December 2020 Newsletter

Client Spotlight: Arun Wahi

Arun Wahi, Senior Hydrogeologist with INTERA Inc., a leading international geosciences and engineering consulting firm, specializes in contaminant fate and transport analyses of organic and inorganic contaminants and radionuclides, including numerical models of vadose zone and groundwater flow and transport. He shares, “I enjoy the challenges associated with mathematics and learning new chemistry of emerging contaminants or forensic techniques, but the most rewarding part of my job is influencing concrete actions that protect human health and the environment.” Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

Combined Remedy Reduces Chlorinated Solvents to Achieve Closure Status with Florida DEP

This case study reviews the site of a chlorinated solvent spill as part of former dry cleaner operations at a retail shopping center in St. Petersburg, Florida. AECOM®, a global environmental consulting firm, was engaged to develop a solution for the site. The application called for an in situ groundwater treatment of low-concentration chlorinated volatile organic compounds (CVOCs). AECOM enlisted REGENESIS to design and implement an innovative sorption-enhanced reductive dechlorination (ERD) bioremediation approach for treating the CVOC contaminants. The results of the effort led to the Florida Department of Environmental Protection issuing a Site Rehabilitation Completion Order, releasing the property owner from further obligation to conduct remediation at the project site (i.e., site regulatory closure).

Turn Polluted Aquifers into Purifying Filters with PlumeStop

Low-cost Bioremediation of Chlorinated Solvents

HRC is an engineered, hydrogen release compound designed specifically for enhanced, in situ anaerobic bioremediation of chlorinated compounds in groundwater or highly saturated soils. HRC enables enhanced anaerobic biodegradation by adding hydrogen (an electron donor) to groundwater and/or soil to increase the number and vitality of indigenous microorganisms able to perform the naturally occurring process of enhanced reductive dechlorination. Due to its capability of being applied via permanent wells, direct-push, and excavations, this reagent allows for clean, low-cost, non-disruptive application.

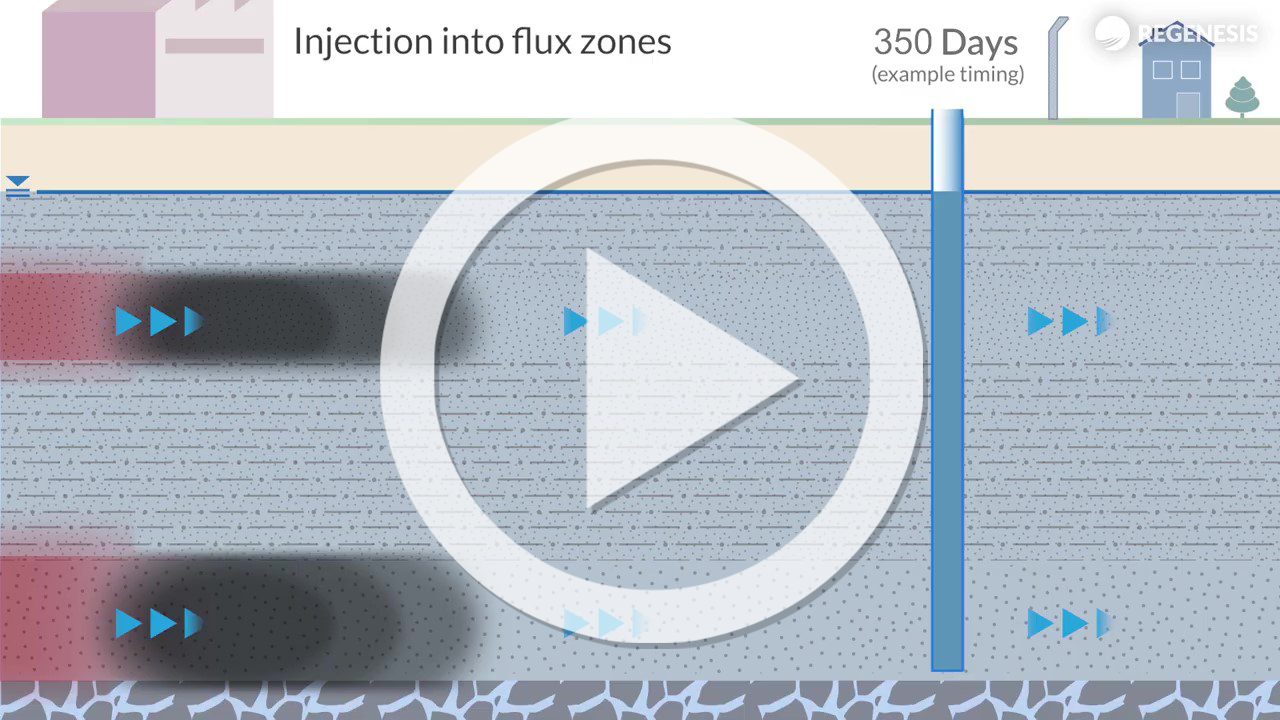

Remediation of Chlorinated Solvents with PlumeStop Liquid Activated Carbon

PlumeStop technology can be applied to inhibit spreading of contaminant plumes, to protect sensitive receptors, or to prevent contaminant migration across property boundaries. It is also an effective tool for control and treatment of groundwater contamination associated with low-permeability porous formations and matrix back-diffusion, promoting diffusion out of the immobile porosity while preventing groundwater impact, and for treating sites with very low contaminant concentrations. Once in place, PlumeStop is expected to last for decades with minimal impact on aquifer oxidation-reduction potential, permeability and geochemistry.

Webinar Now Available: A State Regulator’s Perspective on PFAS in Minnesota

In this webinar we were pleased to have as a special guest speaker Ginny Yingling, Senior Hydrogeologist at Minnesota Department of Health. Her presentation shared a state regulator’s perspective on PFAS in Minnesota. She was joined by Scott Wilson, President & CEO at REGENESIS, who discussed the extent to which colloidal activated carbon has been accepted by the remediation industry as a low-cost method of eliminating PFAS risk.

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

November 2020 Newsletter

Client Spotlight: April McGuire

By working with various teams to design and complete projects that help reduce a development’s impact on the environment, and by producing results that exceed client expectations, April McGuire, Project Engineer for Roux receives a “double dose” of satisfaction from her work. She shares, “Working with other intelligent and passionate people in the Roux Long Beach office on complex sites, delivering on projects, and making clients happy is what it’s all about.” In her current role, she manages various types of projects, including remediation, site investigations, and vapor intrusion mitigation system designs.

Subscribe To Our Monthly Newsletters

PlumeStop Effectively Degrades Contaminants to Lead Northern California Site to NFA Status

This case study reviews one of the original PlumeStop® pilot tests for in-situ groundwater treatment of chlorinated volatile organic compounds (CVOCs or chlorinated solvents) at a former dry cleaner location in Marina, California. REGENESIS treated the CVOCs using a novel, sorption-enhanced reductive dechlorination (ERD) approach. This approach consisted of immediate sorption followed by the sequential elimination of chlorine from the CVOC molecules, transforming them into non-toxic end products such as ethene, carbon dioxide, and chloride.

Turn Polluted Aquifers into Purifying Filters with PlumeStop

Webinar Now Available: Matt Burns Showcasing Proven Methods for Saving Time and Money

In this webinar we were pleased to have as a special guest speaker Matt Burns, Technical Director of Environmental Services for WSP. His presentation discussed proven methods for saving time and money using in-situ activated carbon remediation. He was joined by Maureen Dooley, Director of Strategic Projects at REGENESIS

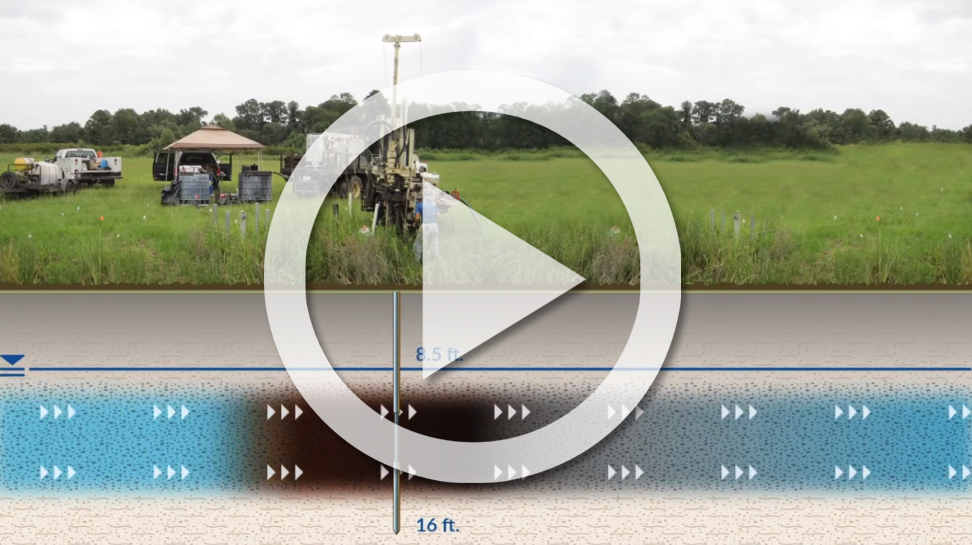

Petroleum Hydrocarbons Treated with PetroFix at Former Naval Auxiliary Air Station, Edenton Site is the 3rd NAAS Site Successfully Treated with PetroFix

This video showcases the former Naval Auxiliary Air Station, Edenton, the third Naval Auxiliary Air Station site successfully treated with PetroFix. In order to quickly close the site, the responsible party has chosen PetroFix to reduce contaminants to below North Carolina groundwater quality standards. The micron-scale liquid carbon amendment was chosen because it was the most cost-effective, easy-to-apply solution to treat the petroleum hydrocarbons in groundwater.

Apply Activated Carbon Under Low Pressure to Treat Petroleum Hydrocarbons

PetroFix is an activated carbon remediation technology that is easily injected in situ under low pressure, distributes in the subsurface without fracturing, and includes electron acceptors to stimulate biodegradation of petroleum contaminants in soil and groundwater. This cost-effective technology is designed to remediate petroleum spills and provide immediate results for gas station and UST sites. It works with the PetroFix Design Assistant™, an online design tool that enables users to individually tailor their site designs and self-apply PetroFix.

Newly Released Webinar Provides Guidance for In-Situ Remediation at Fractured Bedrock Sites

This webinar covers the challenges of the treatment within bedrock aquifers and discusses appropriate resources to help with the design of site investigations for fractured bedrock sites, enabling the deployment of robust in-situ remediation strategies. Jack Shore, UK and Scandinavia District Manager for REGENESIS, explains how a range of technologies can be used to overcome these challenges; focusing on in-situ anaerobic and aerobic biological degradation, sorption using micron-scale colloidal activated carbon, enhanced desorption coupled with vacuum extraction and in-situ chemical oxidation.

Webinar with PFAS Industry Expert, Dr. Grant Carey Presenting on PlumeStop Longevity

In this webinar we were pleased to have as a special guest speaker Grant Carey, Ph.D., President of Porewater Solutions. His presentation discussed PlumeStop longevity for in-situ PFAS plume treatment. He was joined by Ryan Moore, PFAS Program Manager at REGENESIS, who discussed in-situ treatment of PFAS using colloidal activated carbon to eliminate PFAS risk at a low cost.

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

October 2020 Newsletter

Client Spotlight: Joel Parker

For Joel Parker, Principal Engineer with Hamp, Mathews & Associates, a Michigan-based environmental remediation firm, the opportunity to combine his passion for science with practical remediation solutions that impact our everyday lives provides the ideal footing for offering clients sound technical advice that can lead to optimal remediation outcomes. He begins, “My favorite aspect of my position is living at the fringes of all the sciences. I function at a nexus of physics, chemistry, biology, geology and hydrogeology. It is very rewarding to ‘play’ in a space where those sciences mix in the real world.” Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

Colloidal Carbon Barrier Protects Neighborhood from Chlorinated Solvent Plume

This case study reviews a field-scale pilot test using REGENESIS technologies for in situ groundwater treatment of chlorinated volatile organic compounds (CVOCs) at high concentrations, in a fast-moving, aerobic aquifer beneath a residential neighborhood. The CVOCs were treated using a unique combination of remediation technologies, symbiotically promoting sorption-enhanced reductive dechlorination (ERD) via biotic and abiotic processes. Hamp, Mathews & Associates, Inc., a leading environmental consultant, enlisted REGENESIS to design and install an in situ permeable reactive barrier (PRB) to fully treat the tetrachloroethene (PCE), trichloroethene (TCE), cis-1,2-DCE (cis-DCE), and vinyl chloride, converting them into nontoxic end products such as ethene, ethane, carbon dioxide, and chloride.

Turn Polluted Aquifers into Purifying Filters with PlumeStop

ZVI Optimized for Reactivity and Superior Distribution

REGENESIS offers S-MicroZVI, an advanced zero-valent iron (ZVI) product proven to accomplish In Situ Chemical Reduction (ISCR) of contaminants within the subsurface environment. S-MicroZVI is delivered as a colloidal suspension 40% ZVI by weight in glycerol with a particle size of less than 5 microns. S-MicroZVI is manufactured using a state-of-the-art sulfidation process resulting in a particle coating which increases activation toward specific contaminants and extends performance longevity. S-MicroZVI destroys contaminants abiotically and applied to stimulate ISCR-enhanced bioremediation.

PFAS Remains at Non-Detect After 20 Months Following Application of PlumeStop at DoD Site

This updated case study reviews a pilot test to remove PFAS risk via an in situ colloidal activated carbon barrier at Camp Grayling in Crawford County, Michigan, a large year-round military training center operated by the Michigan Army National Guard (MIARNG). Colloidal activated carbon was selected because of the expected rapid reductions of PFAS by removal from the dissolved mobile phase, as well as its expected lower total project costs when compared to operating a mechanical system over a similar time. Download the case study to learn how the colloidal activated carbon permeable reactive barrier treated PFAS to non-detect.

Upcoming Webinar with Matt Burns Showcasing Proven Methods for Saving Time and Money

In this webinar we are pleased to have as a special guest speaker Matt Burns, Technical Fellow and the U.S. Contaminated Land National Service Line Director for WSP. His presentation will discuss proven methods for saving time and money using in-situ activated carbon remediation. He will be joined by Maureen Dooley, Director of Strategic Projects at REGENESIS. This live webinar starts Thursday, October 29th, 2019 at 11am pacific/2pm eastern.

Upcoming Webinar with PFAS Industry Expert, Dr. Grant Carey Presenting on PlumeStop Longevity

In this webinar we are pleased to have as a special guest speaker Grant Carey, Ph.D., President of Porewater Solutions. His presentation will discuss PlumeStop longevity for in-situ PFAS plume treatment. He will be joined by Maureen Dooley, Director of Strategic Projects at REGENESIS, who will discuss in-situ treatment of PFAS using colloidal activated carbon to eliminate PFAS risk at a low cost. This live webinar starts Thursday, November 19th, 2020 at 11am pacific/2pm eastern.

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

September 2020 Newsletter

Client Spotlight: Clayton Sorensen

Clayton Sorensen, Project Geologist with GSI Environmental Inc. (GSI), shares, “I chose a career in environmental remediation because I enjoy applying creative solutions and science to complex problems.” In his current role with GSI, Sorensen works to assess and clean up soil and groundwater on a variety of sites. He continues, “I manage field implementation for investigation and remediation of various constituents in soil and groundwater including PFAS, chlorinated solvents and heavy metals, both in fractured and porous media.”

Subscribe To Our Monthly Newsletters

PetroFix Chosen as Most Cost-Effective Option to Address Petroleum Contaminants at DoD Site

This case study reviews a PetroFix application to address hydrocarbon contaminants at the former Buxton Naval Auxiliary Air Station, located within the Cape Hatteras National Park in the Outerbanks region of North Carolina. The US Navy utilized the site as a submarine monitoring station from 1956 to 1982. The US Coast Guard (USCG) acquired the facility after 1982 and used the site as a logistical, communication, medical, and supply support center. The site contains four areas of investigation which encompass a total area of approximately 50,000 square feet. PetroFix Remediation Fluid was chosen because it is specifically designed to treat PHC plumes stemming from bulk storage, gas station, and UST spills.

Apply Activated Carbon Under Low Pressure to Treat Petroleum Hydrocarbons

7 Reasons to Consider an In-Situ Permeable Reactive Barrier to Treat Groundwater Contaminants

This video outlines 7 reasons to consider an in-situ permeable reactive barrier (I-PRB) to treat groundwater contaminants. If designed intelligently and installed correctly, I-PRBs can be a highly cost-effective and customizable remediation tool that environmental practitioners can use to achieve cleanup goals.

eBook Provides Analysis of Effectiveness of In-Situ Permeable Reactive Barriers

PFAS Webinar Now Available!

In this webinar we were pleased to have as a special guest speaker Rick McGregor, President of InSitu Remediation Services Ltd. His presentation discussed six pilot-scale studies evaluating the in situ treatment of PFAS in groundwater. He was joined by Maureen Dooley, Director of Strategic Projects at REGENESIS, who discussed in situ treatment of PFAS using colloidal activated carbon to eliminate PFAS risk at a low cost.

How Colloidal Activated Carbon Eliminates PFAS Risk and Liability at a Low Cost

PlumeStop colloidal activated carbon utilizes activated carbon finely milled to >2µm (the size of a red blood cell) and suspended in a colloidal fluid to be injected under low pressure into the subsurface. The carbon particles disperse and diffuse, and then adhere to the surface of soil particles, converting contaminated aquifers into purifying filters. The PFAS contamination present in the groundwater is tightly adsorbed onto the PlumeStop in the subsurface, removing it from the groundwater and eliminating the downgradient risk to the region.

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

August 2020 Newsletter

Client Spotlight: John Butillo

As the Engineering Manager for Sovereign Consulting Inc., John Butillo is responsible for bioremediation field application, from initial engineering design with system/plant installations, to maintenance and troubleshooting. He shares, “My technical role focuses primarily on facility engineering, permitting, project design, construction and installation of soil/groundwater remediation and wastewater treatment systems, and waste minimization programs.” Butillo has served as the lead design and implementation project manager and lead engineer on more than 100 soil and groundwater remediation projects. Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

PetroFix Applied at Former Buxton Naval Auxiliary Air Station to Treat Hydrocarbon Contaminants

This video explains the in situ remediation of hydrocarbon contaminants using PetroFix Remedial Fluid at former Buxton Naval Auxiliary Air Station. Due to contaminant level exceedances, the responsible party elected to pursue additional remediation efforts beyond monitored natural attenuation. After thoroughly evaluating remedial options, they selected PetroFix micron-scale liquid carbon amendment to capture and biodegrade the petroleum contaminants. 6,000 pounds of PetroFix were applied using direct push injection at 86 points. In addition to its ability to distribute effectively through the subsurface and reach target treatment zones, PetroFix was selected because it was the most cost-effective and least disruptive remedial approach available for the site.

Apply Activated Carbon Under Low Pressure to Treat Petroleum Hydrocarbons

Third Party Research Article – Six Studies on the In Situ Treatment of PFAS in Groundwater

eBook Provides Analysis of Effectiveness of In-Situ Permeable Reactive Barriers

Upcoming PFAS Webinar – Sign Up Today!

In this webinar we are pleased to have as a special guest speaker Rick McGregor, President of InSitu Remediation Services Ltd. His presentation will discuss six pilot-scale studies evaluating the in situ treatment of PFAS in groundwater. This free webinar begins Wednesday, August 12th, 2020 at 11am pacific/2pm eastern.

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

July 2020 Newsletter

Client Spotlight: Ben Christensen

For Ben Christensen, Project Manager/Professional Engineer with AECOM, pursuing a career which involved working outside and “getting my hands dirty” was a primary motivator. He shares, “I have completed multiple soil and groundwater investigations. I’ve also implemented groundwater and soil remediation by in situ chemical and bio-remediation injections, groundwater pump and treat systems, soil-vapor extraction (SVE) systems, bioventing, and excavation.” In his current role, he manages firm-fixed price projects at Nellis AFB, Offutt AFB, and Scott AFB, that include about 30 sites. Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

Performance-Based Objectives Achieved at Scott AFB

This case study reviews the Corrective Action Plan (CAP) at Scott Air Force Base, a large military base located in Southwestern Illinois that was contaminated with petroleum impacted soil. One month following the application of PetroFix®, contaminant levels reached non-detect. Benzene continued to remain non-detect through March 2020 and the site was recommended for no further action.

Apply Activated Carbon Under Low Pressure to Treat Petroleum Hydrocarbons

ISCO Solution Gets Sites to Closure Quickly

RegenOx® is an injectable, two-part ISCO reagent that combines a solid sodium percarbonate based alkaline oxidant (Part A), with a liquid mixture of sodium silicates, silica gel and ferrous sulfate (Part B), resulting in a powerful contaminant destroying technology. RegenOx directly oxidizes contaminants while its unique catalytic component generates a range of highly oxidizing free radicals that rapidly and effectively destroy a range of target contaminants including both petroleum hydrocarbons and chlorinated compounds.

Remediation Technology Tailored to the Petroleum Industry

ORC Advanced® is an engineered, oxygen release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils. ORC Advanced technology and applications have been tailored around the remediation needs of the retail petroleum industry, and have resulted in decreased time to site closure, and degradation rates accelerated up to 100 times faster than natural degradation rates.

Upcoming PFAS Webinar – Sign Up Today!

In this webinar we are pleased to have as a special guest speaker Rick McGregor, President of InSitu Remediation Services Ltd. His presentation will discuss six pilot-scale studies evaluating the in situ treatment of PFAS in groundwater. This free webinar begins Wednesday, August 12th, 2020 at 11am pacific/2pm eastern.

Featured Article – Cleaning up ‘forever’ chemicals in drinking water not easy task

PlumeStop, a colloidal activated carbon remediation technology from REGENESIS, was recently featured in the Dayton Daily News because of its ability to eliminate risk from PFAS contaminants in groundwater at a low cost compared to other currently available treatment methods. Because PFAS is a growing concern for communities trying to protect public health, PlumeStop is increasingly being applied to halt the spread of PFAS plumes and quickly remove risk. This article written by Ismail Turay Jr. is republished courtesy of the Dayton Daily News.

Upcoming Webinars – Register Today!

REGENESIS is pleased to announce our Summer and Fall 2020 Webinars. This series will feature three special guest presentations from distinguished professionals in the remediation industry. The topics of these webinars include innovative use of a preemptive vapor barrier, six pilot-scale studies evaluating the in situ treatment of PFAS in groundwater, and a case study in which an in situ strategy effectively treated PFAS at a Superfund site.

Vapor Intrusion Webinar Recording Now Available

In this webinar we are pleased to have a special presentation from Jessica Law, PG, Engineering Geologist and Case Manager for the Santa Ana Regional Water Quality Control Board. This presentation discussed a case study outlining the largest residential vapor intrusion investigation in California at the site of a former aerospace manufacturer. Joining Ms. Law is Thomas Szocinski, CEP, Land Science Director of Vapor Intrusion, who shared effective approaches to mitigating vapor intrusion on sites like the one discussed in the featured case study.

Industry Leaders in Applying Remediation Technologies

With decades of application experience, our Field Service Team is strategically located across the country to mobilize and assist on a wide range of sites throughout the US. REGENESIS Remediation Services (RRS) injection trailers are staffed by experienced field scientists and mobilized to every site equipped with a positive displacement injection pump (or similar), capable of producing at least 20 gallons per minute in flow. To learn more about the typical injection setup of the industry-leading RRS application team, download the brochure.

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

June 2020 Newsletter

Client Spotlight: Jeremy Kinman

Jeremy Kinman is Associate Technical Director for Wilcox Environmental Engineering, Inc. Kinman realizes his work is indeed benefitting our planet, while also providing him with a role that is both rewarding and challenging. He shares, “One of the more rewarding aspects of my job is being in a position to assist a client with property redevelopment or obtaining an incident closure letter from the state regulatory agency.” At Wilcox, he started in the field and then transitioned into a project manager role and began designing work plans for investigation and remediation activities for projects he directly managed. Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

Performance-Based Objectives Achieved at Scott AFB

This case study reviews the Corrective Action Plan (CAP) at Scott Air Force Base, a large military base located in Southwestern Illinois that was contaminated with petroleum impacted soil. One month following the application of PetroFix®, contaminant levels reached non-detect. Benzene continued to remain non-detect through March 2020 and the site was recommended for no further action.

PlumeStop Arrests PCE in Fast Moving Aquifer

Turn Polluted Aquifers into Purifying Filters with PlumeStop

PlumeStop Liquid Activated Carbon is a break-through groundwater remediation technology that reduces dissolved phase contaminant plumes in days. Composed of extremely fine particles of activated carbon (1‐2μm) suspended in water through a proprietary dispersion chemistry, PlumeStop flows into the subsurface at low pressure and achieves consistent, reliable distribution – a capability unlike any other form of activated carbon used for groundwater remediation today.

Low-cost Bioremediation of Chlorinated Solvents

HRC is an engineered, hydrogen release compound designed specifically for enhanced, in situ anaerobic bioremediation of chlorinated compounds in groundwater or highly saturated soils. HRC enables enhanced anaerobic biodegradation by adding hydrogen (an electron donor) to groundwater and/or soil to increase the number and vitality of indigenous microorganisms able to perform the naturally occurring process of enhanced reductive dechlorination. Due to its capability of being applied via permanent wells, direct-push, and excavations, this reagent allows for clean, low-cost, non-disruptive application.

Accelerated Treatment of Intermediate Compounds

Bio-Dechlor INOCULUM Plus (BDI Plus) is designed to provide rapid and effective treatment of undesirable anaerobic dechlorination intermediates such as dichloroethene (DCE) and vinyl chloride (VC), and is a low-cost means of enhancing the anaerobic biodegradation process. Once in place, this microbial consortium accelerates the rate of chlorinated contaminant degradation from parent compounds to intermediates like DCE and VC and completely through to harmless end products such as ethene and ethane. It is highly compatible with a range of electron donors.

eBook: Zero-Valent Iron Frequently Asked Questions (FAQ)

The following frequently asked questions about zero-valent iron (ZVI) are taken from the questions and answers portion of a webinar given by John Freim PhD, ZVI Product Manager and Director of Materials Science at REGENESIS. Dr. Freim discussed the benefits of using zero valent iron as a powerful remediation amendment for the in situ remediation of chlorinated solvents. To learn about how ZVI works and the benefits of sulfidation, download the eBook.

Integrated Remediation of a Mixed Pesticides, TPH and VOC Plume at a Former Industrial Site in United Kingdom

This video explains the in situ remediation at a former industrial site of significant groundwater contamination: petroleum hydrocarbons, volatile organic compounds including BTEX, trimethylbenzene, and a mix of organochlorine pesticides, including pentachlorophenol, Lindane (gamma-HCH) and Dieldrin. An environmental solution consisting of multiple in situ remediation approaches was designed and implemented to meet the groundwater cleanup targets required as part of the property lease surrender process. Soilfix worked closely with REGENESIS on this challenging project. Great results were achieved within a tight time-scale on behalf of the FTSE100 company and their consultant Ramboll, resulting in successfully achieving the client’s project goals.

Upcoming Vapor Intrusion Webinar – Sign Up Today!

In this webinar we are pleased to have a special presentation from Jessica Law, PG, Engineering Geologist and Case Manager for the Santa Ana Regional Water Quality Control Board. This presentation will discuss a case study outlining the largest residential vapor intrusion investigation in California at the site of a former aerospace manufacturer. Joining Ms. Law will be Thomas Szocinski, CEP, Land Science Director of Vapor Intrusion, who will share effective approaches to mitigating vapor intrusion on sites like the one discussed in the featured case study. This free webinar begins Tuesday, June 23rd, 2020 at 11am pacific/2pm eastern.

PFAS Webinar Recording Now Available!

In this webinar we were pleased to have a special presentation from Ned Witte, Attorney at Godfrey & Kahn, S.C. Ned’s presentation discussed current trends and best practices for performing due diligence to manage PFAS liability risk. He will be joined by Ryan Moore, PFAS Program Manager at REGENESIS, who discussed proven, low-cost in situ remediation solutions to mitigate risk from PFAS contamination in groundwater. The recording of this webinar is available now.

NOTE: This webinar has been approved for Continuing Legal Education (CLE) by the Supreme Court of Ohio Commission on Continuing Legal Education.

A New Resource for Your End User Clients

This eBook outlines 5 reasons remediation of PFAS contaminated sites is vital to both human health and the global economy. Based on a wide-ranging report from the Nordic Council of Ministers entitled The Cost of Inaction Linked to PFAS Exposure, the report had the dual purposes of estimating the costs to society related to the negative impacts on human health and the environment due to PFAS exposure as well as to highlight the economic case for taking effective and timely action to manage the risks posed by these negative impacts. This eBook provides key takeaways from the report as well as highlighting cost-effective measures that communities can consider to treat PFAS liability and risk.

Guest Author Series – Part 2

REGENESIS is pleased to present an environmental article series from guest author, Benjamin Alter, leading environmental science author and Senior Vice President with GZA GeoEnvironmental, Inc. In this four-part series, Ben will provide an in-depth look at Brownfields. The second article is available now.

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

May 2020 Newsletter

Client Spotlight: Tyler Evans

As a hydrogeologist for Hargis + Associates, Inc., a regional engineering and hydrogeology consulting firm and valued REGENESIS client, Tyler Evans enjoys the challenge of utilizing his experience in environmental remediation in a variety of situations, especially under challenging circumstances. In his role with Hargis + Associates, Evans manages and conducts groundwater sampling of monitor wells and extraction wells associated with groundwater remediation systems for several Fortune 500 companies. He also oversees the installation of monitoring wells using several methods of drilling. Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

Remediation of TCE Plume Speeds Sale of Brownfield Site

This case study reviews a former manufacturing site in Fullerton, CA, where a trichloroethylene (TCE) plume contaminated the groundwater and prevented the sale of the brownfield site. In order to complete the remediation and move forward with the sale, Hargis + Associates worked with REGENESIS to develop an in situ chemical reduction (ISCR) design to address the plume. REGENESIS designed an injection plan using micron-scale Zero Valent Iron (ZVI) due to its proven ability to effectively reduce contaminant levels within a subsurface environment. In just one month following the application, monitoring shows successful reduction of the TCE plume.

ZVI Optimized for Reactivity and Superior Distribution

A Guide to 6 Key Advantages and Tax Incentives for Opportunity Zone Properties and Investment Funds

Qualified Opportunity Zones (QOZ) are designed to spur economic development and job creation in distressed communities throughout the country by providing tax benefits to investors who invest eligible capital into these communities. This ebook provides a high-level overview of the Opportunity Zone program, a guide to six of some of the most meaningful changes for land redevelopment included in the final regulations, and information on where to turn for quick and cost-effective assistance when it comes to environmental remediation. To learn about some of the key advantages to recent Opportunity Zones regulatory changes, download the eBook.

Upcoming PFAS Webinar – Sign Up Today!

In this webinar we are pleased to have a special presentation from Ned Witte, Attorney at Godfrey & Kahn, S.C. Ned’s presentation will discuss current trends and best practices for performing due diligence to manage PFAS liability risk. He will be joined by Ryan Moore, PFAS Program Manager at REGENESIS, who will discuss proven, low-cost in situ remediation solutions to mitigate risk from PFAS contamination in groundwater. This free webinar begins Thursday, May 14th, 2020 at 11am pacific/2pm eastern.

Technology Webinar Recording: Optimizing ZVI

In this webinar we were pleased to have a special presentation from John Freim, PhD, ZVI Product Manager and Director of Materials Science at REGENESIS. Dr. Freim discussed the benefits of using zero-valent iron (ZVI) as a powerful remediation amendment for the in situ remediation of chlorinated solvents. He was joined by James Cobb, CSP, RSO, Director of Health and Safety at REGENESIS, who discussed safety procedures being implemented by REGENESIS in response to COVID-19.The recording of this free webinar is available now.

COVID-19 Safety Webinar Recording Now Available

In this webinar we were pleased to have a special presentation from James Cobb, CSP, RSO, Director of Health and Safety at REGENESIS. During this webinar, James discussed COVID-19 safety best practices for environmental professionals who are working in the field, as well as those who are working from home. He was joined by Will Clogan, Remediation Services Project Manager at REGENESIS, who shared COVID-19 safety processes being implemented by REGENESIS Remediation Services (RRS) during field applications of REGENESIS technologies. The recording and slides from this free webinar are available now.

Guest Author Series – Part 1

REGENESIS is pleased to present an environmental article series from guest author, Benjamin Alter, leading environmental science author and Senior Vice President with GZA GeoEnvironmental, Inc. In this three-part series, Ben will provide an in-depth look at Brownfields. The first article is available now.

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

April 2020 Newsletter

Client Spotlight: Tim McDonald

For Tim McDonald, Vice President with Environmental Services Group, Inc. (ESGI) a career in environmental remediation evolved after years of extensive experience in the oil and gas industry. He shares, “The scientific and engineering mechanisms that can be applied to both protect the environment and prevent damage from industrial activity are very appealing.” In his current role at ESGI, McDonald is responsible for engineering and environmental design work for permit acquisitions that include mining, air, and water discharge. He also manages bioremediation and environmental cleanup that includes soil and water sampling, as well as the remediation of soil and water contamination. Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

Global Retailer Enters Into Elective Site Cleanup Agreement and Achieves No Further Action

This case study reviews the site of a global retailer based in Arkansas, where historic offsite dry cleaning operations caused tetrachloroethylene (PCE) contamination in the groundwater. A previous bioremediation attempt successfully remediated a majority of the site, but one persistent well remained. Environmental Services Group, Inc. (ESGI) partnered with REGENESIS to design a bioremediation plan that would apply PlumeStop Liquid activated Carbon, HRC and BDI Plus to eliminate the remaining contaminants of concern (COCs). After applications of these technologies from REGENESIS, all COCs were below the acceptable threshold levels, and as a result the site achieved No Further Action (NFA) in January of 2020.

Turn Polluted Aquifers into Purifying Filters with PlumeStop

Low-cost Bioremediation of Chlorinated Solvents

HRC® is an engineered, hydrogen release compound designed specifically for enhanced, in situ anaerobic bioremediation of chlorinated compounds in groundwater or highly saturated soils. HRC enables enhanced anaerobic biodegradation by adding hydrogen (an electron donor) to groundwater and/or soil to increase the number and vitality of indigenous microorganisms able to perform the naturally occurring process of enhanced reductive dechlorination. Due to its capability of being applied via permanent wells, direct-push, and excavations, this reagent allows for clean, low-cost, non-disruptive application.

Accelerated Treatment of Intermediate Compounds

![]() BioDechlor INOCULUM® Plus (BDI Plus) is designed to provide rapid and effective treatment of undesirable anaerobic dechlorination intermediates such as dichloroethene (DCE) and vinyl chloride (VC), and is a low-cost means of enhancing the anaerobic biodegradation process. Once in place, this microbial consortium accelerates the rate of chlorinated contaminant degradation from parent compounds to intermediates like DCE and VC and completely through to harmless end products such as ethene and ethane. It is highly compatible with a range of electron donors.

BioDechlor INOCULUM® Plus (BDI Plus) is designed to provide rapid and effective treatment of undesirable anaerobic dechlorination intermediates such as dichloroethene (DCE) and vinyl chloride (VC), and is a low-cost means of enhancing the anaerobic biodegradation process. Once in place, this microbial consortium accelerates the rate of chlorinated contaminant degradation from parent compounds to intermediates like DCE and VC and completely through to harmless end products such as ethene and ethane. It is highly compatible with a range of electron donors.

Technology Webinar Recording: Optimizing ZVI

In this webinar we were pleased to have a special presentation from John Freim, PhD, ZVI Product Manager and Director of Materials Science at REGENESIS. Dr. Freim discussed the benefits of using zero-valent iron (ZVI) as a powerful remediation amendment for the in situ remediation of chlorinated solvents. He was joined by James Cobb, CSP, RSO, Director of Health and Safety at REGENESIS, who discussed safety procedures being implemented by REGENESIS in response to COVID-19.The recording of this free webinar is available now.

PFAS Webinar Recording: Key PFAS Practice Leaders Share Their Experience

Working Remotely? Visit Our Remediation Training Library

At REGENESIS, we know that many environmental firms are seeing a reduction in field work as we respond to COVID-19 and most firms have staff working remotely. Many companies are using this time to focus on staff training and getting abreast of new technologies and regulations. So we wanted to bring your attention to our library of pre-recorded webinars that we provide on our website at no charge. Topics include PFAS, as well as remediation of chlorinated solvents and petroleum hydrocarbons in soil and groundwater, and vapor intrusion regulations and mitigation. We’ll also provide certificates of attendance for any webinar viewed upon request by emailing marketing@regenesis.com.

Adapting Our Processes in Response to Coronavirus to Provide Continued Support to Our Clients

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

March 2020 Newsletter

Client Spotlight: Cody Martin

As Project Environmental Scientist with C&S Engineers, Inc., Cody Martin’s responsibilities focus on Brownfield Cleanup Program (BCP) sites. The program incentivizes the remediation of properties that have been left vacant or abandoned for many years. He shares, “I help private developers manage their way through the BCP process. This means balancing their needs with the requirements of the New York State Department of Environmental Conservation (NYSDEC). I help make it possible to repair the damage, cleanup the petroleum spill or remove the contaminated waste, and improve the health of the environment, while at the same time encouraging economic growth.” Learn more in our client spotlight.

Subscribe To Our Monthly Newsletters

Excavation With RegenOx Successfully Treats PHC Plume

This case study reviews a former gas station site in Buffalo, New York that required remediation due to leaking underground storage tanks. Together with REGENESIS, C&S Consulting designed an in situ remediation strategy to target the residual contaminant plume. RegenOx® in situ chemical oxidant was chosen because of its ability to target petroleum hydrocarbons and its non-corrosive properties. As part of the New York State Department of Environmental Conservation (NYSDEC) Brownfield Cleanup Program, C&S designed a complex remediation program to ensure a quick and affordable solution. Successful remediation enabled the construction of a 350,000 sq. ft. $110 million facility at the Buffalo Niagara Medical Campus.

ISCO Solution Gets Sites to Closure Quickly

Upcoming PFAS Webinar – Sign Up Today!

In this webinar we are pleased to have as a special guest speaker Jack Sheldon, Senior Remediation Specialist at Antea Group, and Caron Koll, PG, LSP, and PFAS Lead at Antea Group. Their presentation will discuss lessons learned from a decade of experience working with PFAS contaminants in groundwater. Through more than a decade of developing sampling programs and interpreting PFAS analytical data, many lessons have been learned and this webinar will focus on a few of those lessons. This free webinar begins Wednesday, March 25th, 2020 at 11am pacific/2pm eastern.

Webinar Recording Now Available

Land Science is pleased to present a webinar with vapor intrusion experts Dr. Blayne Hartman of Hartman Environmental Geoscience and Dr. Mark Kram of Groundswell Technologies. During this webinar presentation, they discuss updates regarding vapor intrusion pathway issues, including regulatory updates and the use of vapor intrusion continuous monitoring technology. They are joined by Tom Szocinski, CEP, Director of Vapor Intrusion at Land Science, who discusses technologies to mitigate vapor intrusion.

New Battelle Sponsorship Opportunity

Questions?

REGENESIS has remediation experts based worldwide to assist you in your brownfield site cleanup. As the technology leader in advanced bioremediation solutions, we can help ensure success on your next remediation project. Use the map on our website to find your regional REGENESIS contact today.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español