in catalyst which activates the persulfate component and generates contaminant-destroying free radicals without the need for the addition of a separate activator.

ORC Advanced Pellets are a pelletized version of REGENESIS’ widely used ORC Advanced and are designed specifically for direct application into excavations, tank pits and trenches. This pelletized, dry application material minimizes airborne dust while eliminating the need for specialized equipment and spray water required for powder-slurry applications.

Combined Remedies Used at Historic Illinois Chemical Company

cVOCs in Bedrock Treated at Active Manufacturing Facility

Project Highlights

- Regenesis Remediation Services (RRS) used combined technologies to work toward the shutdown of a pump and treat (P&T) system.

- Previous Enhanced Reductive Dechlorination (ERD) technology applications did not achieve COC reductions.

- Advanced ERD, Bioaugmentation and ISCR remedies were combined and applied into weathered bedrock.

- The project required RRS to be PICS certified. PICS is a contractor prequalification services used many large E&C and fortune 500 companies.

Project Summary

The site is home to an active chemical manufacturing facility with historic spills of cVOCs. Within the contamination impact zones, a groundwater P&T system is being used to mitigate off-site migration of cVOCs in the groundwater. The consultant was seeking ways to turn off the P&T system by treating the plume in-situ. They had previously used an ERD technology without fully achieving primary COC reductions. RRS designed and implemented a pilot study for the site.

Remediation Approach

The pilot study was designed to test Regenesis’ combined remedy approach which incorporated ERD using 3-D Microemulsion, Bioaugmentation with BDI Plus and ISCR with CRS. RRS applied the integrated technologies through direct-push borings. The 2,500-square-foot treatment zone included 10-foot vertical injections into silty sand and clay over weathered dolomite bedrock.

Technology Description

- 3-D Microemulsion is an engineered electron donor material that offers a novel 3-stage electron donor release profile, pH neutral chemistry and is delivered on-site as a factory–emulsified product.

- HRC Primer is a less viscous version of the standard Hydrogen Release Compound (HRC) product. It is a thinner, water-like compound that is typically injected into an aquifer where it releases lactic acid at a rate faster than standard HRC (several weeks), but at a slower, more controlled rate than dispersing aqueous simple sugar solutions or straight lactic acid (several days).

- Bio-Dechlor INOCULUM Plus is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

- CRS® (Chemical Reducing Solution) is an iron-based amendment for in situ chemical reduction (ISCR) of halogenated hydrocarbon contaminants such as chlorinated ethenes and ethanes.

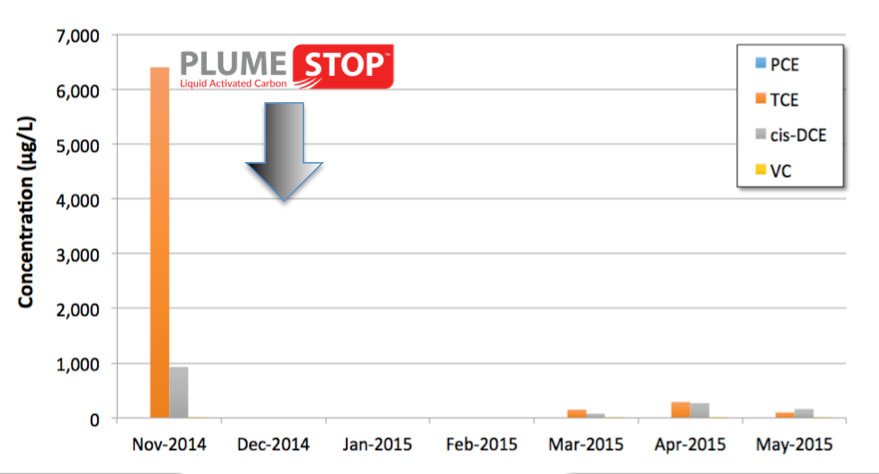

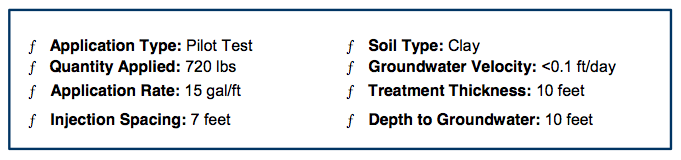

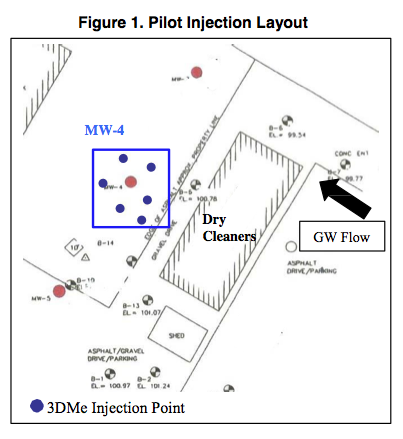

3-D Microemulsion® Enhances Reductive Dechlorination and Reduces PCE and TCE Concentrations to Non-Detect

CASE SUMMARY

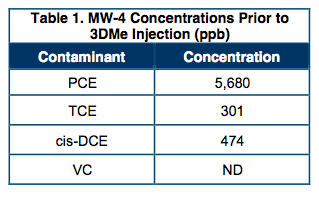

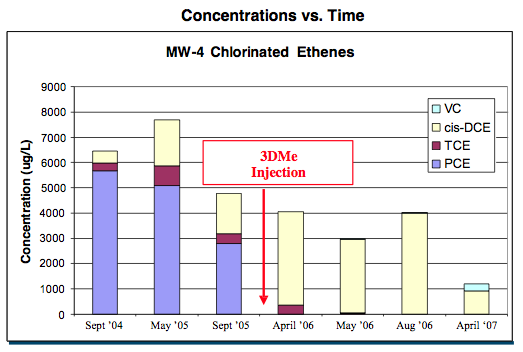

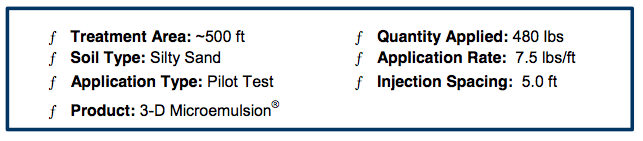

Operations at a dry cleaning facility in Illinois resulted in elevated levels of chlorinated ethenes in the subsurface. Downgradient of the contaminant source (in Well MW-4), the total chlorinated compound concentration was greater than 6,400 parts per billion (ppb), the main contaminant being tetrachloroethene (PCE). A pilot test using Hydrogen Release Compound (HRC®) was initially designed and deployed to produce conditions favorable for the reduction of contaminants. Well MW-4 was the designated sampling point to observe the contaminant reduction. The HRC pilot application was mis-applied over a 20 foot vertical interval instead of the recommended and planned 10 foot interval, resulting in under-dosing of HRC and only moderate treatment performance. A second application was performed 18 months later using the correct dosing of 3-D Microemulsion (3DMe)®.

REMEDIATION APPROACH

3-DMicroemulsion is a completely new molecule with staged hydrogen release capabilities and is applied as a microemulsion for enhanced distribution. The 3-D Microemulsion was directly injected at 6 locations surrounding the targeted monitoring well MW-4 (Figure 1). It was injected at a rate of 120 pounds per injection point and at 10 to 20 feet below ground surface (at the correct 10 foot interval). The injection points were spaced approximately 7 feet from one another.

RESULTS

Although HRC was applied and under-dosed in September 2004, moderate increases in the reductive dechlorination process were observed near Well MW-4. The moderate effect resulted in a 50 percent decrease in PCE concentrations. As expected some daughter products were also produced.

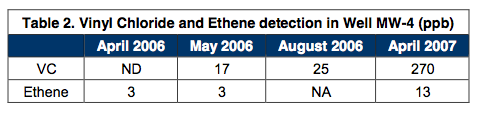

Within 30 days of the 3DMe application, PCE was reduced from 5,680 ppb to non-detect followed by a similar reduction in TCE. A reduction of 77 percent was observed in cis-DCE between August 2006 and April 2007. Slight increases in vinyl chloride (VC) and ethene indicated that complete dechlorination was occurring with no stalling effect (Table 2).

CONCLUSION

Biostimulation using 3-D Microemulsion was successful in treating the target contaminants as a result of the proper dosing/emplacement of the material and overall product performance. In MW-4, PCE and TCE were reduced to non-detect while total chlorinated compounds were reduced by more than 70 percent.

3-D Microemulsion® Bio-Barrier Rapidly Treats Cis-DCE and Vinyl Chloride Contamination and Maintains Reductive Dechlorination Over a 1,200-Day Period

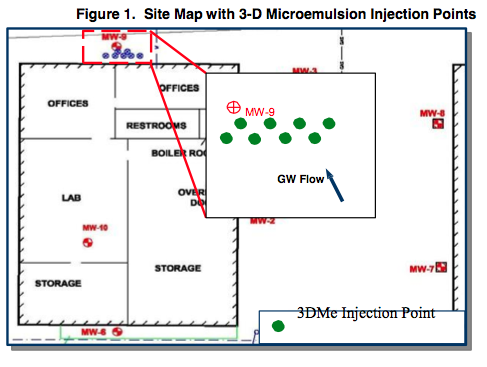

CASE SUMMARY

Cis-1,2-dichloroethene (cis-DCE) and vinyl chloride (VC) were migrating off-site at this commercial facility. A pilot test of enhanced anaerobic bioremediation was performed to determine if a bio-barrier using 3-D Microemulsion, a form of HRC Advanced®, could effectively reduce the cis-DCE and VC contamination before it moved off-site. The remediation design included the subsurface injection of 3-D Microemulsion upgradient of contaminated well MW-9.

TECHNOLOGY DESCRIPTION

Reductive dechlorination is a process used to degrade certain contaminants in groundwater (e.g., cis-DCE and VC) to ethene. 3-D Microemulsion is a highly effective agent to facilitate this process. 3-D Microemulsion is composed of free lactic acid, controlled-release lactic acid (polylactate), and certain fatty acid components esterified to a carbon backbone molecule of glycerin. When injected into contaminated soil and groundwater, 3DMe produces a sequential, staged release of its electron donor components. The immediately available free lactic acid is fermented rapidly while the controlled-release lactic acid is metabolized at a more gradual rate. The fatty acids are converted to hydrogen over a mid- to long-range timeline giving 3DMe an exceptionally long electron donor release profile. This staged fermentation provides an immediate, mid-term, and very long-term controlled release supply of hydrogen (electron donor) to fuel the reductive dechlorination process.

REMEDIATION APPROACH

The objective at the site was to demonstrate the ability of 3-D Microemulsion to prevent the off-site migration of cis-DCE and VC by contaminant reduction. The reduction was to be achieved by the introduction of 3DMe into the subsurface through 8 injection points spaced 5 feet apart (Figure 1).

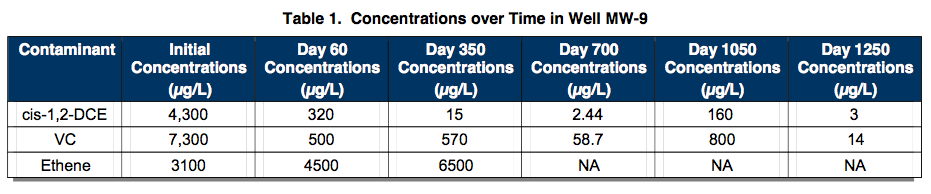

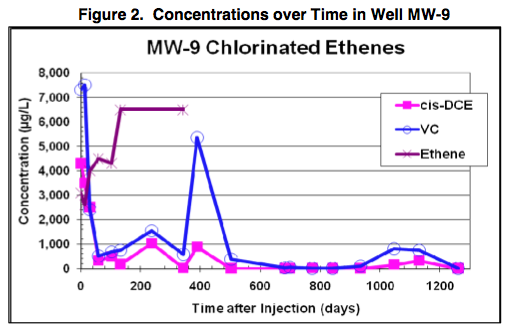

RESULTS

Within 60 days of the application of 3-D Microemulsion, concentrations of the target contaminants were significantly reduced (Table 1 and Figure 2). Over the 1,200-day monitoring period, cis-DCE was reduced by a magnitude of 3 from 4,300 to 3 micrograms per liter (μg/L). VC was reduced by 2 orders of magnitude from 7,300 to 24 μg/L, interrupted briefly by an anomalous spike likely to be laboratory error. As a result of this process, ethene concentrations increased by 102 percent, from 3,100 to 6,500 μg/L, after 130 days (a clear indication of complete dechlorination). Elevated levels of ethene were maintained for more than 300 days until ethene monitoring ended at Day 350 (Figure 2)

CONCLUSION

Overall, the results of this pilot test clearly show that when using 3-D Microemulsion, chlorinated ethene degradation via enhanced reductive dechlorination can be achieved both rapidly (60 days after injection) and successfully maintained over the long term.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español