Innovative In Situ Application of PetroCleanze Uses Horizontal Wells

Case study highlights:

- Innovative design and creative solution using horizontal wells to apply PetroCleanze and minimize daylighting

- The horizontal well system allows for the active gas station to continue to conduct business without disruptions

- Staying open during remediation efforts saved gas station owners an estimated $8,000 per day

- PetroCleanze was successfully applied despite the challenging lithology and shallow bedrock

This case study reviews an innovative remediation design at a site that is using two horizontal wells which will administer a total of four injection events, with enhanced fluid recovery (EFR) events being performed before and after each injection. BTEX contamination and free-phase product from a petroleum release was discovered in the groundwater at an active gas station in Colorado. After previous remediation attempts from prior consultants, CGRS, Inc., Paragon Consulting Group, Inc., the Colorado Division of Oil and Public Safety (OPS), and REGENESIS® collaborated to create a design that would successfully remediate the persistent groundwater contamination and free-phase product.

Combined Remedy Treats TCE Plume at Aerospace Site

Case study highlights:

- Combined remedy was three times the cost savings vs. alternative remedial technologies being considered

- Completed the application event ahead of schedule

- Successful reductions in cVOCs observed

This case study reviews an aerospace manufacturing facility in Southern California that required remediation for a deep and heavily impacted Trichloroethene (TCE) plume. The extensive depth and size of the plume contributed to the difficulty facing remediation efforts, with much of the contaminant plume extending offsite. Alta Environmental and REGENESIS began developing an approach to remediate this site in 2012. After conducting pilot tests, they concluded that Enhanced In-Situ Bioremediation (EISB) technology was both cost-effective and feasible for successful remediation of this site. The observation wells continue to be sampled quarterly and are displaying successful reductions in cVOCs.

In Situ treatment of toluene in groundwater, Helsingborg, Sweden

In Situ reagent barriers (HRC) treat contaminated groundwater in sandstone under a schoolRead More

Integrated in situ remediation of honing oil in a chalk aquifer, UK

In Situ reagent barriers (HRC) treat contaminated groundwater in sandstone under a schoolRead More

In Situ pilot remediation of gasworks impacted groundwater, Stockholm, Sweden

Introduction

In the north-east of Central Stockholm, a historical industrial site was earmarked for redevelopment. Part of the site comprised a former gasworks, where historical operations have caused a complex mix of contaminants to impact the surrounding soil, groundwater and shoreline sediments.

The large site is due to be redeveloped in a series of parcels including a road, industrial park, residential homes and schools. Remediation is required to ensure the human health risk is removed as part of the restoration of the site. The impacted groundwater also represents an environmental risk and requires treatment. Risk assessments were used to determine that remediation was required to a depth of 20m BGL. The geology of the site is heterogeneous, comprising a shallow made ground, a clay layer and underlying coarse sands.

The sands are highly impacted with a range of gas works contamination included creosote NAPLs and high levels of benzene. The saturated clays are also impacted with dissolved phase contamination. Due to contaminants, concentrations and superficial geologies, a range of remedial methods would be required to ensure the most appropriate was used in each scenario. Therefore, RGS Nordic engaged REGENESIS to design a series of pilot tests utilising several in-situ methods. The results from these trials would then be used to shape the full-scale remediation strategy for the entire gasworks site area.

Combined In Situ Remediation Approach and Planning

REGENESIS proposed a pilot-scale combined remediation approach comprising:

- Enhanced desorption using PetroCleanze to target high concentrations of soil-bound contaminants of concern (COC’s) in the sands,

- In Situ Chemical Oxidation (ISCO) using both RegenOx and PersulfOx to target medium to high dissolved phase and soil-bound PAHs in the sandy soil, and

- Enhanced aerobic degradation using ORC-Advanced to target the low dissolved phase benzene and naphthalene concentrations in the clay.

Results

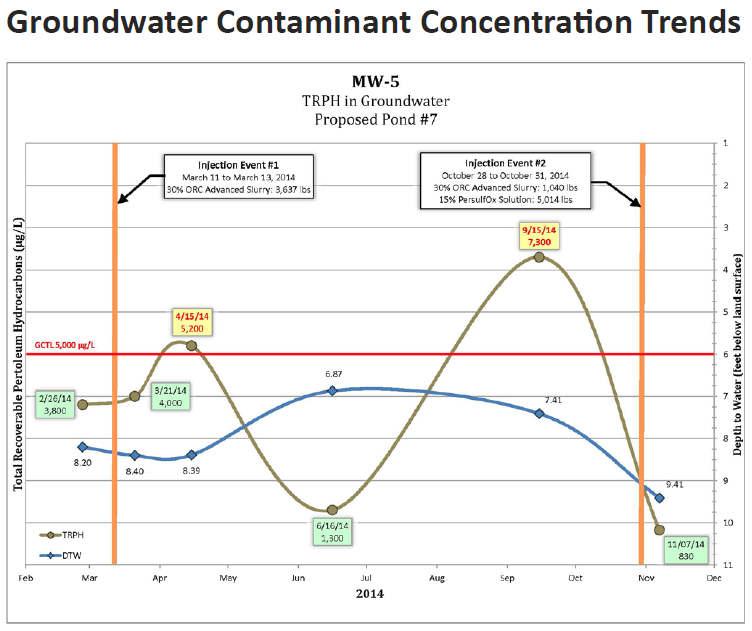

Groundwater samples were collected 3-4 months after the application of REGENESIS remediation products, see graphs 1 to 3. The results are displayed below

Enhanced Desorption using PetroCleanze

>95% reduction in dissolved phase benzene was achieved with the addition of PetroCleanze. The treatment for PAHs was found to be less effective, primarily due to the low baseline PAH concentrations which were below the optimum treatment concentration range for PetroCleanze.

Graph 1– Effect of PetroCleanze application on dissolved Benzene concentrations

ISCO using RegenOx and PersulfOx

>90% reduction in dissolved phase benzene and PAHs was observed using PersulfOx. In the RegenOx trial, dissolved benzene concentrations were found to decrease by 80%, while PAH levels increased slightly, potentially due to large volumes of desorbed COCs being released into groundwater post-treatment.

Enhanced Aerobic Biodegradation using ORC-Advanced

A sustained reduction in Naphthalene and benzene (despite suspected influx into the test area) was achieved using ORC-Advanced in the saturated clay.

Graph 2– Effect of PersulfOx application on PAH concentrations

Conclusion

- A wide range of contaminant concentrations were treated effectively using a combined in-situ remediation approach.

- Substantial reductions in COC concentrations were achieved despite the challenging geological setting.

- The results from the pilot tests show that all areas of the gasworks site can be successfully remediated in-situ using REGENESIS remediation products, providing significant cost savings when compared with conventional techniques

Graph 3– Effect of ORC-A application on PAH concentrations

ZVI Applied To Remediate DoD Superfund Site

Case study highlights:

- Successful application of colloidal zero valent iron through well system

- At 3 years post-injection, the presence of ethene signals active biodegradation

- Aqueous suspension of colloidal zero valent iron effectively reduced contaminant levels

- Remediation was successfully coordinated in the middle of an active Air Force base

This case study reviews the remediation of dichloroethane (1,2-DCA) and Trichloroethylene (TCE) using colloidal zero valent iron (ZVI) at Tinker Air Force Base, a major United States Air Force base located in Oklahoma City, Oklahoma. This remediation project was undertaken near former Waste Pit 1 and addressed a co-mingled plume of 1,2-DCA with lesser amounts of TCE. The 1,2-DCA concentrations in the plume were as high as 500 mg/L. The remediation included an application of emulsified vegetable oil (EVO), an aqueous suspension of colloidal zero valent iron (MicroZVI Precursor), with small amounts of fertilizer and B12. Typically, zero valent iron cannot be applied through well systems. However, due to the small particle size of the zero valent iron, this application was successfully applied through the existing wells. At 3 years post-injection, the contaminant levels remain near zero with the presence of ethene indicating continuous biodegradation.

Significant Reduction in VOCs Achieved at Rail Site

Case study highlights:

- First application of PlumeStop® and AquaZVI™ globally

- Despite wintery weather conditions at the Rail Site in Northern Quebec, the amendment delivery and distribution was successful

- Over 95% decrease in dissolved and saturated soil VOC concentrations

- Thorough data analysis including ISMs and CSIA confirmed definite contaminant degradation

This case study reviews a contaminated rail site in Canada that had released chlorinated solvents in groundwater. WSP conducted a pilot test at the site to assess the applicability of a brand-new technology that optimizes delivery of amendments using hydrocolloids. The pilot test would determine the applicability of a passive treatment barrier using PlumeStop and AquaZVI. A combined remedy approach was chosen because it optimizes the use of colloidal activated carbon and zero valent iron, allowing for the highest treatment efficiency at the lowest possible cost. After conducting the pilot test, data for samples collected within the treatment barrier indicated significant contaminant concentration decreases in groundwater and saturated soil.

In Situ Remedy Addresses PFAS Risk at Superfund Site

Case study highlights:

- Estimated savings of $400,000 annually as a result of halting pump and treat operations

- PlumeStop quickly reduced PFOS/PFOA levels and in combination with AquaZVI eliminated VOC contaminant concentrations

- Extension of the popular Rails to Trails route now runs through the property, as a result of successful remediation efforts

This case study reviews remedial programs undertaken at the Solvents Recovery Service of New England (SRSNE), where soil and groundwater were contaminated with VOCs and PFAS contaminants. The site was placed on the National Priorities List in 1983 and by 1991, all activities stopped as the site ceased operations. Since shutting down, the site has benefited from significant remediation efforts. In 2018, an innovative remedial approach incorporated natural attenuation with the use of PlumeStop® to work with an existing sheet pile structure to limit the mobility of the plume and effectively treat contaminant concentrations. PlumeStop quickly reduced PFOS/PFOA levels and in combination with AquaZVI® eliminated VOC contaminant concentrations. It is estimated that the PRP group involved will save $400,000 annually with the shut down of the pump and treat system on site.

PlumeStop® and ORC Advanced® Applications Achieve Successful Results in 24 Hours

Project Highlights

- Successful rapid reduction of petroleum hydrocarbon contaminant concentrations in soil and groundwater completed within approximately 24 hours.

- In Situ injection application of PlumeStop® Liquid Activated Carbon and ORC Advanced technologies assist REGENESIS strategic partner in bringing closure to facility identified as Leaking Underground Storage Tank (LUST) site

- Petroleum hydrocarbon concentrations (PHCs) in groundwater and soil reduced below Washington Department of Ecology’s (Ecology) Model Toxics Control Act (MTCA)

Project Summary

An active gasoline station in Bothell, Washington was listed as a hazardous Leaking Underground Storage Tank (LUST) site by the State of Washington Department of Ecology (Ecology) after two subsurface investigations detected petroleum hydrocarbon-impacted soil and groundwater. Entering into the state’s Voluntary Cleanup Program (VCP) in 2001, the site continuously failed to meet regulatory requirements defined in the Model Toxics Control Act (MTCA), despite years of cleanup efforts using a soil vapor extraction (SVE) system and an air sparge (AS) system to remove contaminant concentrations from beneath the site. Charged with remediation, Antea Group partnered with REGENESIS to implement a solution, which included in situ injection applications using PlumeStop and ORC Advanced technologies.

Technology Applied

PlumeStop – an innovative groundwater remediation technology designed to address the challenges of excessive time and end-point uncertainty in groundwater remediation. PlumeStop is composed of very fine particles of activated carbon (1-2µm) suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix binding to the aquifer matrix, rapidly removing contaminants from groundwater, and expediting permanent contaminant biodegradation.

ORC Advanced (ORC-A) – an engineered, oxygen-release compound designed specifically for enhanced, in situ aerobic bioremediation of petroleum hydrocarbons in groundwater and saturated soils that, upon contact with groundwater, produces a controlled-release of molecular oxygen (17% by weight) for periods of up to 12 months in a single application, accelerating aerobic biodegradation processes up to 100 times faster than natural degradation rates.

Background

Despite the installation of three groundwater monitoring wells (MW-1 through MW-3) in 2002 and five additional monitoring wells (MW-4 through MW-8) in 2003, concentrations of total petroleum hydrocarbons in TPH-g and BTEX in the western portion of the site exceeded the Model Toxics Control Act (MTCA) Method A cleanup levels. In 2004, a soil vapor extraction (SVE) system and an air-sparge (AS) system were installed and by 2005 an estimated 2,076 pounds of total volatile hydrocarbons (TVH) were extracted, with concentrations falling below MTCA Method A cleanup levels for two consecutive quarters. Laboratory analysis of groundwater samples collected during the following two quarters, however, indicated that hydrocarbon compounds in groundwater had increased in several monitoring wells.

Challenge

The AS system was restarted in October, 2005 and operated on an approximate 2-week-on and 2-week-off cycle through February, 2009, when it was shut down based on non-detectable hydrocarbon concentrations in all but one groundwater monitoring well, MW-3. As a remediation strategy to address TPH-g and benzene impacts that remained in well MW-3, sulfate injection was proposed. However, due to high sulfate concentrations observed in the down-gradient monitoring well, MW-9, the sulfate injections were suspended in November of 2012 and evaluations of other chemical injection methods were proposed.

REGENESIS Remediation Services (RRS) recommended PlumeStop injection and completed two soil borings for design verification testing in November, 2015. Soils on-site were primarily sand and gravel, with two, 4-6” clayey silt layers—one at approximately five feet and the other at 10.5 feet below ground surface (bgs). Based on field screening with photoionization (PID), contamination appeared to be concentrated at the 8-9 feet depth interval, a point at which soil increasingly hardens. With results of a laboratory analysis, RRS modified the design, adjusting the vertical treatment interval from 5-12 feet below ground surface to 7-11 feet, with the concentrations and quantities of PlumeStop and ORC-A remaining unchanged.

Solution

REGENESIS Remediation Services (RRS) injected approximately 200 gallons of PlumeStop 6,000 ppm solution into on-site wells IW-1 and SVE-1 December, 2015. Using strategically placed point locations to rapidly reduce contaminant concentrations, Direct Push Technology (DPT) was employed to advance injection points throughout the treatment zone at each respective injection point location. The following day, the solution was increased to 12,000 ppm, for a total of 835 gallons of PlumeStop solution (as applied with water) injected within the targeted treatment interval to deliver the full volume of remediation chemistry and complete the application on schedule.

A total of nine (9) PlumeStop DPT injection points were cleared to 5 feet below ground surface pre-injection, and during the course of the injection seven (7) point locations were advanced to a depth of 11 feet below ground surface and retracted to a depth of 7 feet below ground surface using 1.50 inch outer diameter (O.D) Geoprobe® injection rods with retractable screen tooling.

Additionally, 120 pounds of ORC-A were applied at approximately 30% solution (w/w) in cleared boreholes via a backfilling method, which involved drilling to the target depth, retracting the rods and pouring the ORC-A slurry down open boreholes to approximately 5 feet below ground surface in order to properly abandon points.

Results

During the course of the injection and at the end of the application, increases in groundwater levels were observed in monitoring wells MW-3 and MW-9 in the treatment area. Additionally, increases in ORP (oxidation reduction potential) were observed in MW-2, MW-3, MW-6, MW-7, MW-8, and MW-9. Increases in dissolved oxygen were also noted post-injection in MW-2, MW-3, MW-6, MW-7, MW-8, and MW-9.

The successful and rapid reduction of petroleum hydrocarbon contaminant concentrations in soil and groundwater was achieved within approximately 24 hours, despite difficulty injecting the material via direct-push injection points. With field modifications, RRS was able to not only mitigate surfacing issues by switching to injection via injection well application but also observe the desired distribution of the remediation chemistry in the subsurface.

In the same way the State of Washington Department of Ecology continues to take steps and implement tools that will streamline the cleanup process even further, REGENESIS recognizes the critical need for cost-effective, sustainable and environmentally sound remediation solutions. Whether pioneering new in situ technologies in the lab or rolling up its sleeves in the field to ensure a successful project outcome, REGENESIS remains committed to advancing the remediation industry for the benefit of its partners as well as for the future of the world at large.

How PlumeStop® Brings Sites to Permanent Closure

PlumeStop rapidly removes contaminants from groundwater and stimulates their permanent degradation. This exciting, turn-key solution offers several key benefits for addressing brownfield site treatment, including:

- Rapid reduction of dissolved-phase plumes

- Distribution of widely under low injection pressures

- Achievement of stringent groundwater clean-up standards

- Providing a long-term means of addressing matrix back–diffusion

- Elimination of excessive time and end-point uncertainty associated with groundwater remediation

PlumeStop is composed of very fine particles of activated carbon (1-2µm), suspended in water through the use of unique organic polymer dispersion chemistry. Once in the subsurface, the material behaves as a colloidal biomatrix, binding to the aquifer matrix, rapidly removing contaminants from groundwater, and expediting permanent contaminant biodegradation. This unique remediation technology accomplishes treatment with the use of highly dispersible, fast-acting, sorption-based technology which captures and concentrates dissolved-phase contaminants within its matrix-like structure. When contaminants are sorbed onto the regenerative matrix, biodegradation processes achieve complete remediation at an accelerated rate, leading to successful site treatment.

Former Taxi Maintenance Site Successfully Treated with Enhance d Anaerobic Biodegradation and Bioaugmentation

Project Highlights

- Combined introduction of HRC® hydrogen release compounds and BDI Plus® bioaugmentation cultures resulted in reduction in chlorinated solvent concentrations, meeting site goals

- Successful remediation permitted redevelopment of the site into an elementary school

Project Summary

A former taxi maintenence facility located in Los Angeles, California was used as a garage and maintenance facility containing seven underground storage tanks (USTs), four hydraulic hoists, an elevator, a clarifier, and a spray paint booth. Environmental assessment related to the planned redevelopment of the garage and nearby commercial properties and residences revealed contamination of the soil and groundwater beneath the site with trichloroethene (TCE) and 1,2-dichloroethene (1,2-DCE) due to release from the former USTs and paint shop areas.

Under the jurisdiction of the California Department of Toxic Substance Control, an enhanced anaerobic biodegradation approach in conjunction with bioaugmentation was developed to remediate the chlorinated solvent contamination. This approach combined the introduction of the dechlorinating microcosm BDI Plus® with the application of supporting hydrogen release compounds 3-D Microemulsion® and HRC Primer®. Following treatment of the site, reduction in TCE and 1,2-DCE concentrations have been observed after four quarters of postremediation monitoring. Microbial data supports the benefits of the bioaugmentation effort by showing a steep increase in dehalococcoides populations, which increased by nearly four orders of magnitude. In addition, all geochemical parameters are in range for a reductive state.

Technology Description

3-D Microemulsion is an engineered electron donor material that offers a novel three-stage electron donor release profile, pH neutral chemistry, and is delivered on-site as a factory-emulsified product.

HRC Primer is derivative of the standard Hydrogen Release Compound product and is designed to provide a controlled but fast release of hydrogen to assist in initiating anaerobic biodegradation.

Bio-Dechlor INOCULUM Plus (BDI Plus) is an enriched natural microbial consortium containing species of Dehalococcoides sp. (DHC). This microbial consortium has since been enriched to increase its ability to rapidly dechlorinate contaminants during in situ bioremediation processes.

Results

Reduction of TCE and 1,2-DCE concentrations by enhanced anaerobic biodegradation and bioaugmentation facilitated the redevelopment of a former taxi garage and maintenance facility. Following a reduction in contaminant concentrations, the site was redeveloped to an elementary school.

Americas

Americas Europe

Europe Français

Français Deutsch

Deutsch Italiano

Italiano Español

Español