PersulfOx provides safe and rapid treatment of impacted soils

With RGS Nordic

Summary

An area of impacted soils was discovered at an oil-distribution depot at a Swedish harbour. This was thought to have occurred due to historic spillages and leaks from industrial land use on the site. Remediation of the soils was required to MKM levels (Swedens generic industrial land use clean-up criteria).

Download pdfAs the contaminated soil was quite shallow (1.0-2.5m BGL) it was determined that excavation would be easily achieved. Treatment of the soils through biopiling or windrows was not deemed appropriate due to limited space. Therefore ex situ mixing of the soils with a chemical oxidant, PersulfOx, was chosen in order to provide rapid reduction of the contaminant mass. This would be followed by a short period of enhanced biological degradation in the treated soils, stimulated by the increased redox in the soil moisture following the chemical oxidation process. Partial chemical oxidation of the hydrocarbons into more bioavailable and biodegradable compounds would also accelerate biodegradation of a proportion of the residual contaminant mass.

PersulfOx was added into the soils at a dosage rate of 17kg per 1m3 of soils. This was then mixed thoroughly using an Allu hydraulic bucket, during which the soils were wetted. This would increase the soil moisture in order to facilitate the chemical reaction. Care was taken to avoid adding too much water and risk damaging the geotechnical properties of the soils.

The sides and base of the excavations were validated to delineate the vertical and lateral extent of the impacted zone and ensure that all of the contaminated soil had been removed. Following application of the PersulfOx, the treated soils were then placed back into the excavations and validated. Following successful validation, the soils were compacted to the required capacity in order to allow site traffic to pass over the treated areas.

Results

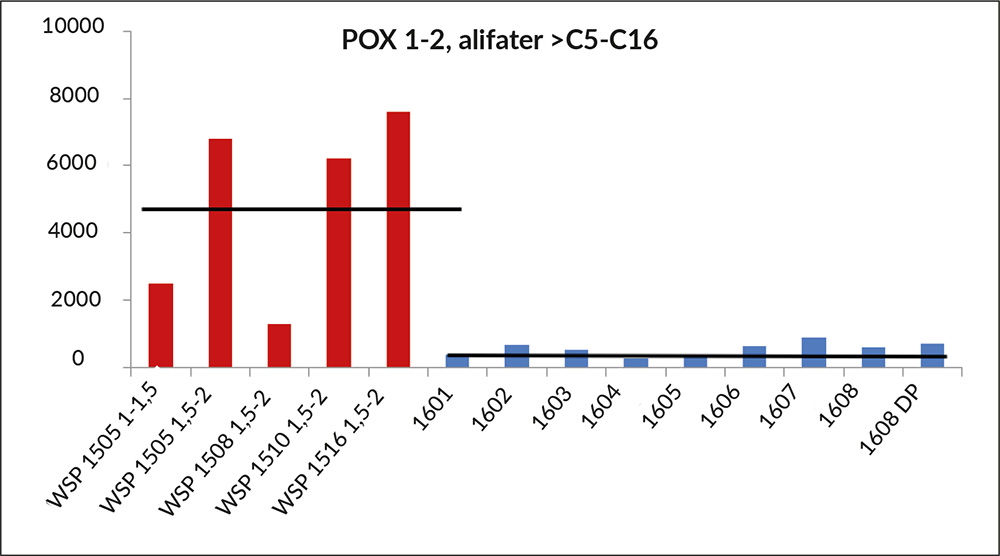

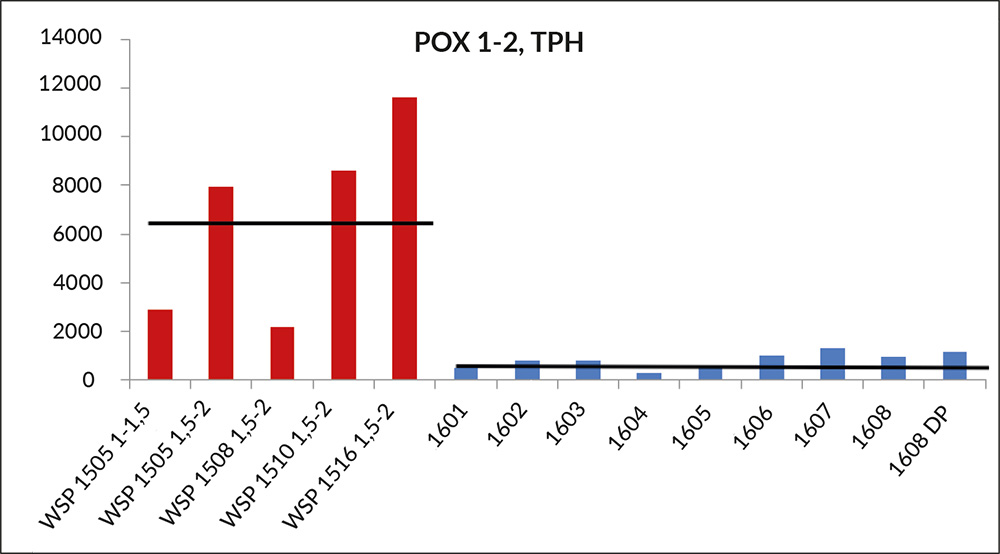

Sampling of the soils three months after treatment, showed that the target concentrations had been reduced to below the target guideline values, see Figure 1 and 2.

Fig. 1: Combined results from both areas, Aliphatic C5-C16

- The impacted soils were successfully remediated in a short period of time.

- Due to its built-in catalyst, the use of PersulfOx avoided the need for dangerous activators such as hydrogen peroxide or caustic soda, making the remediation process much safer.

- The treatment area was minimised, making the remediation of the soils practical and avoiding greater disruption to the site operator.

Fig. 2: Combined results from both areas, Total Petroleum Hydrocarbons

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español